Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

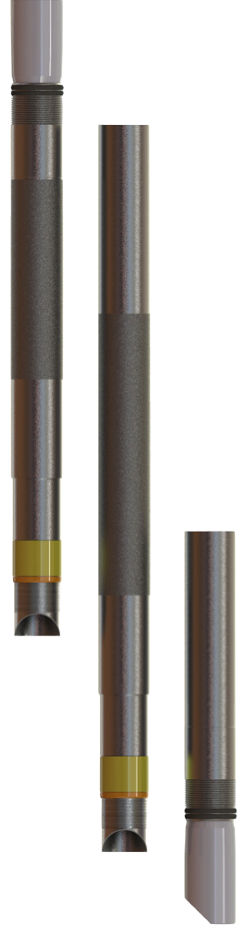

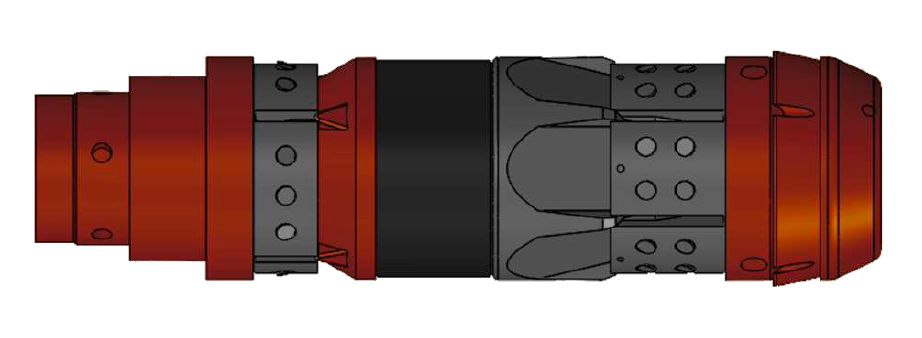

GTX-SPAN

Also known as:

Gas Tight Tubing Patch, Isolation SleeveBuy

In Stock

Product & Service

New

API

Sea Freight

Title:

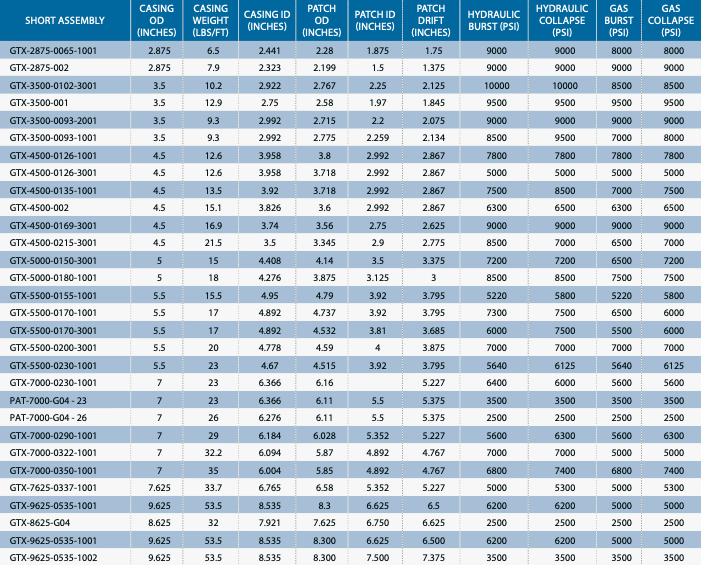

Gas Tight Casing Patch GTX-SPANModel Number:

GTX-SPANAvailability:

In StockDelivery Time (weeks):

3 weeksChoose

Transaction Type

BuyCondition

NewWeight

Varies lbsLocation

NetherlandsCompany Type

Product and Service ProviderQuality Assurance

APIPrice

Request for QuoteMaterial

SteelBrand Name

ID OiltoolsShipping

Land FreightNotes

The GTX-SPAN adds premium sealing elements with each element containing two elastomer seals that have enabled us to provide the industry with the first effective gas tight patch.

![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

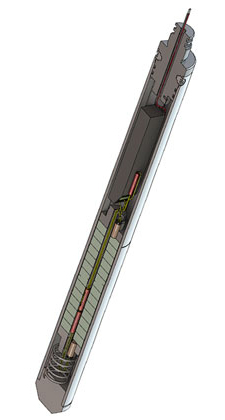

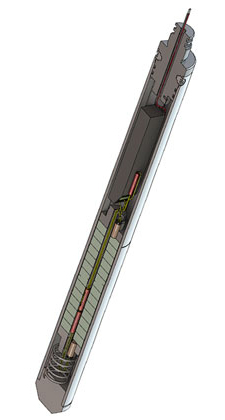

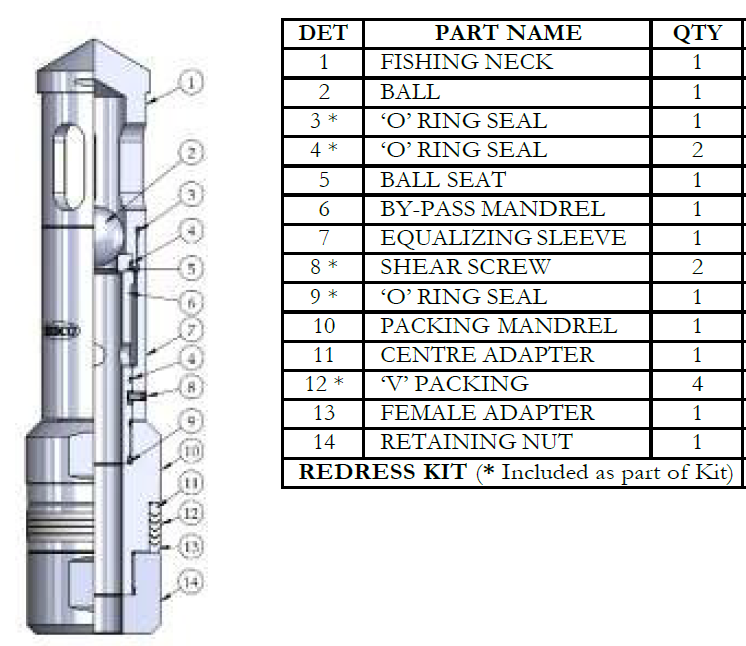

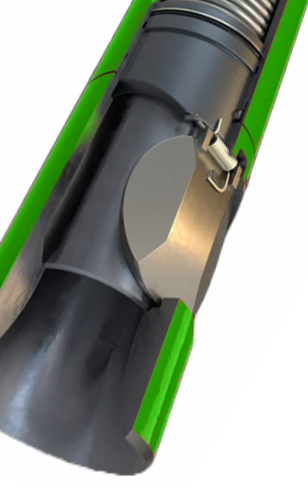

Introducing the V0 retrievable bridge plug from ID Oil Tools, the ultimate solution for temporary wellbore isolation, zonal isolation, and downhole check valves. The V0 plug can be deployed using slickline, e-line or coiled tubing, and can be set using conventional industry standard setting tools and associated interface connections. What sets the V0 plug apart from the rest is its ease of removal. Simply use a standard GS Pulling tool with prong to equalize and remove the plug. Plus, it has been tested and certified according to ISO14310 V0 (Gas tight) standards, ensuring its reliability and durability. The V0 plug also offers versatility with its elastomers that can work in temperatures up to 150°C. This makes it the perfect solution for suspending instrumentation such as pressure and temperature memory gauges. Choose the V0 retrievable bridge plug from ID Oil Tools for all your wellbore isolation and zonal isolation needs.

Buy

In Stock

Product

New

API

Sea Freight

![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing the revolutionary slim design composite plug from ID OILTOOLS – the "Long Range" Composite Frac Plug! With its advanced engineering, this plug is designed to pass through damaged casing, restricted internal casing diameters, and existing casing patches in the wellbore. Now, you can get more from every investment with this cost-effective option for both vertical and horizontal wells. The "Long Range" plug features a unique pump-down element design that requires less fluid and pump pressure to deploy the plug horizontally. It is made with better materials for better results, incorporating composite material and aluminum construction. This makes it possible for wells previously marked for abandonment to be re-completed, increasing overall production and profitability. Our composite frac plug can be configured as a Ball Drop or Bridge Plug, and it can be deployed on wireline or coiled tubing. Its dependable cast iron slips secure the plug in place, and the positive lock-up feature ensures lock-up of multiple plugs in a single wellbore. Plus, custom O.D. is available upon request. Don't miss out on this patented technology that has already proven its success. Choose ID OILTOOLS for the Long Range Composite Frac Plug and experience the next level of downhole solutions.

