Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

Also known as:

Service

In Stock

Service

New

API

Land Freight

Solutions

Comprehensive Pressure Management: Deploying advanced pressure control equipment for a wide range of well conditions.

Precision Perforating: Implementing precise perforating techniques for optimized reservoir connectivity and production.

Customized Equipment Manufacturing: Designing and manufacturing specialized tools for unique well service needs.

Environmental and Quality Compliance: Ensuring operations meet stringent environmental and quality standards.

Fishing and Retrieval: Providing expert fishing services for the retrieval of lost or stuck equipment.

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Revitalizing Wells with Precision: InWaTec Combined’s E-line Re-perforating Services In the lifecycle of an oil or gas well, the need to enhance production or manage reservoir depletion often leads to re-perforating—a strategic intervention aimed at revitalizing well performance. InWaTec Combined's E-line Re-perforating Services leverage the proven efficacy of wireline technology to refine and optimize this crucial process. Wireline, or electric line, has been the traditional mode for deploying perforating guns due to its substantial benefits. The real-time depth control ensures that each perforation is placed with surgical precision, while the selectivity afforded by wireline allows for targeted interventions, focusing on zones with the greatest potential for increased production. Moreover, the reduced logistics of wireline operations, as opposed to tubing deployment, offer a streamlined, cost-effective approach to well servicing. Historically, wireline perforating guns were differentiated based on their use—either as casing guns for pre-completion perforation or through-tubing guns for post-completion jobs. In today's industry, however, this distinction has been transcended. InWaTec Combined has embraced the versatility of wireline to deliver any engineered perforating system, regardless of the well's stage of life, alongside an extensive array of explosive devices. Our E-line Re-perforating Services are not merely about revisiting existing perforations. They represent a strategic re-evaluation and reconfiguration of the well's production strategy. Whether it's addressing areas of the reservoir that were initially bypassed, bypassing damaged perforations, or creating new pathways in depleted zones, our re-perforating services are tailored to meet the unique demands of each well. At InWaTec Combined, we understand that re-perforating is an opportunity to enhance well productivity significantly. Our expert teams, equipped with advanced diagnostic tools, evaluate the well's current status to identify the most promising zones for re-perforation. With this data, we employ the latest in shaped-charge technology and explosive devices, ensuring that new perforations deliver the maximum flow and recovery possible. Choosing InWaTec Combined's E-line Re-perforating Services means entrusting your well's performance to a company that values precision, efficiency, and innovation. Our commitment to excellence ensures that your re-perforating interventions are executed with the highest level of expertise, from planning to execution. Partner with us to revitalize your wells. With InWaTec Combined's E-line Re-perforating Services, you can expect to turn potential into production, optimizing your well's output and extending its productive life. Let us help you unlock the hidden value in your wells, one precise perforation at a time.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Enhancing Well Integrity in Hostile Environments: InWaTec Combined's Braided Line H2S Rated Wire and Tools Services In the challenging and often volatile conditions of oil and gas extraction, the durability and integrity of well intervention equipment are paramount. InWaTec Combined is at the forefront of providing robust solutions for environments where corrosive agents like CO2, H2S, and chlorides pose significant risks. Our Braided Line H2S Rated Wire and Tools Services are specifically engineered to withstand such harsh well conditions, ensuring safety, reliability, and performance. Our braided line services are not just a component of our offerings; they are a testament to our commitment to innovation and resilience. The braided wirelines we employ are fabricated with materials offering extraordinarily high stability against a spectrum of corrosive threats, including: Corrosion: Our lines are designed to resist the chemical attacks that are common in high CO2 environments, maintaining their integrity over time. Stress Corrosion: The high-stress conditions of downhole operations can lead to vulnerabilities in standard materials. Our H2S rated wires are built to endure these stresses without succumbing to corrosion. Intergranular Corrosion: This type of corrosion can compromise the grain boundaries of metals. Our wirelines are composed of alloys that maintain their structure even in the presence of corrosive elements. The presence of H2S, known for its corrosive nature and potential to create hazardous work conditions, demands a solution that not only withstands this environment but also ensures the safety of the operation. InWaTec Combined's H2S rated wires and tools are up to this task, providing a reliable means of well intervention and maintenance without the risk of degradation. Our services extend to a suite of tools compatible with these high-strength wirelines, ensuring that every aspect of the intervention process is optimized for H2S-rich environments. From logging to perforating, our tools are designed to perform flawlessly, providing accurate data and successful outcomes despite the presence of aggressive agents. Choosing InWaTec Combined's Braided Line H2S Rated Wire and Tools Services means opting for a partner with an uncompromising stance on safety and quality. We understand the challenges of operating in hostile well environments, and we are dedicated to providing solutions that meet these challenges head-on. With InWaTec Combined, operators can confidently address well intervention tasks in even the most demanding conditions, assured by our high-quality materials and cutting-edge technology. Our commitment to excellence is your pathway to maintaining well integrity and achieving uninterrupted production, even in the face of H2S and other corrosive agents. Trust InWaTec Combined to deliver resilience and reliability downhole, where it matters most.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Streamlining Wellbore Maintenance with Drive Down Bailer Services In the intricate world of well servicing, the importance of maintaining a clear and clean wellbore cannot be overstated. At InWaTec Combined, we understand the complexities of bailing operations, whether they are conducted on drilling rigs, during workover operations, or within production wells. That's why we are proud to offer our specialized Drive Down Bailer running services, providing a robust solution for the collection of solids and the overall cleansing of the wellbore environment, both onshore and offshore. Defining Bailing Operations with Excellence Bailing operations are essential for the upkeep of wellbore integrity, allowing for the efficient removal of debris that could potentially hinder well performance. InWaTec Combined's Drive Down Bailer services are meticulously designed to handle these operations with precision and reliability, ensuring that your wellbore remains free from obstructions that could impede operational success. Adaptable Services for Diverse Settings Our Drive Down Bailer services are versatile and adaptable, capable of being deployed in a variety of settings. Whether it’s the challenging offshore environment with its unique logistical demands or the accessibility of onshore operations, our services are tailored to meet the needs of the specific operation, ensuring the same high standards of quality and efficiency are maintained across all environments. Innovative Approach to Wellbore Cleaning InWaTec Combined utilizes the latest in bailing technology, equipping our Drive Down Bailers with the capacity to effectively collect and remove solids from the wellbore. Our approach to wellbore cleaning prioritizes not only the immediate removal of debris but also the long-term maintenance of the wellbore, ensuring continued productivity and reduced risk of downtime. Safety and Environmental Responsibility Recognizing the importance of safety and environmental stewardship, InWaTec Combined conducts all bailing operations with these as core priorities. Our Drive Down Bailer services are executed with the utmost attention to safety protocols, ensuring the well-being of all personnel involved, while also maintaining the integrity of the surrounding environment. InWaTec Combined: Your Trusted Partner in Well Servicing By choosing InWaTec Combined for your bailing needs, you are selecting a partner committed to delivering excellence. Our Drive Down Bailer running services are a reflection of our dedication to providing top-tier well servicing solutions that not only meet but exceed industry standards. We are dedicated to ensuring that your operations are carried out efficiently, safely, and with the highest degree of professionalism. Conclusion: Clearing the Path to Operational Excellence In conclusion, InWaTec Combined's Drive Down Bailer services offer a strategic advantage in well servicing operations. Our commitment to precision, adaptability, and safety ensures that we provide solutions that clear the path to operational excellence. Trust in the expertise and dedication of InWaTec Combined to keep your wellbore in optimal condition, ensuring the continued success and productivity of your well operations.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Streamlining Downhole Diagnostics: InWaTec Combined’s Integrated GR-CCL Services In the intricate world of well logging and evaluation, the ability to gather comprehensive data efficiently is a vital component of operational success. InWaTec Combined is proud to introduce our integrated Gamma Ray & Casing Collar Locator (GR-CCL) Services, a dual-function tool that synergizes gamma radiation measurement with precise casing collar detection. The GR-CCL is a testament to the power of combined diagnostics. It merges the functionality of a Gamma Ray tool, utilizing a Sodium Iodine Scintillation Detector, with the precision of a Casing Collar Locator. This powerful combination allows for the passive measurement of natural gamma radiation alongside the identification of changes in metal thickness, indicative of casing collars. Our GR-CCL Services empower operators with a two-fold diagnostic capability. The Gamma Ray aspect of the tool is essential for understanding the stratigraphy and identifying the presence of potentially productive zones. The Sodium Iodine Scintillation Detector is meticulously calibrated to capture the nuances of gamma radiation within the geological formations, providing a reliable indicator of downhole lithology. Simultaneously, the CCL component of the GR-CCL tool pinpoints the precise location of casing collars. This feature is crucial for depth correlation and ensuring that interventions such as perforating or sidetracking are executed at the correct depths. The ability to detect changes in metal thickness with high accuracy ensures that operators have a clear understanding of the casing's structural transitions. By integrating these two critical measurements, InWaTec Combined’s GR-CCL Services eliminate the need for multiple runs, saving time and reducing operational costs. The efficiency of this dual-action tool translates into faster decision-making and enhanced well intervention planning. InWaTec Combined’s commitment to innovation is embodied in our GR-CCL Services, where we provide more than just data—we offer a comprehensive solution that enhances the accuracy and efficiency of well logging operations. By deploying our GR-CCL tool, clients benefit from a streamlined approach to well diagnostics, bolstering their ability to make informed decisions with confidence. Choose InWaTec Combined’s GR-CCL Services for your well logging needs and embrace the clarity and precision that come with cutting-edge downhole diagnostic technology. Let our integrated solutions illuminate the path to optimized well performance and operational excellence.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Precision Perfected with Our Broaching Tool Running Services In the complex tapestry of well service operations, precision is not just a goal—it's a necessity. At InWaTec Combined, we infuse this precision into every aspect of our work, especially when it comes to preparing wellbore tubing for subsequent interventions. Our Broaching Tool Running services epitomize this commitment, ensuring that wellbore tubings are in optimal condition for running or pulling service tools. The Critical Role of Broaching The wellbore is the heart of any drilling operation, and like any heart, it must be free from obstructions to function correctly. Enter the broach—InWaTec Combined’s answer to the industry's need for flawless tubing surfaces. Our broaching tools are engineered to meticulously remove metal burrs and imperfections that could jeopardize the integrity of service operations. By ensuring a clean and smooth tubing wall, we set the stage for efficient and trouble-free servicing. Advanced Broaching Technology Our broaching tools are not just tools; they are precision instruments. Equipped with graduated rings, diamonds, or segments, our broaches are case-hardened to withstand the rigors of the well environment. Their highly sharpened edges are designed to cut through imperfections with surgical precision, leaving behind a surface that meets the industry's highest standards. The InWaTec Combined Edge When you choose InWaTec Combined for broaching tool running services, you're not just getting a service; you're acquiring a partnership that values excellence. We understand that the quality of broaching directly impacts the success of your subsequent operations. That's why we've invested in developing a team of experts and a fleet of tools that stand unrivaled in quality and performance. Ensuring Success Down the Line Our broaching service is a critical precursor to a variety of downhole operations. By preparing your tubing with our broaching tools, you are ensuring that subsequent tools can be run or pulled with minimal risk of snagging or damage, thus preserving the integrity of your operations. This not only saves time but also reduces the likelihood of costly interruptions. Your Assurance of Quality At InWaTec Combined, our reputation is built on the back of our commitment to quality and precision. Our broaching tool running services are a testament to this promise. We don’t just deliver a service—we ensure that your wellbore is in the best possible condition for whatever comes next. In conclusion, with InWaTec Combined's Broaching Tool Running services, you can rest assured that the critical first step in your well servicing operations is in the most capable hands. Our precision tools and expert operators stand ready to deliver a seamless service experience that sets a solid foundation for your well's longevity and productivity.

