Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

No matches, but we are here to help; Search Service

Workover

Slickline

Slickline Halliburton Tools

Introducing the Canaweld CAD 81 Capacitor Discharge Stud Welding System: Power and Precision Unleashed! When it comes to high-performance stud welding, the Canaweld CAD 81 stands in a league of its own. Harnessing the cutting-edge technology of Capacitor Discharge (CD) stud welding, this welding system offers unparalleled precision, speed, and efficiency, making it the ultimate choice for welders in the oil and gas industry. Precision in a Blink - Capacitor Discharge Stud Welding The Canaweld CAD 81 utilizes a direct-current arc from a capacitor, allowing for weld times as quick as 1 to 6 milliseconds. The result? Seamlessly welded studs with no burn-through on the opposite side, even with very thin metals. Perfect for smaller diameter studs, pins, non-standard materials, and when precision is paramount. Compact Yet Powerful - Unmatched Welding Capacity Don't be fooled by its compact design; the Canaweld CAD 81 boasts a full 5/16-inch (M8) welding capacity, making it the most compact and versatile system on the market. Its microprocessor control ensures precise and consistent welding performance, while the enhanced charging circuit with a high output transformer maximizes its duty cycle, offering you unmatched welding power in a lightweight package. Safety and Ease of Use - User-Friendly and Efficient The Canaweld CAD 81 is designed with your safety and convenience in mind. With enhanced user feedback, including safety and fault codes, you can weld with confidence and peace of mind. The system comes complete with everything you need, including the gun, two ground cables, collets, changing tools, and a convenient carrying case for easy transportation. Features That Make a Difference Let's take a look at some of the remarkable features of the Canaweld CAD 81: • Weld Range: Accommodates US Stud Size #4 – 5/16”, Metric Stud Size (M3-M8), Stud diameter 0.112″ – 0.312″ • Input Power 1~115/230, 50/60Hz (internally switchable) • 81,000uf Capacitance for rapid and powerful welds • Portable and Lightweight: Weighing only 25 lbs., take it anywhere the job demands • Ergonomic Design: Designed for comfort and ease of use during extended welding sessions • Heavy-Duty Cable Set: Ensures robust and reliable connections • Dual Ground Cable: For added safety and efficiency • Fully Adjustable Leg Set: Achieve the perfect welding angle for every job • Diagnostic LEDs: Easy troubleshooting and maintenance The Canaweld CAD 81 - Empowering Welders in the Oil and Gas Industry At Canaweld, we take pride in providing cutting-edge welding machines and accessories that meet the unique demands of the oil and gas industry. The CAD 81 exemplifies our commitment to excellence, innovation, and your welding success. Unleash the Power of Precision and Performance with the Canaweld CAD 81 Capacitor Discharge Stud Welding System. Empower your welding journey with Canaweld - Your Partner in Welding Excellence!