Buy

In Stock

Product

New

API

Sea Freight

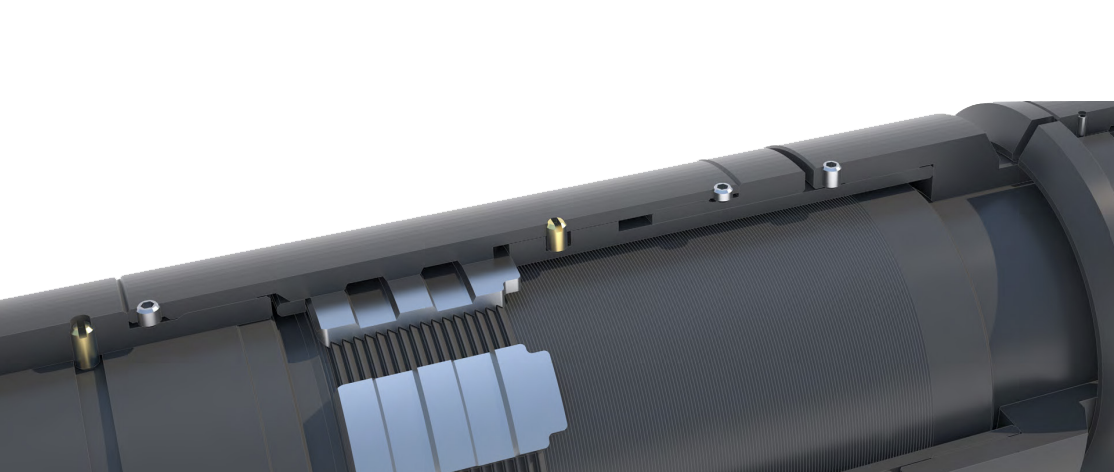

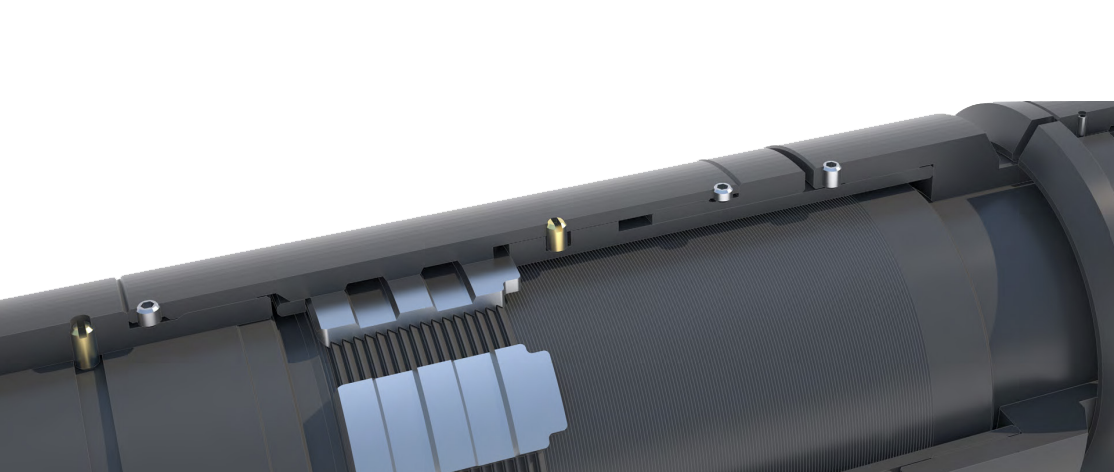

X-Span Casing Patch Deployment System

Casing Patch Setting Tool![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Deploying X-SPAN systems has never been easier! With a range of multi-stage explosive, electric line non-explosive or hydraulic setting tools available, our X-SPAN systems can be deployed quickly and efficiently in any well application. Our explosive setting tools can be initiated electrically, on e-line or slick line using a variety of compatible firing systems. For conventional tubing or coil tubing deployment requirements, several sizes of hydraulically operated setting tools are available to meet your specific needs. Our X-SPAN systems are not only easy to deploy, but they are also easy to remove. Simply mill off the sealing elements and your well is ready for the next application. We take pride in the reliability and quality of our X-SPAN systems, which have been proven many times with over 2900 successful installations completed with a 98% success rate when setting depth has been achieved. At ID OILTOOLS, we are committed to providing our customers with the highest quality and most reliable products on the market. Contact our Tech Services department today to learn more about our X-SPAN systems and how they can benefit your well application.

Buy

In Stock

Product & Service

New

API

Sea Freight

Tubing Cutter / Drill Pipe Cutter

Tubing Cutter![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing Tubing Cutter / Drill Pipe Cutters from ID Oiltools - the perfect solution to quickly and effectively sever tubing during the removal of stuck pipe. Our Tubing Cutters are designed to handle the toughest situations when tubing becomes stuck in the well. To achieve maximum performance, we recommend choosing the cutter with the largest possible diameter that can run in the well. Our Tubing Cutter / Drill Pipe Cutters are air shippable at Class 1.4D and conform to API RP-67, ensuring that you receive a reliable and safe product. To maximize the effectiveness of the tool, our cutters should be centralized and run in recommended applications. Don't let stuck tubing slow down your operations - trust ID Oiltools Tubing Cutter / Drill Pipe Cutters to provide a quick and efficient solution. Contact us today to learn more about how we can help you overcome the toughest challenges in your well operations.

Buy

In Stock

Product & Service

New

API

Sea Freight

![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing the Magna Range Bridge Plug from ID OilTools – the ultimate solution to passing restrictions and securely setting in larger tubing or casing. Our plug has been specially designed to handle differential pressures of up to 10,000psi at 350°F, making it the perfect choice for your downhole operations. Due to the extended setting range this plug has no pressure rating and as such the differential pressures are not guaranteed, even though the plug has passed several tests in these conditions. What sets our plug apart is its extended setting range, which allows it to pass through restricted I.D. tubing, saving you valuable time and money. With case-hardened slips above and below a three-piece nitrile rubber pack-off system, our plug is designed to maintain a constant sealing pressure. The slips are specially heat-treated to ensure a secure anchoring even in P-110 casing, with a hard outer layer for gripping and a soft inner layer for easier milling. To ensure centered setting of the small diameter plug in large I.D. pipe, our Magna Range Plug features ribbed cones that direct the slips to evenly spaced positions against the pipe. And should it be necessary to remove the plug after setting, a milling process is recommended as the plug is constructed of mild steel and is not considered drillable. Don't compromise on quality and reliability when it comes to your downhole operations. Choose the Magna Range Bridge Plug from ID OilTools, and experience the ultimate in performance and efficiency.

Buy

In Stock

Product

New

API

Sea Freight

![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing ID Oiltools' Drill Collar Severing Tools - the reliable and safe solution for Pipe Recovery Operations. Our Drill Collar Severing Tools utilize Explosive Bridge-Wires to simultaneously detonate columns, creating a shock wave collision that severs the tubular with precision. Our tool provides a quick and effective solution to sever heavyweight drill pipe and drill collars, and is designed to conform to API RP-67 for maximum safety. With air shippable detonators and hardware shipped separately, our Drill Collar Severing Tools are the ultimate in convenience and efficiency. Our patented Explosive Bridge-Wire Detonators increase the precision of the colliding shock-waves for maximum performance, making it the tool of choice for stuck pipe or plug and abandonment (P & A) operations. Choose the tool with the largest possible diameter capable of running in the stuck pipe for maximum results. Tension should be applied to the tubing prior to detonation of the Severing Tool to assist in the removal of stuck tubulars. Trust ID Oiltools to provide the safe, efficient, and reliable solution for all your Pipe Recovery Operations.

Buy

In Stock

Product & Service

New

API

Sea Freight

Tubing Cutter / Drill Pipe Cutter

Tubing Cutter![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing Tubing Cutter / Drill Pipe Cutters from ID Oiltools - the perfect solution to quickly and effectively sever tubing during the removal of stuck pipe. Our Tubing Cutters are designed to handle the toughest situations when tubing becomes stuck in the well. To achieve maximum performance, we recommend choosing the cutter with the largest possible diameter that can run in the well. Our Tubing Cutter / Drill Pipe Cutters are air shippable at Class 1.4D and conform to API RP-67, ensuring that you receive a reliable and safe product. To maximize the effectiveness of the tool, our cutters should be centralized and run in recommended applications. Don't let stuck tubing slow down your operations - trust ID Oiltools Tubing Cutter / Drill Pipe Cutters to provide a quick and efficient solution. Contact us today to learn more about how we can help you overcome the toughest challenges in your well operations.

Buy

In Stock

Product & Service

New

API

Sea Freight

Gas Tight Casing Patch GTX-SPAN

GTX-SPAN![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

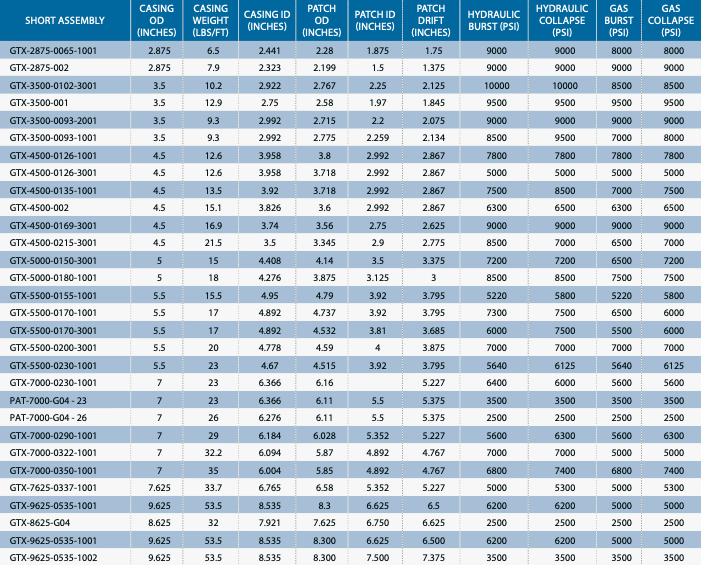

Looking for a heavy-duty, permanent solution for sealing splits, holes or perforations in your tubing and casing? Look no further than the GTX-SPAN System Tubing/Casing Patch from ID OILTOOLS! Our GTX-SPAN System is the first effective gas tight patch on the market, thanks to the premium sealing elements in each component. Each element contains two elastomer seals, providing superior gas shut off capabilities. The GTX-SPAN System is incredibly versatile, and can be run on electric wireline, tubing, or coil tubing, and set with a pressure setting tool (electrical, mechanical, or hydraulic). The large bores ensure easy passage of tools and equipment, minimizing restriction to fluid flow. Customizable for most well applications, including premium alloys, restrictions, and geothermal well applications, our GTX-SPAN System Tubing/Casing Patch is the solution you need for your sealing needs. Our system consists of three basic components: a top metal element with an expandable elastomer seal, a tubular extension, and a bottom metal element with an expandable elastomer seal. Various patch lengths can be obtained by adding tubular extensions, making it a modular and versatile solution for any well. During the setting process, the pressure setting tool exerts a pushing force on the top tapered metal swage and a pulling force on the bottom tapered metal swage. Both swages are driven into the metal sealing elements (with expandable elastomer seals), which expand outward into the casing wall, providing both a metal-to-metal and an elastomer seal. At a predetermined force, a calibrated weak point shears, and the setting process ceases. A collapsible setting collet located in the bottom swage retracts and allows the setting equipment to be retrieved. The interval is now fully isolated with metal and expandable elastomer seals. ID OILTOOLS highly recommends the use of a casing scraper before patch installation to rid the interval of foreign matter and the use of a casing caliper to provide an accurate record of casing I.D. and conditions. A gauge ring or drift run is a minimum requirement. Choose the GTX-SPAN System Tubing/Casing Patch from ID OILTOOLS for the first effective gas tight patch on the market. Contact us today to learn more!