Service

In Stock

Service

New

API

Land Freight

General Mechanical Slickline Service

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Precision at Depth with General Mechanical Slickline Services In the demanding arena of oil and gas well maintenance, precision is not just a virtue—it's a necessity. At InWaTec Combined, we provide General Mechanical Slickline services that bring precision to the heart of your well operations. Our slickline services deliver targeted maintenance solutions, assuring that performance, integrity, and productivity remain at the forefront of your downhole activities. The Role of Slickline in Downhole Maintenance Slickline is the unsung hero of well servicing, a slender thread of robustness, lowering essential tools into the depths of oil and gas wells to execute critical maintenance tasks. It is the conduit for precision, the means by which tools are delivered to the precise downhole location where they are needed. Why Choose InWaTec Combined's Slickline Services? Expertise at Every Turn: Our slickline operators are seasoned experts, with the skill to navigate complex downhole environments, ensuring that every tool is deployed with accuracy. Versatile Tool Deployment: From routine maintenance to emergency interventions, our slickline services cater to a diverse range of downhole needs, delivering the right tool to the right place at the right time. Streamlined Operations: Efficiency is key in downhole operations, and our slickline services are designed to minimize downtime, streamline processes, and maintain the peak performance of your wells. Safety and Precision Combined: At InWaTec Combined, we balance the need for operational precision with an uncompromising commitment to safety, ensuring that every slickline operation upholds the highest standards. Tailored Solutions for Downhole Challenges Every well presents its own set of challenges, and InWaTec Combined's General Mechanical Slickline services are crafted to meet them head-on. We provide tailored solutions, customizing our approach to fit the unique needs of your well, ensuring that maintenance tasks are carried out with precision and care. Advanced Technology for Optimal Results We leverage the latest in slickline technology, utilizing advanced materials and innovative techniques to enhance the reliability and effectiveness of our services. Our commitment to technological advancement means that we're always at the cutting edge, providing services that are not just current but future-ready. Your Partner in Well Maintenance Choosing InWaTec Combined for your slickline needs means selecting a partner dedicated to the success of your well operations. Our General Mechanical Slickline services are a reflection of our promise to deliver excellence in every aspect of our work, from the initial deployment of tools to the completion of maintenance tasks. Conclusion: Your Well's Performance, Our Commitment In conclusion, InWaTec Combined's General Mechanical Slickline services are essential for maintaining the high performance and integrity of your oil and gas wells. With our focus on precision, efficiency, and safety, we ensure that your maintenance operations are performed to the highest standards. Trust in the expertise and dedication of InWaTec Combined to keep your wells operating smoothly, safely, and efficiently.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Enhancing Well Intervention with Precision Dump Bailer Services In the world of well intervention, precision and reliability are paramount. InWaTec Combined is proud to introduce our Dump Bailer services—a cost-effective and efficient solution for transporting fluids to precise points within the wellbore. These services are essential for various applications, ensuring that operations are not only successful but also streamlined for maximum efficiency. Strategic Applications for Optimal Results Our Dump Bailer services are versatile, serving a range of critical applications: Cementing Operations: Deploying cement onto permanent plugs to secure well integrity is executed with precision, ensuring that the cement is placed exactly where it is needed. Acidizing: We specialize in depositing acid precisely at scale restrictions or on flow control items, which may be scaled up to restore functionality and enhance flow. These strategic applications are vital in extending the life of wells and restoring their optimal functionality. Features & Benefits: A Blend of Simplicity and Efficiency InWaTec Combined’s Dump Bailers are designed with the industry's needs in mind, and they come with a host of features and benefits: Standard Slickline Connections: Our dump bailers are equipped with industry-standard connections, ensuring compatibility with a wide range of toolstrings and ease of integration. Simple, Robust Design: Durability and ease of use are at the heart of our design philosophy, providing a tool that withstands the rigors of well operations while being user-friendly. Quick and Easy Field Redress: Time is of the essence in well operations, and our dump bailers are designed for rapid redress in the field, minimizing downtime. Modular Design Flexibility: We understand that well conditions vary, which is why we offer modular designs that allow for field changeable variations in length to suit any well's requirements. Customizable Burst Discs: With the ability to supply various burst discs, we tailor our tools to suit every unique application, ensuring that the operation is conducted with the right specifications for optimal results. Cost-Effectiveness: Our Dump Bailer services provide a cost-effective method for fluid transport within the wellbore, ensuring that budgetary constraints do not compromise well servicing operations. A Partner in Well Intervention At InWaTec Combined, we stand as your partner in well intervention. Our Dump Bailer running services are a testament to our commitment to providing solutions that are not just effective but also enhance the safety and efficacy of your well operations. Conclusion: Precision Fluid Deployment with InWaTec Combined In summary, InWaTec Combined's Dump Bailer services represent an essential component in the well servicing toolkit. With our focus on precision, ease of use, and cost-effectiveness, we ensure that your well intervention operations are performed with the highest standards of accuracy and efficiency. Choose InWaTec Combined for services that deliver where it counts—down the wellbore.