Buy

In Stock

Manufacturer

New

ASME

Land Freight

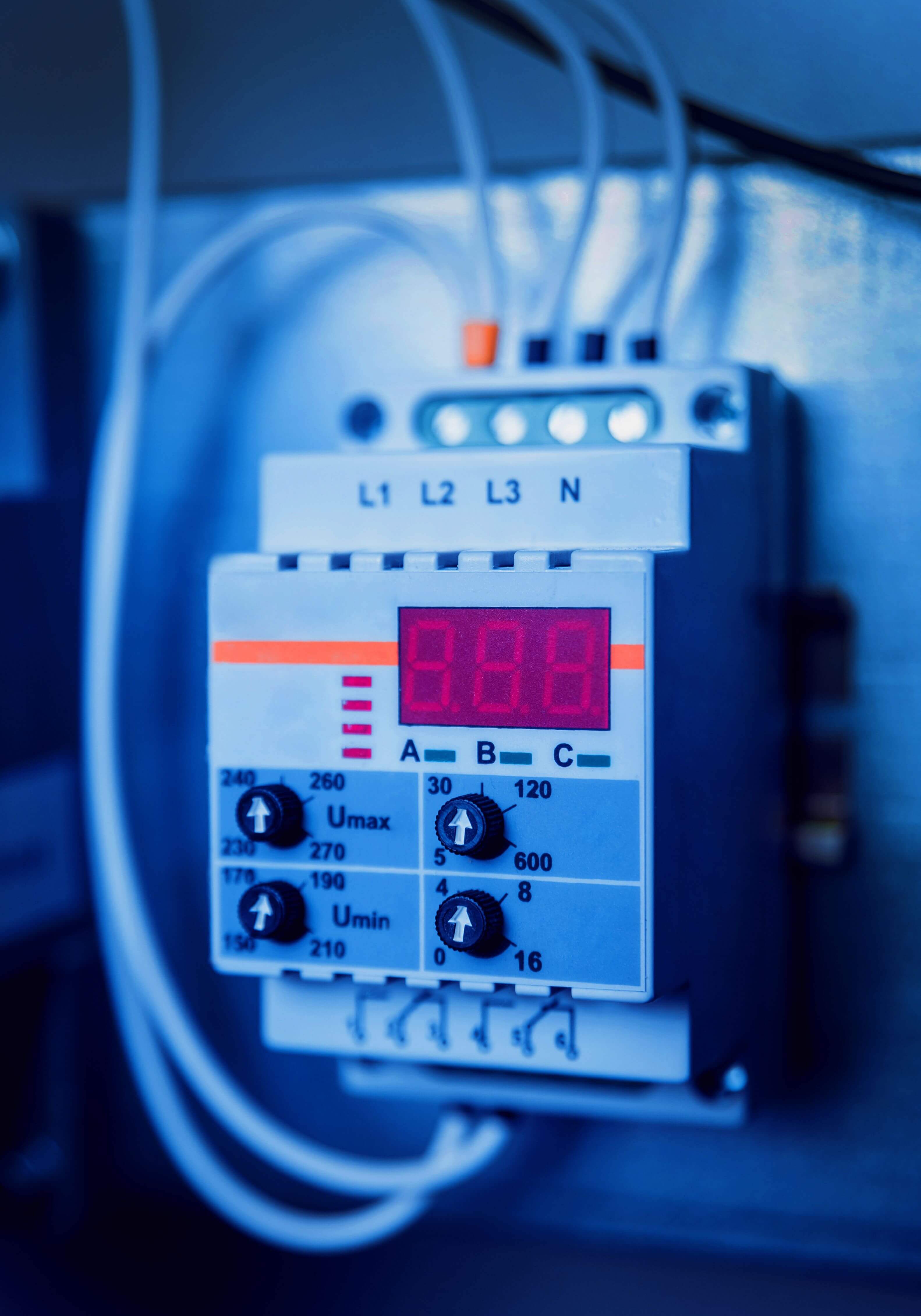

Elevate Your Energy Sector with ELEKS: Unleashing SCADA Systems and More In the realm of energy and utilities, where stability, efficiency, and innovation reign supreme, ELEKS emerges as your strategic partner, offering a powerhouse of expertise that redefines industry standards. Our proficiency in supervisory control and data acquisition (SCADA) systems is poised to transform your operations, ensuring unwavering power delivery, cost optimization, and the seamless integration of cutting-edge trends like smart grids. Prepare to embark on a journey of empowerment with our team of energy software development experts, who are dedicated to crafting advanced SCADA systems that harmoniously blend with demand-side response analysis (DSM) and energy management systems. The result? Enhanced transmission operations, cost efficiency, and an overall uplift in operational prowess. Revolutionizing Energy Sector Technology: The ELEKS Edge Consistent Power Delivery: Our SCADA systems provide the backbone for maintaining consistent and stable power delivery. Through meticulous monitoring and control, we ensure reliability that keeps the lights on and operations running smoothly. Optimized Costs: ELEKS' expertise extends to optimizing costs, creating solutions that not only meet energy demands but also enhance resource allocation, reducing unnecessary expenditure. Enabling Smart Grids: In an era where smart technologies dominate, our solutions lay the groundwork for seamless integration with smart grids, transforming your energy landscape into one of intelligence and adaptability. Advanced SCADA Systems: Our energy software development experts are primed to construct advanced SCADA systems that serve as the backbone of your operations, ensuring real-time data, control, and responsiveness. Demand-Side Response Analysis (DSM): Seamlessly integrate DSM to your SCADA framework, enabling you to respond dynamically to energy demand fluctuations, optimizing usage, and minimizing waste. Energy Management Systems: Elevate your energy management capabilities with systems designed to intelligently analyze, allocate, and optimize energy resources, fostering sustainability and efficiency. Enhanced Transmission Operations: ELEKS' solutions empower your transmission operations, minimizing downtime, enhancing system stability, and ultimately improving customer satisfaction. Future-Proof Solutions: Our focus on cutting-edge trends ensures that your energy infrastructure is ready to adapt to the technological evolution of the industry. Customization to Your Needs: We understand that each energy company has unique requirements. Our solutions are tailored to your specific needs, ensuring maximum efficiency and effectiveness. Operational Efficiency Amplified: From power delivery to cost management, our comprehensive approach ensures operational efficiency that drives your energy business forward. Experience Energy Excellence with ELEKS At ELEKS, we're not just about creating software – we're about catalyzing transformation. Our energy sector technology expertise converges with your goals, setting the stage for unparalleled growth, efficiency, and innovation. Join us in reshaping the future of energy and utilities, where SCADA systems, DSM, and energy management systems blend harmoniously to create an energy landscape that's not just efficient, but exceptional. ELEKS is your partner on the journey to a brighter, more sustainable energy future.