Buy

In Stock

Product & Service

New

API

Sea Freight

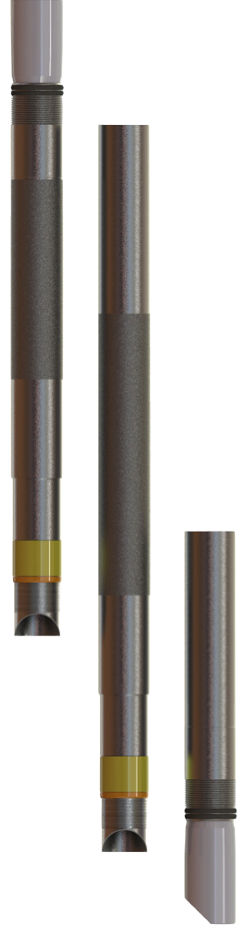

Casing Patch Stackable System - STX-SPAN

Stackable Casing Patch![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing the new multi-trip stackable STX-SPAN version from ID OILTOOLS! This cutting-edge system is the perfect solution for isolating longer intervals in flowing or static wells. With the ability to be deployed on wire line, slick line, coil tubing or conventional tubing, the STX-SPAN is versatile and can be used in a variety of applications. The STX-SPAN is also ideal for wells with limited rig up height and on wells that have severe dog legs where only short sections will pass. Each section seals to the previous one via a ratchet latch stinger and seal bore receptacle, making it easy to use and efficient. Our stackable X-SPAN products allow for long straddle systems to be deployed in multiple runs, making it perfect for when lubricator length or well accessibility is an issue. With the ability to isolate the top and bottom of the intended zone using X-SPAN or GTX-SPAN elements, this technology allows for extremely long isolation systems to be deployed. Additionally, specially engineered seal assemblies are utilized between each sequential intermediate section for added reliability. The STX-SPAN can incorporate standard off-the-shelf customer supplied tubulars as straddle base pipe material, and can incorporate sand screens, slotted liner, flow control devices such as profile nipples and sliding sleeves. It is also rated for high pressure and high temperature applications, making it perfect for a variety of environments. So, if you're looking for a versatile, reliable, and easy-to-use system for isolating longer intervals in your wells, look no further than the STX-SPAN from ID OILTOOLS! Contact our Tech Services department for assistance and more information on this game-changing product.

Buy

In Stock

Product & Service

New

API

Sea Freight

![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing the V0 retrievable bridge plug from ID Oil Tools, the ultimate solution for temporary wellbore isolation, zonal isolation, and downhole check valves. The V0 plug can be deployed using slickline, e-line or coiled tubing, and can be set using conventional industry standard setting tools and associated interface connections. What sets the V0 plug apart from the rest is its ease of removal. Simply use a standard GS Pulling tool with prong to equalize and remove the plug. Plus, it has been tested and certified according to ISO14310 V0 (Gas tight) standards, ensuring its reliability and durability. The V0 plug also offers versatility with its elastomers that can work in temperatures up to 150°C. This makes it the perfect solution for suspending instrumentation such as pressure and temperature memory gauges. Choose the V0 retrievable bridge plug from ID Oil Tools for all your wellbore isolation and zonal isolation needs.

Buy

In Stock

Product

New

API

Sea Freight

Casing Patch Stackable System - STX-SPAN

Stackable Casing Patch![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing the new multi-trip stackable STX-SPAN version from ID OILTOOLS! This cutting-edge system is the perfect solution for isolating longer intervals in flowing or static wells. With the ability to be deployed on wire line, slick line, coil tubing or conventional tubing, the STX-SPAN is versatile and can be used in a variety of applications. The STX-SPAN is also ideal for wells with limited rig up height and on wells that have severe dog legs where only short sections will pass. Each section seals to the previous one via a ratchet latch stinger and seal bore receptacle, making it easy to use and efficient. Our stackable X-SPAN products allow for long straddle systems to be deployed in multiple runs, making it perfect for when lubricator length or well accessibility is an issue. With the ability to isolate the top and bottom of the intended zone using X-SPAN or GTX-SPAN elements, this technology allows for extremely long isolation systems to be deployed. Additionally, specially engineered seal assemblies are utilized between each sequential intermediate section for added reliability. The STX-SPAN can incorporate standard off-the-shelf customer supplied tubulars as straddle base pipe material, and can incorporate sand screens, slotted liner, flow control devices such as profile nipples and sliding sleeves. It is also rated for high pressure and high temperature applications, making it perfect for a variety of environments. So, if you're looking for a versatile, reliable, and easy-to-use system for isolating longer intervals in your wells, look no further than the STX-SPAN from ID OILTOOLS! Contact our Tech Services department for assistance and more information on this game-changing product.

Buy

In Stock

Product & Service

New

API

Sea Freight

![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing ID Oiltools' Drill Collar Severing Tools - the reliable and safe solution for Pipe Recovery Operations. Our Drill Collar Severing Tools utilize Explosive Bridge-Wires to simultaneously detonate columns, creating a shock wave collision that severs the tubular with precision. Our tool provides a quick and effective solution to sever heavyweight drill pipe and drill collars, and is designed to conform to API RP-67 for maximum safety. With air shippable detonators and hardware shipped separately, our Drill Collar Severing Tools are the ultimate in convenience and efficiency. Our patented Explosive Bridge-Wire Detonators increase the precision of the colliding shock-waves for maximum performance, making it the tool of choice for stuck pipe or plug and abandonment (P & A) operations. Choose the tool with the largest possible diameter capable of running in the stuck pipe for maximum results. Tension should be applied to the tubing prior to detonation of the Severing Tool to assist in the removal of stuck tubulars. Trust ID Oiltools to provide the safe, efficient, and reliable solution for all your Pipe Recovery Operations.

Buy

In Stock

Product & Service

New

API

Sea Freight

Gas Tight Casing Patch GTX-SPAN

GTX-SPAN![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Looking for a heavy-duty, permanent solution for sealing splits, holes or perforations in your tubing and casing? Look no further than the GTX-SPAN System Tubing/Casing Patch from ID OILTOOLS! Our GTX-SPAN System is the first effective gas tight patch on the market, thanks to the premium sealing elements in each component. Each element contains two elastomer seals, providing superior gas shut off capabilities. The GTX-SPAN System is incredibly versatile, and can be run on electric wireline, tubing, or coil tubing, and set with a pressure setting tool (electrical, mechanical, or hydraulic). The large bores ensure easy passage of tools and equipment, minimizing restriction to fluid flow. Customizable for most well applications, including premium alloys, restrictions, and geothermal well applications, our GTX-SPAN System Tubing/Casing Patch is the solution you need for your sealing needs. Our system consists of three basic components: a top metal element with an expandable elastomer seal, a tubular extension, and a bottom metal element with an expandable elastomer seal. Various patch lengths can be obtained by adding tubular extensions, making it a modular and versatile solution for any well. During the setting process, the pressure setting tool exerts a pushing force on the top tapered metal swage and a pulling force on the bottom tapered metal swage. Both swages are driven into the metal sealing elements (with expandable elastomer seals), which expand outward into the casing wall, providing both a metal-to-metal and an elastomer seal. At a predetermined force, a calibrated weak point shears, and the setting process ceases. A collapsible setting collet located in the bottom swage retracts and allows the setting equipment to be retrieved. The interval is now fully isolated with metal and expandable elastomer seals. ID OILTOOLS highly recommends the use of a casing scraper before patch installation to rid the interval of foreign matter and the use of a casing caliper to provide an accurate record of casing I.D. and conditions. A gauge ring or drift run is a minimum requirement. Choose the GTX-SPAN System Tubing/Casing Patch from ID OILTOOLS for the first effective gas tight patch on the market. Contact us today to learn more!

Buy

In Stock

Product & Service

New

API

Sea Freight

Tubing Cutter / Drill Pipe Cutter

Tubing Cutter![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing Tubing Cutter / Drill Pipe Cutters from ID Oiltools - the perfect solution to quickly and effectively sever tubing during the removal of stuck pipe. Our Tubing Cutters are designed to handle the toughest situations when tubing becomes stuck in the well. To achieve maximum performance, we recommend choosing the cutter with the largest possible diameter that can run in the well. Our Tubing Cutter / Drill Pipe Cutters are air shippable at Class 1.4D and conform to API RP-67, ensuring that you receive a reliable and safe product. To maximize the effectiveness of the tool, our cutters should be centralized and run in recommended applications. Don't let stuck tubing slow down your operations - trust ID Oiltools Tubing Cutter / Drill Pipe Cutters to provide a quick and efficient solution. Contact us today to learn more about how we can help you overcome the toughest challenges in your well operations.