Service

In Stock

Service

New

API

Land Freight

Ultra-Sonic Inspection Tool (USIT) runs

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Advancing Well Integrity with InWaTec Combined’s Ultra-Sonic Inspection Tool Services In the pursuit of operational excellence within the oil and gas industry, maintaining the integrity of well infrastructure is paramount. InWaTec Combined is proud to present our Ultra-Sonic Inspection Tool (USIT) Services, a cutting-edge solution for comprehensive cement evaluation, casing inspection, and integrity assessment. The USIT is a marvel of diagnostic precision, utilizing a single transducer mounted on an Ultrasonic Rotating Sub (USRS) at the tool's base. This sophisticated apparatus emits ultrasonic pulses ranging from 200 to 700 kHz, meticulously recording the waveforms reflected from both internal and external casing interfaces. The decay rate of these waveforms is a direct indicator of the cement bond's quality, while the resonant frequency readings of the casing yield accurate wall thickness measurements—critical data for assessing pipe integrity. Thanks to the transducer's placement on the rotating sub, our USIT Services ensure a full 360° scan of the casing circumference, leaving no aspect of the wellbore unexamined. This comprehensive coverage is pivotal for evaluating cement bond quality and determining the condition of the casing with unmatched precision. Our tool’s high angular and vertical resolutions can detect even the narrowest channels, down to 1.2 inches in width, providing a detailed assessment of well integrity. Our real-time data acquisition and analysis at the wellsite generate self-explanatory maps and valuable metrics, including cement bond logs, casing thickness, internal and external radii. These insights are indispensable for: Cement evaluation to ensure zonal isolation and well integrity. Casing inspection to ascertain ongoing wellbore stability. Corrosion detection and monitoring to prevent potential well failures. Identification of internal and external damage or deformation, safeguarding against unexpected operational hazards. Casing thickness analysis, crucial for calculating collapse and burst pressure parameters and prolonging the life of the well. InWaTec Combined's USIT Services are not just diagnostic tools—they are a testament to our commitment to safeguarding our clients' assets and optimizing well performance. By embracing our Ultra-Sonic Inspection Tool Services, operators gain the assurance that their wells remain robust, compliant, and productive throughout their lifecycle. In an industry where well integrity is synonymous with operational success, InWaTec Combined stands as your sentinel of safety and efficiency. Deploy our USIT Services, and harness the power of precision ultrasonic technology to illuminate the unseen, ensuring your operations are secure from the inside out.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Streamlining Well Integrity with Expert Mechanical Plug Operations In the intricate sphere of well servicing, the ability to effectively isolate sections of the wellbore is crucial. At InWaTec Combined, we specialize in providing top-tier Pulling and Setting Mechanical Plug services that ensure well integrity through precision and reliability, all achieved via mechanical wireline manipulation. Sophisticated Simplicity in Well Isolation Our mechanical plug services are designed to provide a seamless solution for wellbore isolation. The mechanical plugs can be set using the finesse of wireline operations alone, without the need for complex hydraulic systems. This method exemplifies our commitment to sophisticated yet simple solutions, providing our clients with a straightforward and efficient means to secure their wells. Tailored Tools for Diverse Requirements Recognizing that wells come in various sizes and specifications, InWaTec Combined has developed a selection of running tools to match. Depending on the size of the mechanical plug, we employ one of two specialized running tools. Each tool is designed to engage with the plug precisely, ensuring a secure and accurate setting every time. Versatility Across Operations Whether it’s a routine intervention or an emergency response, our Pulling and Setting Mechanical Plug services are versatile enough to adapt to the specific needs of the operation. This versatility is a testament to the depth of our expertise and the breadth of our technological capabilities. Efficiency in Execution The use of mechanical wireline manipulation for setting and pulling plugs not only provides precision but also enhances operational efficiency. By eliminating the need for additional hydraulic equipment, we can execute operations more quickly, reducing downtime and optimizing well productivity. A Commitment to Operational Excellence At InWaTec Combined, our services are underpinned by a steadfast commitment to operational excellence. We don’t just deliver tools and technologies; we provide a partnership that prioritizes the integrity and productivity of your well operations. Our experienced technicians and state-of-the-art equipment stand ready to deliver results that exceed expectations. Conclusion: Ensuring Well Integrity with Precision In conclusion, InWaTec Combined's Pulling and Setting Mechanical Plug services represent the pinnacle of well intervention solutions. Our precision-engineered tools and expert wireline manipulation techniques ensure that well integrity is maintained with the utmost efficiency and reliability. Trust InWaTec Combined to be your partner in well servicing operations, where every plug set is a step towards ensuring the ongoing success and safety of your well activities.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Enhancing Snubbing Operations: InWaTec Combined’s High-Pressure Mini-Coil Services At InWaTec Combined, we understand the critical nature of snubbing operations in well intervention and maintenance. Our Mini-Coil Tubing services are specifically designed to enhance these operations, providing a solution that balances the delicate requirements of fluid placement and well lifting with the necessity for high-pressure performance. Optimal Fluid Placement: The Mini-Coil Tubing is adept at delivering small quantities of fluids precisely where they are needed. This precise placement is particularly beneficial during snubbing operations, where control and accuracy are paramount to successful well control and intervention. Efficient Well Lifting: When it comes to lifting wells into production, especially during snubbing operations, our Mini-Coil Tubing shines with its ability to handle high pumping pressures. This capability ensures that wells are brought into production efficiently and reliably. High-Pressure Operations: While Mini-Coil Tubing may face limitations in flow rate and mechanical snubbing force due to its smaller size, it compensates with an exceptional capacity for withstanding higher pumping pressures. This makes it particularly useful in situations where pressure integrity is crucial. The nature of snubbing operations often involves dealing with wells under pressure. The high-pressure resistance of our Mini-Coil Tubing means it can be deployed in environments that are too challenging for larger, conventional coiled tubing. This feature opens up new possibilities for conducting critical well interventions safely and effectively. InWaTec Combined's Mini-Coil Services are not just about providing equipment; they're about delivering a comprehensive solution. We understand that each well and operation has its unique set of challenges. Our Mini-Coil Tubing services are complemented by a team of experienced professionals who ensure that every operation is executed with precision, efficiency, and adherence to the highest safety standards. Customized Solutions: Recognizing the unique demands of each operation, InWaTec Combined offers customized Mini-Coil solutions. We work closely with clients to understand their specific needs and challenges, ensuring our Mini-Coil Tubing services are tailored to meet the particular requirements of their snubbing operations. Choose InWaTec Combined for your snubbing operation needs, and benefit from the advanced performance of our Mini-Coil Tubing services. Our commitment to innovation, safety, and operational excellence ensures your operations are not just maintained but enhanced. Let us help you achieve your well intervention goals with our high-pressure, precision-driven Mini-Coil services.