Service

Made to Order

Service

New

ISO

Storm Choke® K safety valves are ambient-type, wireline retrievable valves with the largest flow area of all direct controlled safety valves on the market. They are ideally suited for high-volume, low-pressure wells. These valves are normally closed and pre-charged with a set dome pressure. When the well flowing pressure drops below the predetermined dome-pressure charge because of a rupture in flowline or surface equipment, the dome pressure and main valve spring close the valve, shutting in the well below the earth’s surface. This valve contains a detent mechanism to provide a positive snap-action closure at the predetermined disaster rate of the valve. Its bore is not restricted by a flow bean. The valve is designed to resist pressure surges. A metal-to-metal poppet valve and seat comprise the valve’s primary closure mechanism. The K valve is ideal for protecting wells with declining bottomhole pressure. This valve closes in situations where a pressure decline would not activate a valve with a flow bean. To reopen the valve, the operator must fully equalize pressure either by applying pressure in the tubing from the surface or by an equalizing prong. The valve will reopen when the tubing pressure acting on the internal piston area overcomes the dome charge. Applications » Wells with declining bottomhole pressure » High-volume, low-pressure wells » Wells with no provisions for surface-controlled valves Features » Poppet closure » Large ports with capacity for high-volume wells » Designed to resist pressure surges *description excerpted from manufacturers catalogue.

Buy

Made to Order

Product

New

API

Sea Freight

Elevating Downhole Precision: HOCA Oil Tools B.V.'s Slickline Stem Solutions In the intricate arena of oil and gas extraction, downhole operations necessitate tools that promise not only precision but also unwavering reliability. HOCA Oil Tools B.V. takes pride in offering a sophisticated range of slickline stems that cater to a myriad of operational needs, ensuring unmatched performance and safety. Our expertise in crafting these essential tools is evident from the wide array of slickline stems available, designed to enhance the efficiency and safety of wireline operations. Benefits of Using HOCA's Slickline Stems: Enhanced Downhole Control: Our stems provide the necessary weight to ensure smooth and controlled movements of the tool string within the wellbore, enhancing operational precision. Versatility for Various Applications: From standard solid bars to specialized options like lead or tungsten filled, our range caters to different well conditions and requirements. Optimized Performance: The added weight helps counteract wellbore pressure, improving the impact and effectiveness of downhole tools, particularly in jarring operations. Increased Safety: Proper use of slickline stems reduces the risk of wireline snapping and other operational hazards, ensuring a safer environment for field personnel. Durability in Harsh Conditions: Manufactured with high-quality materials, our stems are designed to withstand the demanding conditions of downhole environments. Customization Options: Available in various sizes and materials, our stems can be tailored to meet the specific needs of each operation, ensuring maximum efficiency and effectiveness. Main Features of HOCA's Slickline Stems: Type ‘A’ Stem (Weight Bar): Offers solid bar configurations ideal for standard operations, providing necessary weight to the tool string with threaded connections for easy integration. Type ‘BO’ Lead Filled Stem: Incorporates lead within the stem to add substantial weight, ideal for deeper or more challenging well conditions, ensuring better control and impact. Type ‘EO’ Roller Stem: Features external rollers to minimize friction and wear during operations, enhancing the stem's longevity and performance in deviated wells. Type ‘ED’ Tungsten Filled Stem: Utilizes tungsten to provide maximum weight in a minimal space, perfect for high-pressure wells where additional downforce is required. Customization and Variety: Our stems are available in various lengths, diameters, and thread connections, ensuring compatibility with different tool strings and operational needs. HOCA Oil Tools B.V.'s commitment to quality and innovation is reflected in our slickline stem offerings. By providing a comprehensive range of sizes, materials, and types, we ensure that our clients have access to the tools necessary for their unique downhole challenges. Trust HOCA for your downhole tool needs, where precision meets durability.

Buy

In Stock

Product & Service

New

API

Air Freight