Buy

In Stock

Product & Service

New

API

Sea Freight

![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing the revolutionary slim design composite plug from ID OILTOOLS – the "Long Range" Composite Frac Plug! With its advanced engineering, this plug is designed to pass through damaged casing, restricted internal casing diameters, and existing casing patches in the wellbore. Now, you can get more from every investment with this cost-effective option for both vertical and horizontal wells. The "Long Range" plug features a unique pump-down element design that requires less fluid and pump pressure to deploy the plug horizontally. It is made with better materials for better results, incorporating composite material and aluminum construction. This makes it possible for wells previously marked for abandonment to be re-completed, increasing overall production and profitability. Our composite frac plug can be configured as a Ball Drop or Bridge Plug, and it can be deployed on wireline or coiled tubing. Its dependable cast iron slips secure the plug in place, and the positive lock-up feature ensures lock-up of multiple plugs in a single wellbore. Plus, custom O.D. is available upon request. Don't miss out on this patented technology that has already proven its success. Choose ID OILTOOLS for the Long Range Composite Frac Plug and experience the next level of downhole solutions.

Buy

In Stock

Product

New

API

Sea Freight

Looking for a heavy-duty, permanent solution for sealing splits, holes or perforations in your tubing and casing? Look no further than the GTX-SPAN System Tubing/Casing Patch from ID OILTOOLS! Our GTX-SPAN System is the first effective gas tight patch on the market, thanks to the premium sealing elements in each component. Each element contains two elastomer seals, providing superior gas shut off capabilities. The GTX-SPAN System is incredibly versatile, and can be run on electric wireline, tubing, or coil tubing, and set with a pressure setting tool (electrical, mechanical, or hydraulic). The large bores ensure easy passage of tools and equipment, minimizing restriction to fluid flow. Customizable for most well applications, including premium alloys, restrictions, and geothermal well applications, our GTX-SPAN System Tubing/Casing Patch is the solution you need for your sealing needs. Our system consists of three basic components: a top metal element with an expandable elastomer seal, a tubular extension, and a bottom metal element with an expandable elastomer seal. Various patch lengths can be obtained by adding tubular extensions, making it a modular and versatile solution for any well. During the setting process, the pressure setting tool exerts a pushing force on the top tapered metal swage and a pulling force on the bottom tapered metal swage. Both swages are driven into the metal sealing elements (with expandable elastomer seals), which expand outward into the casing wall, providing both a metal-to-metal and an elastomer seal. At a predetermined force, a calibrated weak point shears, and the setting process ceases. A collapsible setting collet located in the bottom swage retracts and allows the setting equipment to be retrieved. The interval is now fully isolated with metal and expandable elastomer seals. ID OILTOOLS highly recommends the use of a casing scraper before patch installation to rid the interval of foreign matter and the use of a casing caliper to provide an accurate record of casing I.D. and conditions. A gauge ring or drift run is a minimum requirement. Choose the GTX-SPAN System Tubing/Casing Patch from ID OILTOOLS for the first effective gas tight patch on the market. Contact us today to learn more!

Coiled Tubing Sliding Sleeve Activator

SSA Sliding SLeeve Actuator![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SSA (Sliding Sleeve Actuator) from Marlin Oil Tools: Revolutionizing Multistage Fracturing Operations Marlin Oil Tools proudly presents the SSA (Sliding Sleeve Actuator), a state-of-the-art downhole tool designed to optimize well intervention and multistage fracturing operations. Engineered to activate sliding sleeves with unparalleled efficiency and precision, the SSA is an essential tool for modern well completion strategies. By eliminating the need for traditional activation balls, the SSA streamlines fracturing operations, significantly reducing intervention times and enhancing overall well productivity. Key Features of the SSA (Sliding Sleeve Actuator): Efficient Sleeve Activation: The SSA is specifically designed to activate sliding sleeves in the liner of the well, targeting planned fracturing spots with accuracy. Simplifies Operations: Replaces the conventional method of dropping activation balls into the well, thereby simplifying the activation process. Rapid Deployment and Retrieval: Engineered for use with coil tubing, the SSA ensures quick deployment and retrieval, minimizing downtime in fracturing operations. Eliminates Milling or Catching: By using the SSA, the need to mill or catch activation balls post-fracturing is removed, enhancing operational safety and efficiency. Seamless Integration: Optimally designed to integrate with existing well completion setups, the SSA facilitates a smooth fracturing process. Precision in Fracturing: Offers precise control over the activation of sliding sleeves, ensuring effective multistage fracturing exactly where needed. Elevate your well intervention and fracturing operations with the SSA (Sliding Sleeve Actuator) from Marlin Oil Tools, a groundbreaking solution tailored for the oil and gas industry. This innovative downhole tool revolutionizes sliding sleeve activation during multistage fracturing, offering a more efficient and precise alternative to traditional activation balls. Designed for rapid deployment and retrieval via coil tubing, the SSA not only simplifies fracturing operations but also significantly enhances well productivity and safety. Choose the SSA for a streamlined, effective approach to modern well completions and fracturing. Why Choose the SSA from Marlin Oil Tools? Operational Efficiency: Dramatically reduces intervention times, allowing for faster and more efficient fracturing operations. Enhanced Safety and Simplicity: Removes the complexities and safety concerns associated with milling or catching traditional activation balls. Precision Activation: Ensures accurate activation of sliding sleeves, maximizing the effectiveness of multistage fracturing. Innovative Design: The SSA's design is optimized for ease of use with coil tubing, ensuring seamless operation and integration into fracturing workflows. The SSA (Sliding Sleeve Actuator) by Marlin Oil Tools represents the forefront of innovation in downhole tools, providing operators with an advanced solution to meet the challenges of today's fracturing operations. Incorporate the SSA into your well intervention toolkit to achieve superior efficiency, safety, and performance in multistage fracturing.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() OilHungry in Stoney Creek

OilHungry in Stoney Creek

The Oil-Only Absorbent Pillow, represented by the OH-PI1212, emerges as a utilitarian solution. From the versatile material known as polypropylene, this unassuming pillow bears the capacity to redefine the efficiency and sustainability of liquid cleanup. Why is Polypropylene chosen as the material for use? Polypropylene is a preferred material for oil-based cleanup for several reasons, making it an ideal choice for products like the Oil-Only Absorbent Pillow. Hydrophobic Nature Polypropylene is inherently hydrophobic, meaning it repels water. This characteristic is crucial in oil-based cleanup scenarios where the goal is to selectively absorb oils while avoiding the absorption of water. The hydrophobic nature of polypropylene ensures that the material remains focused on its primary task—absorbing oil-based liquids. High Affinity for Oil Polypropylene has a high affinity for oil-based substances. When in contact with oils, polypropylene quickly absorbs and retains these liquids. This property enhances the efficiency of cleanup operations, allowing for the rapid containment and absorption of oil spills. Lightweight and Durable Polypropylene is a lightweight yet durable material. This is advantageous in cleanup products like absorbent pillows, as it ensures ease of handling and deployment while maintaining structural integrity during use. The lightweight nature makes these products practical and user-friendly in various industrial settings. Chemical Resistance Polypropylene is known for its chemical resistance, providing stability when exposed to a wide range of substances, including oils and hydrocarbons. This resistance ensures that the material remains effective and does not break down when encountering various oil-based liquids. Recyclability Polypropylene is recyclable, adding an environmentally conscious aspect to its use in oil-based cleanup products. The ability to recycle polypropylene helps reduce the overall environmental impact by promoting the responsible disposal and reuse of materials. Cost-Effectiveness Polypropylene is a cost-effective material, contributing to the affordability of products designed for oil-based cleanup. Inert Nature Polypropylene is inert, meaning it does not react with or alter the composition of the substances it meets. This inert nature is crucial in cleanup situations where the goal is containment and absorption without introducing additional complications or reactions. Where is the Oil-Only Absorbent Pillow typically used? • Industrial facilities • Marine environment • Construction sites • Oil refineries • Emergency response • Environmental cleanup projects • Agricultural operations • Transportation Technical Specifications Part Number: OH-PI1212 Product Type: Absorbent Pillow Fluids Absorbed: Oil Based Liquids Volume Absorbed per unit: 1.35 gal Colour/Pattern: White Outside Skin Material: Polyester Rope Along Length: No Volume Absorbed per pkg.: 6.7 gal Floating: Yes UV Resistant: No Size: 12” x 12” Filler Material: Polypropylene Filler Sock/Boom Profile: Square Flame Resistant: No Incinerable: Yes