Service

In Stock

Service

New

API

Land Freight

General Mechanical Slickline Service

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Precision at Depth with General Mechanical Slickline Services In the demanding arena of oil and gas well maintenance, precision is not just a virtue—it's a necessity. At InWaTec Combined, we provide General Mechanical Slickline services that bring precision to the heart of your well operations. Our slickline services deliver targeted maintenance solutions, assuring that performance, integrity, and productivity remain at the forefront of your downhole activities. The Role of Slickline in Downhole Maintenance Slickline is the unsung hero of well servicing, a slender thread of robustness, lowering essential tools into the depths of oil and gas wells to execute critical maintenance tasks. It is the conduit for precision, the means by which tools are delivered to the precise downhole location where they are needed. Why Choose InWaTec Combined's Slickline Services? Expertise at Every Turn: Our slickline operators are seasoned experts, with the skill to navigate complex downhole environments, ensuring that every tool is deployed with accuracy. Versatile Tool Deployment: From routine maintenance to emergency interventions, our slickline services cater to a diverse range of downhole needs, delivering the right tool to the right place at the right time. Streamlined Operations: Efficiency is key in downhole operations, and our slickline services are designed to minimize downtime, streamline processes, and maintain the peak performance of your wells. Safety and Precision Combined: At InWaTec Combined, we balance the need for operational precision with an uncompromising commitment to safety, ensuring that every slickline operation upholds the highest standards. Tailored Solutions for Downhole Challenges Every well presents its own set of challenges, and InWaTec Combined's General Mechanical Slickline services are crafted to meet them head-on. We provide tailored solutions, customizing our approach to fit the unique needs of your well, ensuring that maintenance tasks are carried out with precision and care. Advanced Technology for Optimal Results We leverage the latest in slickline technology, utilizing advanced materials and innovative techniques to enhance the reliability and effectiveness of our services. Our commitment to technological advancement means that we're always at the cutting edge, providing services that are not just current but future-ready. Your Partner in Well Maintenance Choosing InWaTec Combined for your slickline needs means selecting a partner dedicated to the success of your well operations. Our General Mechanical Slickline services are a reflection of our promise to deliver excellence in every aspect of our work, from the initial deployment of tools to the completion of maintenance tasks. Conclusion: Your Well's Performance, Our Commitment In conclusion, InWaTec Combined's General Mechanical Slickline services are essential for maintaining the high performance and integrity of your oil and gas wells. With our focus on precision, efficiency, and safety, we ensure that your maintenance operations are performed to the highest standards. Trust in the expertise and dedication of InWaTec Combined to keep your wells operating smoothly, safely, and efficiently.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Ensuring Continuity with InWaTec Combined’s Electric Line Pipe Recovery Services In the dynamic arena of oil and gas extraction, the unexpected is the only constant. One of the most formidable challenges that can grind operations to a halt is the dreaded scenario of a stuck drill string. Recognizing the critical need for swift and effective resolution, InWaTec Combined offers specialized Electric Line Pipe Recovery Services, designed to address and rectify such downhole dilemmas. When a drill string becomes lodged downhole, it is not just an obstacle; it represents a halt in production, potential damage to resources, and a significant operational cost. InWaTec Combined's Electric Line Pipe Recovery Services are the answer to this industry-wide challenge. Our services employ advanced wireline technology, leveraging the power of electric lines to deliver targeted interventions that free the stuck pipe. Our approach to pipe recovery combines precision-engineered tools with real-time data transmission capabilities. This dual advantage enables our skilled operators to assess the situation accurately and execute recovery procedures with minimal risk to the wellbore or the environment. By integrating our electric line expertise with our pipe recovery operations, we ensure that your drill rig can return to its primary function with minimal downtime. The electric lines play a crucial role; they not only serve as a conduit for the necessary tools to navigate the wellbore but also provide a continuous stream of data back to the surface. This data is critical for making informed decisions during the recovery process, allowing for adjustments and interventions that are precise and situation-specific. At InWaTec Combined, we understand that time is of the essence in such operations. Our Electric Line Pipe Recovery Services are designed for rapid deployment and execution, ensuring that your operations can swiftly transition from a state of suspension to full productivity. Our commitment to innovation, safety, and efficiency is unwavering, as we strive to provide solutions that minimize operational disruptions and maintain the integrity of your wellbore. In the face of stuck pipe challenges, you can count on InWaTec Combined to deliver not just services, but solutions that propel your operations forward. Trust in our expertise to navigate the complexities of downhole recovery, ensuring that your operations remain resilient and robust, no matter what obstacles lie beneath.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

InWaTec Combined: Enhancing Wellbore Clarity with Advanced Hydrostatic Bailer Services In the diverse and demanding world of well servicing, maintaining a clear and functional wellbore is essential for the efficient operation of drilling rigs, workover operations, and production wells. InWaTec Combined stands at the forefront of this vital service with our Hydrostatic Bailer running services, offering a sophisticated solution to the age-old challenge of collecting solids and cleaning the wellbore. The Necessity of Hydrostatic Bailer Operations Hydrostatic Bailers are an integral component in the suite of tools required for effective well maintenance. The principle behind these tools is simple yet ingenious—they utilize the pressure differential created by the well fluid to draw debris into the bailer, effectively removing it from the wellbore. This operation is crucial, as it ensures that the wellbore is free from obstructions that could hinder subsequent interventions or impede production. Versatile Solutions for Onshore and Offshore Operations Whether dealing with onshore wells nestled in the heart of a bustling oil field or offshore platforms braving the open seas, InWaTec Combined’s Hydrostatic Bailer services are designed to adapt to any environment. Our tools and techniques are as versatile as they are effective, ensuring that no matter the location, the cleanliness and functionality of the wellbore can be maintained to the highest standards. Technology-Driven Efficiency InWaTec Combined’s commitment to technological innovation is embodied in our Hydrostatic Bailer services. By employing the latest advancements in well servicing technology, we provide a more efficient and reliable means of wellbore cleaning. This not only optimizes the bailing process but also translates into significant time and cost savings for our clients. Prioritizing Safety and Environmental Stewardship Safety and environmental protection are paramount in all of InWaTec Combined’s operations. Our Hydrostatic Bailer services are conducted with strict adherence to safety protocols, ensuring the well-being of personnel and the preservation of the environment. We understand the importance of responsible operations, especially in sensitive onshore and offshore locations. Your Partner in Operational Excellence Choosing InWaTec Combined for your Hydrostatic Bailer needs means partnering with a company that is dedicated to excellence. Our Hydrostatic Bailer running services are a testament to our commitment to providing solutions that are not just effective but also enhance the safety and efficacy of your well operations. Conclusion: Clarity in Every Operation In conclusion, InWaTec Combined’s Hydrostatic Bailer services represent an essential component in the well servicing toolkit. With our focus on precision, efficiency, safety, and environmental responsibility, we ensure that your wellbore cleaning operations are performed to the highest standards. Trust InWaTec Combined to deliver clear solutions for your wellbore challenges, ensuring the uninterrupted success and productivity of your operations.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Elevating Well Integrity Analysis with InWaTec Combined's CBL-VDL Services Ensuring a solid cement bond between casing and the wellbore is not just a procedural step; it's a critical factor in well integrity that demands the most meticulous evaluation techniques. InWaTec Combined’s Cement Bond Logging (CBL) and Variable Density Logging (VDL) Services offer a refined approach to acoustic well logging, a method that has been a research focal point due to its importance in ascertaining well safety and functionality. Cement bonding evaluation can be segmented into two categories based on tool source frequency: the sonic method (around 20 kHz) and the ultrasonic method (several hundred thousand Hz). The sonic method, a technique that has stood the test of time since its introduction in 1963, provides a qualitative or semi-quantitative analysis of the cement bond. It involves the excitation of a sonic wave and measurement of its attenuation along the borehole axis, with the degree of attenuation reflecting the quality of shear coupling behind the casing. Simply put, the greater the attenuation, the better the bond. CBL specifically focuses on the attenuation factor derived from the first arrival amplitude, offering a snapshot of the bond's integrity. In contrast, VDL takes into account the full waveform amplitude, providing a more detailed and denser representation of the bond quality. These dual measurements, with industry-standard receiver spacings of 3-ft for the casing wave and 5-ft for the full wave, allow for a comprehensive analysis of the cement bond. InWaTec Combined's CBL-VDL Services employ these methodologies with precision-engineered tools that capture high-resolution data, enabling our experts to discern even subtle variations in bonding conditions. This data is not merely numbers on a log; it's a story of the well's integrity, revealing areas of potential concern that can be proactively addressed to prevent non-productive time and ensure operational safety. By leveraging the combined strengths of CBL and VDL, InWaTec Combined provides clients with a robust assessment of their cementation quality. The detailed logs produced not only satisfy regulatory requirements but empower operators with actionable insights to optimize their well construction and maintenance strategies. Choose InWaTec Combined's CBL-VDL Services for your cement bond evaluation needs and gain peace of mind with our thorough, reliable, and cutting-edge acoustic logging solutions. Our commitment to excellence in well logging means that when it comes to well integrity, you're not just meeting industry standards—you're setting them.

Service

In Stock

Service

New

API

Land Freight

![]() InWaTec Combined in Vechta

InWaTec Combined in Vechta

Revolutionizing Geothermal Well Interventions: InWaTec Combined's Mini-Coil Services In the dynamic world of geothermal energy production, where the efficient management of well interventions is paramount, InWaTec Combined is pioneering with our Mini-Coil Services. Designed to navigate the unique challenges of geothermal wells, our Mini-Coil Tubing offers a versatile and high-pressure tolerant solution for fluid placements and well stimulation. Geothermal wells demand a delicate balance between precision and strength. Our Mini-Coiled Tubing services are tailored to meet these needs, providing an ideal solution for the small quantity placements of fluids that are often required in geothermal operations. Whether it's for precision acidizing, scale removal, or other chemical treatments, the Mini-Coil is an invaluable tool. Compact Power: Our Mini-Coiled Tubing is compact yet robust, designed to handle the high pumping pressures needed for effective interventions in geothermal wells. Its smaller diameter does not compromise its ability to withstand intense conditions underground. Efficiency in Production: Lifting wells into production efficiently is crucial for maintaining the economic viability of geothermal operations. The Mini-Coil facilitates this by enabling operators to deliver targeted treatments and interventions that can revitalize well performance. Tailored to Geothermal Needs: While traditional coiled tubing operations may be limited by flow and snubbing capabilities, our Mini-Coil Tubing is engineered to overcome these constraints, providing enhanced pressure handling that is especially beneficial in the high-temperature, high-pressure environments characteristic of geothermal wells. It's true that Mini-Coil Tubing has its limitations regarding flow and snub, but what it offers in return is the capacity to handle significantly higher pumping pressures. This attribute is particularly advantageous in geothermal applications where the subsurface conditions can be extreme. InWaTec Combined's commitment to innovation is further demonstrated by the integration of advanced monitoring technologies that accompany our Mini-Coil Services. Real-time data acquisition allows for precise control and assessment of the intervention process, ensuring that operations are not only successful but also conducted with an emphasis on safety and sustainability. In the realm of geothermal energy, where the right interventions can drastically enhance the output and longevity of wells, InWaTec Combined's Mini-Coil Services emerge as a clear choice for operators seeking to optimize their wells. Our services are a testament to our dedication to providing solutions that are both efficient and effective, reducing downtime and maximizing production. Partner with InWaTec Combined for your geothermal well needs and experience the next level of well intervention services. Let our Mini-Coil Tubing unlock the full potential of your geothermal operations, where precision meets power, and innovation drives production.

Service

In Stock

Service

New

API

Land Freight

InWaTec Combined: Ensuring Well Integrity with Advanced Pulling and Setting SCSSV Services The oil and gas industry faces the critical challenge of maintaining well integrity for uninterrupted production. At InWaTec Combined, we understand the importance of robust well operations, and our Pulling and Setting Surface Controlled Subsurface Safety Valve (SCSSV) services are at the forefront of addressing this challenge. Revolutionizing DHSV Repair A malfunctioning Downhole Safety Valve (DHSV) can halt production and compromise well integrity, making timely and efficient repairs crucial. Our services are meticulously designed to repair Tubing Retrievable Subsurface Safety Valves (TRSSSV), a process that not only restores well integrity but also resumes production swiftly. By repairing TRSSSVs, we circumvent the need for lock open operations, avoiding the necessity of installing a Wireline Retrievable Subsurface Safety Valve (WRSSSV) which could potentially restrict production flow. Optimized Repair Techniques Conventional repair methods are often time-consuming and costly, requiring extensive workover operations. InWaTec Combined’s approach replaces these outdated methods with cutting-edge techniques that save time and reduce costs. Our expertise in pulling and setting SCSSVs ensures that if a TRSSSV's functionality and integrity cannot be restored, it can be locked open efficiently. We then install a WRSSSV, which is a strategic move that prevents the need for a complex workover, thereby optimizing the repair process. Maintaining Peak Performance The ability to swiftly switch from a TRSSSV to a WRSSSV without a full workover is a game-changer in well service operations. It minimizes downtime and ensures that wells can continue to operate at peak performance levels. Our dedicated teams are equipped with the latest technology and have the expertise to execute these operations seamlessly, ensuring minimal disruption to your production schedules. A Partner in Well Integrity At InWaTec Combined, we pride ourselves on being your trusted partner in maintaining well integrity. Our Pulling and Setting SCSSV services are not just about repairs; they are about providing a comprehensive solution that safeguards your operations against future integrity issues. With our advanced techniques and committed service, we guarantee that your wells remain productive, secure, and profitable. In conclusion, InWaTec Combined is dedicated to providing superior service in the repair and maintenance of SCSSVs. Our innovative approach is designed to keep your wells functioning smoothly, ensuring that well integrity is not just restored but fortified. Trust us to be the guardians of your well's safety and productivity.