Buy

In Stock

Manufacturer

New

ASME

Air Freight

MS-32 Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. in New Delhi

Kessels Engineering Works Pvt. Ltd. in New Delhi

Unleash Unprecedented Power with the Kessels MS-102 Multistage Steam Turbine: The Apex of Efficiency and Reliability In the oil and gas industry, where power and precision are non-negotiable, Kessels Steam Turbines proudly presents the MS-102 Multistage Steam Turbine – a true marvel of engineering designed to redefine excellence in the world of steam turbines. Mastering Back-Pressure Turbines Back pressure turbines have long been the cornerstone of industrial steam applications, and our MS-102 Multistage Steam Turbine takes their capabilities to an entirely new level. Available in both single-stage and multi-stage configurations, these turbines are the linchpin between boiler units and process steam headers, revolutionizing steam utilization and power generation. Efficiency Beyond Compare At the heart of the MS-102 Multistage Steam Turbine lies the essence of back pressure turbines – the straight-back pressure design. This innovation ensures the seamless utilization of exhaust steam, aligning perfectly with process demands. Every unit of electrical power generated is consumed precisely as per the process steam demand, marking a new pinnacle of efficiency. Applications Without Boundaries Our MS-102 turbine is not merely a machine; it's a versatile powerhouse ready to excel in an array of applications: Drive Applications: Whether in the oil and gas sector, sugar mills, sugar fibrizor systems, shredder drives, pump drives, or beyond, our turbine delivers power where it's needed most. Power Generation Applications: Embrace sustainability by using our turbine to generate electricity, powering generators with clean and efficient steam energy while reducing your carbon footprint. Bleed Back-Pressure Steam Turbines At Kessels, we understand that adaptability is key. Our MS-102 turbine comes equipped with built-in bleed points, enabling uncontrolled extraction of steam within a medium pressure range. This feature is invaluable when low-volume steam demands and high tolerance for pressure variations are essential. Kessels turbines seamlessly combine the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines For industries with substantial process steam demand volumes and zero tolerance for pressure variations, our steam turbines with controlled extraction vents come to the forefront. Operating efficiently under intermediate pressure levels, these turbines ensure a consistent and reliable steam supply on which your operations can depend. Why Choose Kessels? Choosing Kessels Steam Turbines is more than a business decision; it's a commitment to a legacy of excellence, innovation, and reliability. Our MS-102 Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization while minimizing waste, resulting in cost savings and increased productivity. Reliability Beyond Question: Built with precision and rigorously tested to ensure uninterrupted operations, even in the most demanding environments. Unparalleled Versatility: Adapt effortlessly to changing needs, be it for drive applications or eco-friendly power generation, knowing that Kessels has you covered. A Sustainable Tomorrow: Harness the power of steam for electricity generation, reduce your environmental impact, and contribute to a greener future. Expert Support: Our team of specialists is at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive world of the oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-102 Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you toward a future of unprecedented success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

MS-42 EB Multistage Steam Turbine

Back Pressure Turbine![]() Kessels Engineering Works Pvt. Ltd. in New Delhi

Kessels Engineering Works Pvt. Ltd. in New Delhi

Unleash Power and Precision with the Kessels MS-42 EB Multistage Steam Turbine: Your Ultimate Back-Pressure Solution In the high-stakes world of the oil and gas industry, precision and performance are non-negotiable. That's why, at Kessels Steam Turbines, we're proud to introduce our cutting-edge MS-42 EB Multistage Steam Turbine – a powerhouse engineered to redefine excellence in back-pressure turbine technology. Mastering Back-Pressure Turbines Back pressure turbines have been the workhorses of industrial steam applications for decades, and our MS-42 EB takes their capabilities to new heights. Whether it's single-stage or multi-stage options, these turbines serve as the critical bridge between the boiler unit and the process steam header, revolutionizing steam utilization and power generation. Efficiency Redefined Our MS-42 EB Multistage Steam Turbine boasts the hallmark of back pressure turbines: their straight-back pressure nature. This design ensures the efficient harnessing of exhaust steam, meeting process demands with unparalleled precision. Every ounce of electrical power generated is consumed as per the process steam demand, offering unmatched efficiency. Applications Beyond Boundaries At Kessels, we understand that diverse industries have unique demands. That's why our MS-42 EB Multistage Steam Turbine excels in a wide range of applications: Drive Applications: Embrace the power of our turbine in oil and gas operations, sugar mills, sugar fibrizor systems, shredder drives, pump drives, and more. Wherever drive power is needed, Kessels delivers. Power Generation Applications: Elevate your sustainability game by using our turbine to generate electricity, powering generators with clean and efficient steam energy. Bleed Back-Pressure Steam Turbines Our commitment to versatility is evident in the design of the MS-42 EB. With built-in bleed points, uncontrolled extraction vents enable steam extraction within a medium pressure range. This feature proves invaluable in situations where bleeding steam is required at low volume steam demands and when there's a high tolerance for pressure variations. Kessels turbines seamlessly blend the best of both bleed and back-pressure mechanisms. Extraction Back-Pressure Steam Turbines When your process steam demand volume is substantial, and you can't compromise on pressure variations, our steam turbines with controlled extraction vents come to the rescue. These turbines operate under intermediate pressure levels, ensuring a steady and reliable steam supply that your operations can depend on. Why Choose Kessels? Choosing Kessels Steam Turbines means choosing a legacy of excellence, innovation, and reliability. Our MS-42 EB Multistage Steam Turbine is the embodiment of these principles, offering you: Unmatched Efficiency: Maximize steam utilization and minimize wastage with our precision-engineered turbine. Reliability Redefined: Rigorously tested and built with unwavering precision, the MS-42 EB ensures your operations run seamlessly. Unparalleled Versatility: Adapt to changing needs effortlessly, whether it's drive applications or eco-friendly power generation. Sustainability at Its Core: Harness the power of steam for electricity generation, reducing your carbon footprint and contributing to a greener future. Expert Support: Our team of specialists is always at your service, ready to assist with installation, maintenance, and troubleshooting. Empower Your Future with Kessels In the fiercely competitive oil and gas industry, every advantage matters. Step into a future of efficiency, reliability, and sustainability with the Kessels MS-42 EB Multistage Steam Turbine. Contact us today to discover how our turbine can revolutionize your operations and lead you towards a future of success. Kessels Steam Turbines – Powering Progress, Powering You.

Buy

Made to Order

Manufacturer

New

ISO

Air Freight

![]() Canaweld Inc. in Vaughan

Canaweld Inc. in Vaughan

Introducing the Canaweld Welder Cart for Single Phase Machines - Your Ultimate Welding Companion! When it comes to welding, having the right equipment at your fingertips is essential. That's why we've designed the Canaweld Welder Cart - a sturdy and reliable cart that will keep your single-phase machines organized and accessible at all times. With its thoughtful features and robust construction, this cart is the perfect addition to your welding setup. Built for Strength and Durability: The Canaweld Welder Cart is crafted with a strong steel construction that ensures it can handle the demands of the oil and gas industry. Its powder coat finish adds an extra layer of protection, making it resistant to wear and tear from daily use. Rest assured, this cart is built to last. Maximum Convenience, Minimum Effort: Moving your welding equipment has never been easier. The front caster wheels on our cart swivel a full 360 degrees, allowing for smooth and effortless turning. No more struggling to maneuver your machines - our cart does the work for you. Ample Storage Space: Organize your welding essentials with ease. The Canaweld Welder Cart features three-tier shelves thoughtfully designed to accommodate all your portable MIG welders, stick welders, plasma cutters, and necessary accessories. Plus, there's enough room for consumables and a gas cylinder, ensuring you have everything you need at your fingertips. Secure Your Equipment: Your safety is our priority. That's why we've equipped the cart with a chain to secure the gas tank firmly in place. Worried about keeping your cables and helmet tidy? The side hook provides a convenient storage solution for them, eliminating clutter and potential hazards. Unbeatable Dimensions: The Canaweld Welder Cart boasts spacious shelf dimensions that perfectly cater to your welding equipment: • Top Shelf: 18 X 11 X 1 inches • Middle Shelf: 15.5 X 11 X 1 inches • Lower Tray: 27.7 X 11.5 X 2 inches • Gas Bottle Space: 10.2 X 11.4 X 2 inches Ultimate Load Capacity: Our cart can handle the weight. With a load capacity of 110 lbs. (50 kg), you can trust that your valuable equipment is safe and secure while on the move. Efficiency Meets Style: The Canaweld Welder Cart is more than just a functional tool - it's a sleek and stylish addition to your welding setup. Its design not only optimizes your workflow but also adds a touch of professionalism to your workspace. Upgrade Your Welding Experience: Say goodbye to the hassle of transporting your welding equipment and embrace the convenience of the Canaweld Welder Cart. It's time to work smarter, not harder. Elevate your welding experience today with Canaweld - your trusted partner in welding solutions.