Flow Release Overshot for Coiled Tubing

FRO Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the FRO (Flow Release Overshot) from Marlin Oil Tools: Your Ultimate Solution for Efficient Fishing Operations in Oil and Gas Well Interventions Marlin Oil Tools is proud to present the FRO (Flow Release Overshot), a sophisticated downhole tool specifically designed to revolutionize fishing operations during well intervention. The FRO is engineered to offer unparalleled efficiency and reliability in capturing and retrieving objects ("fish") from the wellbore, ensuring smooth and successful operations. With its replaceable collet and adaptable design, the FRO is a must-have tool for any well intervention toolkit. Key Features of the FRO (Flow Release Overshot): Versatile Collet Design: The FRO features a replaceable collet system designed to catch and secure a smooth surface of fish, accommodating a wide range of outer diameters from 1.0” to 2-1/8”. Customizable Bottom Guide: Upon client request, the bottom of the overshot can be equipped with a guide leap, enhancing its ability to guide and catch fish with precision. Secure Fish Retrieval: The collet of the FRO overshot securely grips the fish, holding it firmly during the lifting process out of the well, ensuring safe and efficient retrieval. Pressure-Release Mechanism: In situations where the captured object cannot be released from the well, the FRO allows for an easy disengagement by applying pressure through the coil tubing, offering an additional layer of operational safety. SEO Optimized Description for Marlin Oil Tools’ FRO: Elevate your well intervention and fishing operations with the FRO (Flow Release Overshot) from Marlin Oil Tools, a leading downhole tool engineered for maximum retrieval efficiency in the oil and gas industry. Featuring a replaceable collet for capturing a range of fish sizes and an optional guide leap for enhanced precision, the FRO ensures secure and successful fish recovery. With its unique pressure-release mechanism, the FRO offers an innovative solution for challenging fishing scenarios, making it an essential component of your well intervention arsenal. Choose the FRO for reliable, efficient, and safe fishing operations. Why Choose the FRO from Marlin Oil Tools? Adaptable to Various Fish Sizes: Designed to accommodate a broad range of fish diameters, ensuring versatility across operations. Enhanced Precision and Safety: Optional guide leap improves catch accuracy, while the secure grip minimizes risks during retrieval. Innovative Release Mechanism: Provides a reliable method for disengaging from stubborn fish, enhancing operational flexibility. Durability and Reliability: Constructed to withstand the harsh conditions of downhole environments, ensuring consistent performance. The FRO (Flow Release Overshot) by Marlin Oil Tools represents the forefront of innovation in well intervention fishing operations. Incorporate the FRO into your operations to achieve optimal outcomes in fish retrieval, backed by the reliability and efficiency Marlin Oil Tools is known for.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the KNJ Knuckle Joint from Marlin Oil Tools: The Essential Downhole Tool for Enhanced Flexibility in Well Intervention Operations Marlin Oil Tools proudly presents the KNJ Knuckle Joint, a state-of-the-art downhole tool engineered to provide unparalleled flexibility to the Bottom Hole Assembly (BHA) during well intervention tasks. Designed to navigate through the most challenging sections of the well, including sharp narrows, thresholds, and various obstacles, the KNJ Knuckle Joint is an indispensable tool for ensuring the success and efficiency of well interventions. Key Features of the KNJ Knuckle Joint: Superior BHA Flexibility: The KNJ Knuckle Joint significantly enhances the flexibility of the BHA, enabling it to easily navigate through complex wellbore geometries. Overcomes Downhole Obstacles: Specifically designed to aid in overcoming difficult wellbore obstacles, the KNJ ensures smooth passage in areas that would otherwise pose significant challenges. Seamless Integration: The KNJ Knuckle Joint integrates seamlessly with other downhole tools within the BHA, providing a cohesive solution for well intervention operations. Optimized Well Intervention: By allowing for enhanced maneuverability and flexibility, the KNJ Knuckle Joint optimizes well intervention procedures, reducing the risk of tool sticking and minimizing the need for additional runs. SEO Optimized Description for Marlin Oil Tools’ KNJ Knuckle Joint: Elevate your well intervention capabilities with the KNJ Knuckle Joint from Marlin Oil Tools, a leading-edge solution designed to enhance the flexibility and maneuverability of the BHA in challenging wellbore environments. Tailored for navigating sharp narrows, thresholds, and other downhole obstacles, the KNJ Knuckle Joint is essential for any operation requiring advanced BHA adaptability. Its seamless integration with other downhole tools ensures a comprehensive approach to well intervention, making the KNJ Knuckle Joint a must-have for overcoming complex well geometries and optimizing intervention success. Why Choose the KNJ Knuckle Joint from Marlin Oil Tools? Enhanced Operational Flexibility: Maximizes BHA adaptability to navigate complex wellbore paths efficiently. Critical for Challenging Wellbores: Designed to tackle the most difficult downhole conditions, ensuring smooth operation. Increases Intervention Success: Reduces the likelihood of tool sticking and operational delays, enhancing overall success rates. Versatile and Reliable: A versatile tool that offers reliability and performance, crucial for a wide range of well intervention scenarios. The KNJ Knuckle Joint by Marlin Oil Tools represents the pinnacle of downhole tool innovation, offering operators the flexibility and reliability needed to tackle the most challenging well intervention tasks. Incorporate the KNJ Knuckle Joint into your well intervention toolkit to achieve superior performance and operational efficiency.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Poseidon Robotics in Chandler

Poseidon Robotics in Chandler

Empowering Your ROV: Introducing Poseidon Robotics' Mini-HPU (Hydraulic Power Unit) At Poseidon Robotics, we are committed to pushing the boundaries of subsea exploration and ensuring that your ROV missions are equipped with cutting-edge technology. Our latest innovation, the Mini-HPU (Hydraulic Power Unit), is designed to deliver unmatched power and reliability, elevating the capabilities of your hydraulic manipulators and tools on larger ROVs. Compact Powerhouse Don't let the size fool you! The Mini-HPU may be compact, but it packs a powerful punch. With a robust 3 horsepower output, this little dynamo is built to handle the most demanding subsea tasks with ease. The Mini-HPU provides the muscle you need to operate hydraulic manipulators and tools on larger ROVs effectively. Integrated Efficiency Efficiency is the name of the game, and the Mini-HPU excels in this aspect. Integrated within its sleek design is a convenient 1-gallon reservoir, ensuring an uninterrupted flow of hydraulic fluid to keep your operations running smoothly. No need to worry about external reservoirs, as everything you need is perfectly contained within this powerful unit. Adjustable Pressure Relief and Replaceable Filters We understand the importance of adaptability in your subsea operations. The Mini-HPU features an adjustable pressure relief valve, allowing you to fine-tune the pressure to suit your specific needs. Additionally, we've equipped this hydraulic power unit with easily replaceable filters, ensuring that your system stays clean and optimized for peak performance. Reliability at Its Core At Poseidon Robotics, we believe in building products that stand the test of time. The Mini-HPU is no exception. Its high reliability fixed displacement pump ensures consistent and dependable performance, allowing you to focus on your mission without worrying about equipment failures. Unleash Your ROV's Potential With a maximum pressure of 2,500 PSI and a maximum flow of 1.6 gallons per minute (standard pump), the Mini-HPU is a formidable force in the subsea realm. It's designed to tackle a wide range of applications, from deep-sea exploration to intricate industrial tasks. Corrosion-Resistant Design The subsea environment can be harsh and unforgiving, but the Mini-HPU is ready for the challenge. Our engineers have crafted the unit with anodized aluminum, providing exceptional corrosion resistance and eliminating the need for additional paint coatings. Your Trusted Subsea Partner Poseidon Robotics takes immense pride in being a trusted partner for subsea robotics and ROV companies worldwide. The Mini-HPU is a testament to our commitment to delivering advanced solutions that elevate your capabilities and redefine what's possible in the underwater world. Experience the Mini-HPU Difference Ready to take your ROV missions to new depths? Explore the power and versatility of Poseidon Robotics' Mini-HPU and unlock a world of possibilities for your subsea operations. Contact us today and witness the next level of subsea performance with the Mini-HPU by your side.

Buy

In Stock

Manufacturer

New

ASME

Air Freight

![]() Canaweld Inc. in Vaughan

Canaweld Inc. in Vaughan

Unleash the Power of Versatility with the Stickwelder 162 D! At Canaweld, we understand the diverse welding needs of the construction, oil & gas industries, and more. That's why we are thrilled to introduce the Stickwelder 162 D - a welding marvel that offers high-quality performance across a wide range of metals and thicknesses, ensuring impeccable results in every project. Portable Powerhouse The Stickwelder 162 D is designed to be your reliable companion, offering portability, power, and versatility in one compact unit. Whether you require Stick Welding or TIG welding with a lift start, this welding machine rises to the occasion, delivering consistent and exceptional welds. Safety and Efficiency Combined We understand the challenges of adverse conditions, which is why we've equipped the Stickwelder 162 D with an extra function that reduces power draw, ensuring safer and more efficient performance in challenging environments. When precision matters, trust the Stickwelder 162 D to get the job done. Ideal for Light to Medium Duty Projects From construction sites to oil & gas projects, the Stickwelder 162 D is the ideal choice for light to medium-duty projects, providing reliability and flexibility in all weather conditions. Its lightweight construction and convenient carrying belt make transportation a breeze, ensuring you can take this welding powerhouse wherever the job demands. Weld with Confidence Enjoy excellent arc characteristics with the most common rods up to 5/32 inches, providing you with the confidence to tackle a variety of welding tasks. Experience low power consumption, making it energy-efficient and eco-friendly. Ready for the Outdoors The Stickwelder 162 D is designed to work outdoors with the appropriate power generator, offering you the freedom to take on welding projects wherever they may be. It's fan-cooled and thermally protected, ensuring durability and performance even in demanding conditions. The Canaweld Promise With Canaweld's Stickwelder 162 D, you can rely on the Canaweld promise of excellence and durability. Our comprehensive 3-year warranty further solidifies our commitment to quality and customer satisfaction. Get the job done right with the Stickwelder 162 D. Embrace the power of versatility, portability, and efficiency, and elevate your welding experience with Canaweld. Whether you're on a construction site or in the oil & gas industry, trust the Stickwelder 162 D to deliver flawless welds. Choose the welding machine designed with your needs in mind - the Stickwelder 162 D. Welding Perfected!

Buy

In Stock

Manufacturer

New

ASME

Land Freight

.png)

![]() AMS Hydro in Vancouver

AMS Hydro in Vancouver

Designed for telecom applications; excellent ‘floor space savers’ for marine and vehicle applications The deep cycle AGM telecom series has been designed for use in telecom systems. With front access terminals and small footprint, the batteries are ideal for racked systems. Similarly, these batteries can help solve limited floor space and access problems on board boats and vehicles. AGM technology AGM stands for Absorbent Glass Mat. In these batteries the electrolyte is absorbed into a glass-fibre mat between the plates by capillary action. Low self-discharge Because of the use of lead calcium grids and high purity materials, Victron VRLA batteries can be stored during long periods of time without recharge. The rate of self-discharge is less than 2% per month at 20°C. The selfdischarge doubles for every increase in temperature by 10°C. Low internal resistance Accepts very high charge and discharge rates. High cyclic life capability More than 500 cycles at 50% depth of discharge. *data sourced from manufacturer.

Buy

Made to Order

Product

New

ASME

Sea Freight

Capacitance Discharge Stud Welder CAD 101

CD Stud Welder![]() Canaweld Inc. in Vaughan

Canaweld Inc. in Vaughan

Revolutionize Your Welding Experience with the Canaweld CAD 101 Stud Welding System! When it comes to precision and efficiency in stud welding, the Canaweld CAD 101 is a true game-changer. Harnessing the cutting-edge technology of Capacitor Discharge (CD) stud welding, this welding system offers unparalleled speed, accuracy, and versatility, making it the ultimate choice for welders in the oil and gas industry. The Power of Precision - Capacitor Discharge Stud Welding With a direct-current arc from a capacitor and weld times as quick as 1 to 6 milliseconds, the Canaweld CAD 101 delivers precision like no other. You'll achieve flawless welds without burn-through on the opposite side, even with very thin metals. Ideal for smaller diameter studs and pins, as well as non-standard materials, this system ensures accuracy in every weld. Unmatched Welding Capacity - Ready for Any Task The Canaweld CAD 101 boasts a full 3/8” (M10) welding capacity, making it a powerhouse in the stud welding world. Its compact design enables benchtop or automated applications with Canaweld's auto feed welding head, providing unmatched flexibility and convenience. Plus, it's compatible with any of Canaweld's hand guns, ensuring seamless integration into your welding process. Innovation at Its Core - Advanced Microcontroller Equipped with a cutting-edge microcontroller, the CAD 101 is continually up to date, delivering the latest in stud welding technology. The 15-pin subminiature interface allows for remote triggering, ready signals, and reload circuitry, making automation a breeze. Experience welding efficiency like never before with the CAD 101's industry-leading capacitance-to-weight ratio. The Canaweld Advantage - Unrivaled Features Take a look at the exceptional features of the Canaweld CAD 101: • Weld Range: Accommodates US Stud Size #6 – 3/8”, Metric Stud Size (M3-M10), Stud diameter 0.125″ – 0.375″ • Input Power 1~115/230, 50/60Hz (internally switchable) • 162,000uf Capacitance for powerful and rapid welds • Portable and Lightweight: Weighing only 37 lbs., it's easy to transport and use on-site • Microprocessor Controlled: Ensures precise and consistent welding performance • Remote Triggering: Added convenience for seamless operation • 3.5” Color Display: Easy-to-read and user-friendly interface • Programmable Pre-sets: Save your preferred welding settings for quick access • Resettable Weld Counter: Monitor and track your welding progress • Stepless Voltage Control: Achieve optimal welding settings with ease • Safety Shutdown: Provides protection in case of internal faults • Chuck Saver: Prevents double firing for flawless welds Embrace the Future of Stud Welding with Canaweld CAD 101! At Canaweld, we strive to empower welders with innovative solutions that excel in performance and efficiency. The CAD 101 exemplifies our dedication to excellence and commitment to meeting your welding needs. Upgrade your welding experience and achieve unmatched precision with the Canaweld CAD 101 Stud Welding System. Elevate your welding game with Canaweld - Your Partner in Welding Excellence!