Buy

In Stock

Manufacturer

New

ASME

Land Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

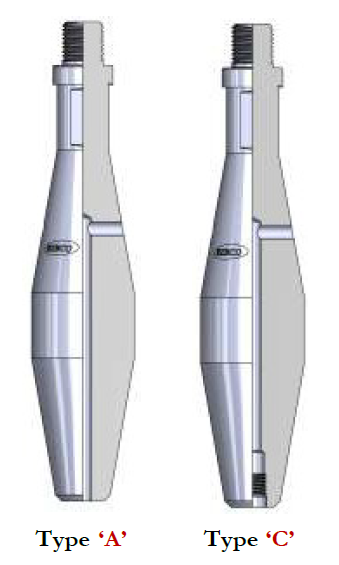

Unlock Efficiency in Oilfield Operations with HOCA Oil Tools’ Tubing Swages In the dynamic world of oilfield services, precision and reliability are non-negotiable. At HOCA Oil Tools, we understand the critical nature of downhole operations. That’s why we're proud to present our premium Tubing Swages – Type A and Type C – designed to meet and exceed the challenging demands of downhole slick line tools applications. Revolutionize Downhole Challenges with Tubing Swages Our Tubing Swages are engineered for excellence, ensuring your downhole operations are seamless and efficient. The Type A and Type C Tubing Swages are crafted with the highest quality materials, ensuring durability and long-lasting performance in the harshest environments. Type A Tubing Swage: This variant is meticulously designed to re-expand constricted tubing, ensuring a free passage for wireline tools and sub-surface controls. Its tapered ends facilitate easy navigation through tubing, while the central hole and lateral ports allow fluid bypass, optimizing performance. Type C Tubing Swage: Building on the features of Type A, the Type C Tubing Swage includes an additional box connection at the bottom, enhancing its functionality and application range. This feature ensures greater versatility, meeting diverse operational needs with ease. Six Benefits of Using HOCA’s Tubing Swages: Enhanced Productivity: By rectifying constrictions in the tubing, our swages ensure smooth operations, significantly reducing downtime and boosting productivity. Versatility: Available in various sizes, the Tubing Swages cater to a wide range of tubing diameters, ensuring the right fit for your specific operational needs. Durability: Crafted with high-quality materials, our swages withstand the challenging downhole environment, offering long-term reliability and reducing the need for frequent replacements. Efficient Design: The tapered design and fluid bypass capability ensure minimal resistance during operations, enhancing efficiency and effectiveness. Cost-Effective: By maintaining the integrity of your downhole tools and minimizing operational delays, our Tubing Swages prove to be a cost-effective solution in the long run. Safety: Designed with safety in mind, our swages help prevent accidents and equipment damage, ensuring a safer working environment. Transform Your Operations with HOCA Oil Tools At HOCA Oil Tools, we're committed to providing solutions that drive success. Our Tubing Swages are a testament to our commitment to quality, efficiency, and safety. Embrace the change with HOCA’s Tubing Swages and experience unparalleled downhole operational excellence.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Unlock Enhanced Efficiency and Safety with HOCA Oil Tools' Tubing Mandrel Running Tools In the challenging arena of oil and gas extraction, the significance of reliable, efficient, and precise tools is undeniable. HOCA Oil Tools, renowned for its commitment to innovation and quality, introduces its Tubing Mandrel Running Tools, designed to streamline and secure downhole operations. Our products stand as a testament to our dedication to advancing the oilfield industry's capabilities, offering unparalleled solutions to common downhole challenges. HOCA’s Tubing Mandrel Running Tools: Precision Engineered for Superior Performance HOCA Oil Tools’ Tubing Mandrel Running Tools are meticulously crafted to ensure the safe, efficient, and precise deployment of tubing mandrels within the wellbore. These tools are vital for maintaining the integrity and functionality of the tubing string, playing a crucial role in various downhole operations from completion to intervention. Built from high-grade materials and engineered to withstand demanding downhole conditions, our Tubing Mandrel Running Tools represent the pinnacle of downhole innovation. Experience the HOCA Oil Tools Advantage At HOCA Oil Tools, we understand the complexities of downhole operations and the importance of reliable tools in achieving successful outcomes. Our Tubing Mandrel Running Tools are a reflection of this understanding, offering solutions that enhance efficiency, safety, and cost-effectiveness. Incorporating our Tubing Mandrel Running Tools into your downhole operations not only signifies a commitment to operational excellence but also aligns your projects with the industry's highest standards. With HOCA Oil Tools, you gain more than just a supplier; you gain a dedicated partner committed to your success. Choose HOCA Oil Tools for your Tubing Mandrel Running Tools and experience the difference that quality, innovation, and dedicated support can make in your downhole operations. Elevate your wellbore activities with HOCA Oil Tools – where technology meets tradition in the pursuit of downhole excellence.

Buy

In Stock

Product & Service

New

API

Air Freight

M-KWIK Control Line and Cable Protector

Mid Joint Protector![]() Sivam S.p.A. in Spoltore

Sivam S.p.A. in Spoltore

Cross coupling protectors are essential tools used in the oil and gas industry during the installation of completions in oil and gas wells. These protectors provide a variety of benefits that make them a necessary investment for any oil and gas company. Protects Control Lines: Cross coupling protectors help protect control lines from damage that can be caused by the installation process, environmental factors, and other external factors. By providing an extra layer of protection, the control line can last longer and reduce the need for costly repairs or replacements. Prevents Fluid Contamination in Cables: Cross coupling protectors prevent fluid contamination by keeping debris and other unwanted materials out of electrical cables during installation. This is particularly important in the oil and gas industry where contamination can lead to significant safety risks, equipment damage, and production losses. Reduces Maintenance Costs: The installation of cross coupling protectors can help reduce maintenance costs. By protecting control lines and cables the completion is less likely to require maintenance or repair. This can result in significant cost savings over the long-term. Improves Efficiency: Cross coupling protectors help to improve the efficiency of the installation process. By providing a secure connection and preventing contamination, the installation process can be completed more quickly and with fewer re-work. This can help to reduce downtime and increase productivity. Enhances Safety: Cross coupling protectors enhance safety by reducing the risk of equipment failure and fluid contamination. This can help to prevent accidents and injuries, and ensure that the installation process is completed safely. The use of cross coupling protectors is critical to the successful installation of tubing in oil wells. They provide numerous benefits including protecting tubing joints, preventing fluid contamination, reducing maintenance costs, improving efficiency, and enhancing safety. By investing in cross coupling protectors, oil and gas operators can ensure the long-term success of their operations while improving their bottom line.

Buy

In Stock

New

New

API

Air Freight

![]() Lovat Gas Solutions in Edmonton

Lovat Gas Solutions in Edmonton

Tailor-Made Gas Solutions: Your Trusted Partner for Mobile Gas At Lovat Gas Solutions, we understand that every gas-related application is unique. That's why we leverage our extensive experience and expertise to develop tailor-made solutions that perfectly match your specific needs. Whether it's volume, application, duration, or location, we consider all the relevant factors to deliver the best solution for your job. What sets Lovat Gas Solutions apart? 1. Experience and Expertise: With years of industry experience, our team has a deep understanding of gas-related challenges and requirements. We have successfully designed and executed numerous projects across various sectors, earning the trust and loyalty of our customers. 2. Customized Approach: We believe in the power of customization. By considering your specific requirements, we develop fit-for-purpose solutions that precisely address your needs. Our solutions are not one-size-fits-all; they are carefully tailored to ensure optimal performance and efficiency for your application. 3. Quality Solutions: Our commitment to quality is unwavering. We take pride in delivering solutions that meet the highest standards of performance, safety, and reliability. When you choose Lovat Gas Solutions, you can trust that our fit-for-purpose solutions will exceed your expectations and deliver exceptional results. 4. Customer Satisfaction: Your satisfaction is our ultimate goal. We prioritize open communication and collaboration to ensure that we fully understand your objectives and challenges. Our dedicated team goes the extra mile to provide personalized service and support, making us the first call for our customers whenever they need mobile gas solutions. Contact Lovat Gas Solutions today and discover how we can help you with your mobile gas needs. We are confident that our tailor-made solutions will exceed your expectations, and one job is all it takes for you to experience the excellence of Lovat Gas Solutions. Let us be your trusted partner in delivering exceptional gas solutions that drive the success of your operations. Together, we will find the perfect fit for your gas requirements with Lovat Gas Solutions.

Service

Made to Order

Service

New

ISO

Land Freight

4-1/2 inch SP SCSSSV Tubing Retrievable

SCSSSV SP![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie

The SP™ tubing-retrievable safety valve (TRSV) is a single rod-piston non-elastomer flapper valve designed for hostile environments and extended life applications where ultimate reliability is required. Potential leak paths within the valve are minimized with the single rod-piston design. The piston achieves a metal-to-metal (MTM) seal at its uppermost and lowermost positions to seal well pressure from the control system. The SP valves incorporate flappers using spherical radius sealing surfaces that help greatly improve seal reliability. The spherical radius design provides full MTM sealing integrity. For applications where either the OD or ID is restrained, SP valves incorporate a contoured flapper. OD/ID relationships are improved by the contoured flapper design, which helps provide superior MTM sealing when compared to other forms of curved flapper technology. Applications » For applications requiring ultimate reliability and longevity, such as high-temperature/high-pressure, and subsea completions, or hostile well environments Features » Non-elastomer dynamic piston seals » MTM static seal at upper and lower piston positions » MTM body joints » Flow tube fluted guide » 100% MTM flapper » Concentric thrust bearing » Wiper ring on upper flow tube » Cleanout ports in flow tube’s upper end » Internal exercise profile » Flow tube shock absorber » MTM face seat at flow tube downstop » Setting depths to 9,000 ft (2743 m) » Critical components isolated from well debris with valve in open position » Area above flow tube free of solids buildup » Flow tube can be manipulated by slickline » Protected from high flow rate slam closures *information referenced from supplier catalog.

Buy

Made to Order

Product

New

API

Air Freight

![]() Sivam S.p.A. in Spoltore

Sivam S.p.A. in Spoltore

Half moon sheaves are designed to be used in conjunction with Sivam spooling units. Spooling units designed to ensure cables or control lines are kept in tension while running in or out of hole. Our spooling units are fully designed, manufactured and assembled with sheaves (half or full moon) to guide control, injection, or mono-conductor cable preventing damage while being tripped in hole. Units are available in pneumatic, hydraulic, or electric drive and are ATEX zone and DNV certified as required by location. Spooling units can also be equipped with a filling pump to monitor pressure while tripping – improving efficiency as a sudden pressure drop indicates line damage.

Buy

In Stock

New

New

ISO

Air Freight

![]() Eleks in Toronto

Eleks in Toronto

ELEKS: Your Ultimate Nearshore Software Development Partner Unlock the potential of nearshore software development with ELEKS – your gateway to building top-tier technology solutions across borders. With 11 delivery centers spanning 8 countries, we offer you a seamless collaboration experience that transcends geographical barriers and propels your projects to new heights. ELEKS Nearshore Software Development: The Future of Collaboration Time Zone and Geographical Alignment: Experience a level of synchronicity that offshore development can't provide. ELEKS nearshore software development ensures smooth communication, collaboration, and project delivery. Our nearshore advantage means regular onsite visits and a working partnership that's as cohesive as it is efficient. Unified Cultural Approach: Integration goes beyond technology – it's about embracing culture. Our experts seamlessly blend with your in-house team, adopting your unique ethos. Beyond that, we transfer vital process and behavior-change knowledge, ensuring a truly unified and synergistic approach. Faster Product Launch: Elevate your go-to-market strategy with ELEKS as your nearshore development partner. Our streamlined processes and collaborative approach mean you can launch your product twice as fast. Time is of the essence in today's dynamic market – we help you seize it. Superior Quality of Work: Satisfaction is not a target; it's a standard. At ELEKS, we never rest until you're completely satisfied. Our unmatched client satisfaction rating of 97% speaks volumes about our commitment to excellence. Trust us to deliver top-notch results. Access to Top Talent: ELEKS' talent pool boasts 2000+ multi-skilled specialists rooted in math and physics. This means you can assemble the perfect team to bring your vision to life. The right talent is the foundation of success – with us, it's a given. Dedicated Team: Complexity meets capability with our dedicated teams. We handpick specialists with tailored skills to flawlessly execute your software vision. No matter how intricate your project, our experts are up to the task. ELEKS Global Presence: Spanning 18 locations across three continents, ELEKS ensures swift and streamlined communication. With us, you'll experience the efficiency and cost-saving benefits of offshore development coupled with accessible, onsite collaboration. ELEKS Nearshore Software Development: Where Innovation Meets Excellence Our Nearshore Software Development Services: Our portfolio is a testament to three decades of innovation and expertise. With a wide range of market-leading software and consultancy services, we cater to global clients with diverse needs. What Sets ELEKS Apart? • Nearly three decades of custom software development excellence • Extensive technology consulting prowess • Deep strategic product design proficiency with a UX-certified team • One of Ukraine's largest data science teams • Mitigate investment risk with MVP development • Trailblazing technological innovation through our in-house R&D lab Nearshore vs. Offshore vs. Onshore: A Winning Formula with ELEKS When scaling or upskilling is the name of the game, onshore development can be effective but pricey. Offshore options save you time and money, but often come with control trade-offs. ELEKS introduces the winning formula: nearshore development. It blends cost efficiency with quality, offering streamlined communication and onsite visits without compromising savings. ELEKS Nearshore Software Development: Your Bridge to Innovation Experience the best of both worlds – a nearshore team that combines accessibility with efficiency. ELEKS empowers you to transcend borders, embrace innovation, and redefine success. With us, your nearshore journey is a step towards a more collaborative and prosperous future.

Service

In Stock

Service

New

ISO

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Maximize Well Integrity and Safety with HOCA Oil Tools' BHP Tool Accessories In the complex and demanding realm of oil and gas extraction, ensuring well integrity and optimizing production are paramount. HOCA Oil Tools rises to this challenge with our premium BHP (Bottom Hole Pressure) Tool Accessories, specifically designed to enhance the performance and reliability of downhole pressure monitoring systems. These accessories, vital for the precise measurement and control of well conditions, are engineered to complement our BHP tools, facilitating accurate data acquisition and ensuring well safety. HOCA’s BHP Tool Accessories: Elevating Downhole Precision and Reliability Our BHP Tool Accessories range includes various components crucial for the efficient operation of bottom-hole pressure tools. From specialized adaptors that ensure secure fittings to protective carriers designed to safeguard sensitive instruments during deployment and retrieval, each accessory is crafted to meet the highest standards of quality and performance. By addressing the unique challenges of downhole environments, HOCA Oil Tools provides the oil and gas industry with solutions that not only meet but exceed operational demands. Experience the Difference with HOCA Oil Tools Opting for HOCA Oil Tools' BHP Tool Accessories means choosing a partner dedicated to enhancing the efficiency and safety of your downhole operations. Our commitment to innovation and quality ensures that our products not only meet industry standards but also provide the reliability and performance essential for today's challenging oilfield environments. By integrating our BHP Tool Accessories into your operations, you are not only optimizing your downhole monitoring capabilities but also investing in the safety and longevity of your equipment. With HOCA Oil Tools, you gain access to a comprehensive suite of solutions designed to elevate your operational success. Choose HOCA Oil Tools for your BHP Tool Accessories and join the ranks of industry professionals who trust our products to enhance their downhole operations. Partner with us, and unlock the full potential of your oil and gas extraction activities with tools and accessories crafted for excellence. With HOCA Oil Tools, empower your downhole operations with precision-engineered solutions that deliver unmatched performance and reliability.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

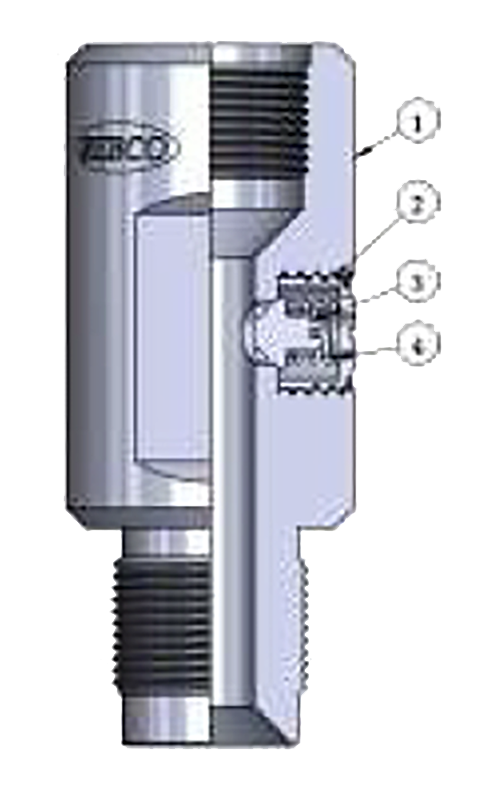

HOCA Oil Tools: Innovating Efficiency with State-of-the-Art Equalizing Subs In the ever-evolving landscape of the oil and gas industry, the need for precision and efficiency in downhole operations is paramount. At HOCA Oil Tools, we recognize this imperative and respond with our innovative Equalizing Subs. These tools are specifically designed to enhance the operational capabilities of sub-surface controls like Locking Mandrels and Tubing Mandrels, ensuring seamless and efficient downhole activities. HOCA’s Equalizing Subs: Engineered for Unmatched Performance Our Equalizing Subs are crafted to facilitate the equalization of pressure differentials across Sub-Surface Controls, crucial for the safe and effective retrieval of these components. Available in various types, including 'ROTB', 'ROTF', 'ROTC', 'ROTD', and others, each is designed to meet distinct downhole conditions and operational needs, ensuring versatility across different well environments. Experience the HOCA Oil Tools Difference Choosing HOCA Oil Tools' Equalizing Subs means selecting a solution backed by innovation, quality, and unwavering support. Our commitment to excellence ensures that our products not only meet but exceed the stringent demands of the oil and gas industry. Whether addressing standard operations or facing unique downhole challenges, our Equalizing Subs provide the reliability and performance essential for today's downhole activities. Incorporating our Equalizing Subs into your operational toolkit is a step towards enhanced efficiency, safety, and success. With HOCA Oil Tools, you gain more than just a supplier; you gain a partner dedicated to supporting your downhole challenges with cutting-edge solutions and comprehensive service. Opt for HOCA Oil Tools for your downhole needs and unlock the full potential of your operations. Partner with us to harness the power of advanced downhole solutions designed for the modern oilfield landscape. With HOCA Oil Tools, empower your downhole operations with tools that redefine efficiency, reliability, and performance in the oil and gas industry.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() Canaweld Inc. in Vaughan

Canaweld Inc. in Vaughan

Introducing the Canaweld CAD 81 Capacitor Discharge Stud Welding System: Power and Precision Unleashed! When it comes to high-performance stud welding, the Canaweld CAD 81 stands in a league of its own. Harnessing the cutting-edge technology of Capacitor Discharge (CD) stud welding, this welding system offers unparalleled precision, speed, and efficiency, making it the ultimate choice for welders in the oil and gas industry. Precision in a Blink - Capacitor Discharge Stud Welding The Canaweld CAD 81 utilizes a direct-current arc from a capacitor, allowing for weld times as quick as 1 to 6 milliseconds. The result? Seamlessly welded studs with no burn-through on the opposite side, even with very thin metals. Perfect for smaller diameter studs, pins, non-standard materials, and when precision is paramount. Compact Yet Powerful - Unmatched Welding Capacity Don't be fooled by its compact design; the Canaweld CAD 81 boasts a full 5/16-inch (M8) welding capacity, making it the most compact and versatile system on the market. Its microprocessor control ensures precise and consistent welding performance, while the enhanced charging circuit with a high output transformer maximizes its duty cycle, offering you unmatched welding power in a lightweight package. Safety and Ease of Use - User-Friendly and Efficient The Canaweld CAD 81 is designed with your safety and convenience in mind. With enhanced user feedback, including safety and fault codes, you can weld with confidence and peace of mind. The system comes complete with everything you need, including the gun, two ground cables, collets, changing tools, and a convenient carrying case for easy transportation. Features That Make a Difference Let's take a look at some of the remarkable features of the Canaweld CAD 81: • Weld Range: Accommodates US Stud Size #4 – 5/16”, Metric Stud Size (M3-M8), Stud diameter 0.112″ – 0.312″ • Input Power 1~115/230, 50/60Hz (internally switchable) • 81,000uf Capacitance for rapid and powerful welds • Portable and Lightweight: Weighing only 25 lbs., take it anywhere the job demands • Ergonomic Design: Designed for comfort and ease of use during extended welding sessions • Heavy-Duty Cable Set: Ensures robust and reliable connections • Dual Ground Cable: For added safety and efficiency • Fully Adjustable Leg Set: Achieve the perfect welding angle for every job • Diagnostic LEDs: Easy troubleshooting and maintenance The Canaweld CAD 81 - Empowering Welders in the Oil and Gas Industry At Canaweld, we take pride in providing cutting-edge welding machines and accessories that meet the unique demands of the oil and gas industry. The CAD 81 exemplifies our commitment to excellence, innovation, and your welding success. Unleash the Power of Precision and Performance with the Canaweld CAD 81 Capacitor Discharge Stud Welding System. Empower your welding journey with Canaweld - Your Partner in Welding Excellence!

Buy

In Stock

Manufacturer

New

ASME

Land Freight

Message:

To: supplier

![]() ID OILTOOLS B.V. in Oudkarspel

ID OILTOOLS B.V. in Oudkarspel

Introducing the revolutionary slim design composite plug from ID OILTOOLS – the "Long Range" Composite Frac Plug! With its advanced engineering, this plug is designed to pass through damaged casing, restricted internal casing diameters, and existing casing patches in the wellbore. Now, you can get more from every investment with this cost-effective option for both vertical and horizontal wells. The "Long Range" plug features a unique pump-down element design that requires less fluid and pump pressure to deploy the plug horizontally. It is made with better materials for better results, incorporating composite material and aluminum construction. This makes it possible for wells previously marked for abandonment to be re-completed, increasing overall production and profitability. Our composite frac plug can be configured as a Ball Drop or Bridge Plug, and it can be deployed on wireline or coiled tubing. Its dependable cast iron slips secure the plug in place, and the positive lock-up feature ensures lock-up of multiple plugs in a single wellbore. Plus, custom O.D. is available upon request. Don't miss out on this patented technology that has already proven its success. Choose ID OILTOOLS for the Long Range Composite Frac Plug and experience the next level of downhole solutions.

Buy

In Stock

Product

New

API

Sea Freight

![]() Hoca Oil Tools in Zwartemeer

Hoca Oil Tools in Zwartemeer

Elevate Downhole Diagnostics with HOCA Oil Tools' Lead Impression Blocks In the intricate world of downhole operations, understanding the precise conditions within the wellbore is not just beneficial—it's imperative. At HOCA Oil Tools, we specialize in providing top-tier downhole slick line tools that cater to the diverse needs of the oil and gas industry. A standout in our product lineup is the Lead Impression Block (LIB), an indispensable tool designed for capturing clear, detailed impressions of downhole conditions. Lead Impression Blocks: The Key to Accurate Downhole Intelligence HOCA's Lead Impression Blocks are engineered for exceptional performance, providing operators with the critical data needed to make informed decisions. Made with high-quality materials, our LIBs are designed to withstand the challenging environments found within wellbores, ensuring reliable results every time. Six Benefits of Using HOCA's Lead Impression Blocks: Precision Diagnostics: Our LIBs provide precise imprints of the downhole environment, enabling accurate identification of obstructions, tool fishings, and the condition of the wellbore. Cost-Efficiency: By delivering accurate downhole data, our LIBs help avoid unnecessary operations and reduce the risk of costly mistakes, leading to more efficient and cost-effective well management. Easy Interpretation: The clear impressions made by our LIBs allow for straightforward analysis, enabling quick decision-making and streamlined operations. Durability and Reliability: Designed for the rugged downhole environment, HOCA's Lead Impression Blocks are built to last, providing consistent, reliable results even in the most challenging conditions. Versatility: Compatible with various downhole tools and suitable for multiple applications, our LIBs are a versatile addition to any downhole toolset, making them ideal for a wide range of operations. Enhanced Safety: By providing accurate information about downhole conditions, our LIBs help minimize the risks associated with downhole operations, enhancing overall safety for personnel and equipment. Transform Your Downhole Operations with HOCA Oil Tools At HOCA Oil Tools, we're committed to innovation and excellence. Our Lead Impression Blocks are a testament to our dedication to providing the oil and gas industry with tools that not only meet but exceed expectations. By integrating our LIBs into your operations, you can expect enhanced diagnostic capabilities, improved operational efficiency, and reduced costs. Embrace the clarity and precision offered by HOCA's Lead Impression Blocks and experience a new level of downhole diagnostic prowess. Choose HOCA Oil Tools for all your downhole needs and unlock the full potential of your wellbore operations.

Buy

In Stock

Product & Service

New

API

Air Freight

![]() CWB National Leasing in Winnipeg

CWB National Leasing in Winnipeg

Expand Your Business Capabilities with Utility Trailer Leasing from CWB National Leasing Streamlining Operations with Flexible and Efficient Transportation Solutions For many businesses, utility trailers are an essential asset for transportation and logistics, providing the flexibility to move goods, equipment, and materials as needed. Leasing utility trailers through Canadian Western Bank (CWB) National Leasing offers a smart, financially viable option to enhance your operational capabilities. Here’s how leasing utility trailers can benefit your business: 1. Quick and Efficient Equipment Access CWB National Leasing values the pace of your business operations. They offer a rapid review and approval process for lease applications, typically providing a decision and notifying your equipment dealer about the payment within 48 hours. This prompt service ensures your utility trailers are delivered and ready for use quickly, aiding in keeping your business activities uninterrupted and efficient. 2. Improved Financial Flexibility Leasing utility trailers with CWB National Leasing boosts your buying power. It enables you to avoid large upfront purchases and instead opt for manageable periodic payments. This approach frees up capital for other critical business investments. Additionally, the flexibility to customize your trailers with additional features or accessories for a minimal increase in payments enhances their utility to suit specific business needs. 3. Optimal Cash Flow Management With smaller lease payments spread over the term, your utility trailers begin to contribute to your business’s revenue while still being paid off. This financial strategy is key in maintaining a favourable balance between expenses and income, which is essential for the growth and stability of your business. 4. Customizable Payment Plans Recognizing the diverse needs of businesses, CWB National Leasing offers various payment options, including seasonal, semi-annual, or annual plans, to align with your business’s revenue cycle. This flexibility is particularly beneficial for businesses with variable or seasonal income patterns, ensuring that payments are practical and aligned with your financial situation. 5. Potential Tax Benefits Leasing utility trailers can offer tax advantages, such as the ability to expense lease payments instead of capitalizing the cost of the equipment. It’s advisable to consult with a tax advisor to explore how leasing can positively impact your business’s tax position. Conclusion Opting to lease utility trailers through CWB National Leasing is a strategic decision that equips your business with vital transportation resources while maintaining financial agility. It ensures access to the necessary trailers for your logistics and delivery operations without the financial burden of a large upfront purchase, paving the way for enhanced operational efficiency, business expansion, and increased profitability.

Service

In Stock

Service

New

ISO

![]() Dunbridge Financial in Oakville

Dunbridge Financial in Oakville

Unlock Financial Freedom with Dunbridge Financial's Personal Services Are you seeking a financial service that puts your needs first and offers complete transparency, security, and convenience? Look no further than Dunbridge Financial's Personal Services. With a focus on empowering you to make the most of your money, we offer a range of features that are designed to simplify your financial life. Live Rates with No Hidden Fees At Dunbridge Financial, we believe in honesty and integrity. That's why we promise no hidden fees – what you see is what you get. Access our live exchange rates, ensuring you are always aware of the current rates and getting the best value for your money. With us, you can rest assured that there are no unpleasant surprises when it comes to your transactions. Security is Our Priority We understand that the security of your funds and data is of utmost importance. With Dunbridge Financial, you can trust that your assets are in safe hands. Our payment service partners are compliant with ISO27001, the internationally recognized standard for information security management systems. This means your client funds are managed with the highest level of safety and security, providing you with peace of mind throughout your financial journey. Easy to Use, Easy to Save Sending money to over 100 countries has never been easier. With Dunbridge Financial, you can quickly and effortlessly transfer funds to your desired destinations. Simply choose where and who you want to send money to, lock in your rate, and you're done – it's that simple! Our user-friendly platform ensures that managing your finances is a seamless experience, leaving you with more time to focus on what truly matters to you. Explore Our Foreign Investment Management Services At Dunbridge Financial, we go above and beyond to cater to your diverse financial needs. That's why we offer a comprehensive suite of Foreign Investment Management services. Whether you're managing investments in your home country while living abroad, exploring offshore investment opportunities, or paying your mortgage in a different country for that dream vacation villa or investment property – we have you covered. Additionally, our flexible currency options allow you to have your pay and expenses paid in your choice of currency, making it convenient and cost-effective for you to manage your finances internationally. Experience Financial Freedom Today With Dunbridge Financial's Personal Services, you can experience true financial freedom. Say goodbye to hidden fees and complicated processes – we keep things simple, secure, and transparent, so you can make the most out of your money without any worries. Join us today and discover a world of financial empowerment. Let us be your trusted partner on your financial journey, guiding you every step of the way towards a brighter and more prosperous future. Dunbridge Financial: Your Path to Financial Freedom Starts Here.

Service

Made to Order

Service

New

ISO

Air Freight

![]() Midastream Supply Company in Airdrie

Midastream Supply Company in Airdrie