Buy

In Stock

Manufacturer

New

ASME

Land Freight

![]() CWB National Leasing in Winnipeg

CWB National Leasing in Winnipeg

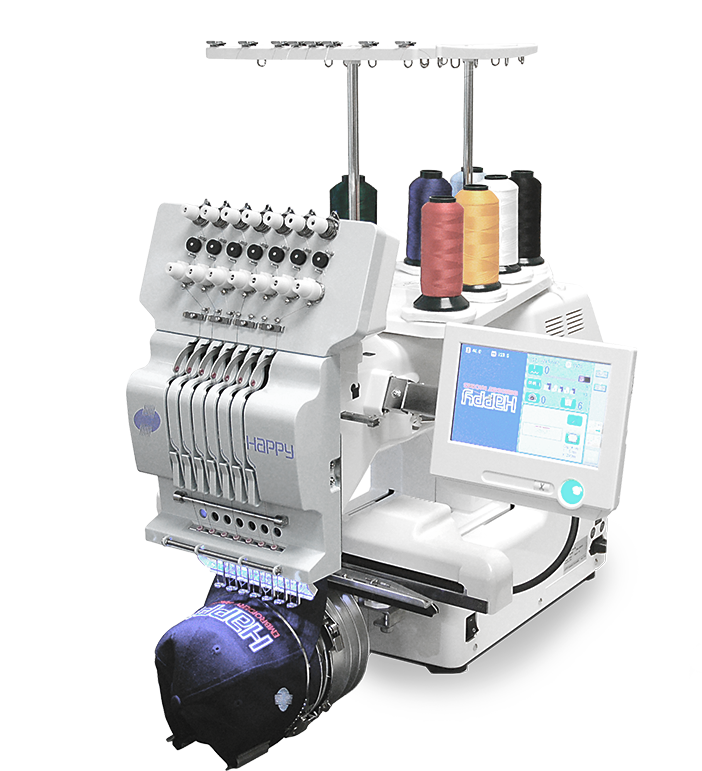

Elevate Your Textile Business with Embroidery Machine Leasing from CWB National Leasing Transforming Your Creative Ventures with Flexible and Cost-Effective Solutions In the dynamic world of textile and garment production, embroidery machines are pivotal for adding value and uniqueness to products. Leasing embroidery machines through Canadian Western Bank (CWB) National Leasing offers a strategic and financially astute solution for businesses looking to expand their embroidery capabilities. Here’s how leasing embroidery machines can enhance your textile business: 1. Rapid Equipment Access CWB National Leasing values the pace and efficiency of your business. They offer a fast and streamlined leasing process, with decisions typically made within 48 hours of application submission. This swift turnaround ensures that your embroidery machines can be delivered and operational quickly, keeping your production line active and efficient. 2. Enhanced Financial Flexibility Leasing embroidery machines with CWB National Leasing increases your purchasing power. Opting for periodic payments over a large upfront purchase helps free up capital for other crucial business operations. Additionally, the flexibility to add extra features or accessories to your machines for a small payment increase enables customization to meet your specific production requirements. 3. Effective Cash Flow Management With manageable lease payments spread over the term, your embroidery machines begin contributing to your business’s revenue while they are still being paid off. This approach helps maintain a healthy balance between expenses and revenue, which is essential for business growth and stability. 4. Customizable Payment Plans CWB National Leasing offers a variety of payment options, including seasonal, semi-annual, or annual plans, tailored to align with your business’s financial cycle. This flexibility is particularly beneficial for businesses with seasonal fluctuations in income, ensuring that payments are practical and aligned with your financial situation. 5. Potential Tax Advantages Leasing embroidery machines can offer tax benefits, such as the ability to expense lease payments instead of capitalizing the cost of the equipment. Consulting with a tax advisor is advisable to explore how leasing can positively impact your business’s tax position. Conclusion Choosing to lease embroidery machines through CWB National Leasing is a strategic decision that equips your textile business with advanced equipment while maintaining financial agility. It ensures access to state-of-the-art embroidery machines, vital for producing high-quality, detailed designs, without the financial burden of a large upfront investment. This leasing approach enables enhanced operational efficiency, increased production capacity, and greater profitability, helping your business to thrive in the competitive textile industry.

Service

In Stock

Service

New

ISO

![]() Canaweld Inc. in Vaughan

Canaweld Inc. in Vaughan

Introducing the Revolutionary MIG Gun M250 Series: Your Ultimate Welding Companion When it comes to heavy-duty, durable, and high-performance MIG guns, look no further than the Canaweld M250 Series. Crafted with precision and innovation, this newly designed MIG gun sets a new standard in the welding industry. Engineered to meet the demands of the oil and gas industry, the M250 Series will transform the way you weld, offering unmatched versatility, comfort, and efficiency. Built for Excellence - Unleash the Power of Adaptability The M250 MIG gun boasts a unique and cutting-edge feature that sets it apart from the rest - the ability to convert termination styles seamlessly. With a simple replacement, you can switch between Euro style, Lincoln® style, Tweco® style, or Miller® style, ensuring compatibility with various welding machines. This adaptability makes the M250 Series a true game-changer for welders, offering unmatched flexibility in their welding projects. Unrivaled Features - Mastering Welding Precision Let's dive into the exceptional features of the Canaweld M250 Series: 1. Knuckle Joint: Experience improved balance and position-ability as the handle and neck move independently of the cable assembly. Weld with greater precision and control. 2. Durable Cable: The M250 MIG gun boasts excellent heat, abrasion resistance, and flexibility in its cable. It's lighter than standard cable sets and can withstand over 1 million flexes in life testing, ensuring it stands the test of time. 3. Premium Contact Tips: Crafted from premium grade copper alloys, the contact tips are extremely durable, offering superior performance and efficiency. 4. High-Quality Accessories: Choose from a range of durable and high-performance options for tip adaptors, diffusers, and swan necks, tailoring your MIG gun to suit your specific needs. 5. Ergonomic Handle Design: Enjoy comfortable handling with the ergonomic design of the handle, reducing welder fatigue and promoting longer welding sessions. 6. Air Gap Technology: The M250 MIG gun utilizes air gap technology for cooler running handles and better heat transfer isolator from the swan neck, ensuring efficient and effective welding. 7. Versatile Liner: The steel and combo liner cater to all types of wires, including steel (metalcore and flux-cored), stainless steel (metalcore and flux-cored), and aluminum, making it suitable for a wide range of welding applications. 8. Effective Sealing: The unique sealing ring ensures effective sealing of impurities, particularly in the argon gas process, promoting cleaner welds. 9. Push-on Nozzle System: Easily adjust nozzle stick-out with the push-on nozzle system, streamlining your welding workflow. 10. High-Quality Trigger: The M250 MIG gun comes with a high-quality trigger that boasts a life expectancy of over 1 million cycles, offering durability and reliability in every weld. Elevate Your Welding Experience with Canaweld M250 Series At Canaweld, we strive to empower welders with the latest advancements in welding technology. The M250 Series is a testament to our commitment to excellence, providing welders with a powerful, versatile, and comfortable welding solution. Experience the future of welding with the Canaweld M250 Series - Your Ultimate Welding Companion!

Buy

In Stock

Manufacturer

New

ASME

Land Freight

Crew Transport using modern buses worldwide

Crew Bus![]() Feldman Transport in Red Deer

Feldman Transport in Red Deer

Crew Transport buses for long term charter in locations around the world where reliable transportation is critical. Getting the crew to and from the job site in safety and comfort is key to a good start and end to the workday. Custom crew bus solutions available and every project is unique so please contact us to work together to find an optimum solution on crew transport.

Rental

Currently in Use

Product

New

ISO

Land Freight

![]() Canaweld Inc. in Vaughan

Canaweld Inc. in Vaughan

Introducing the Canaweld CAD 81 Capacitor Discharge Stud Welding System: Power and Precision Unleashed! When it comes to high-performance stud welding, the Canaweld CAD 81 stands in a league of its own. Harnessing the cutting-edge technology of Capacitor Discharge (CD) stud welding, this welding system offers unparalleled precision, speed, and efficiency, making it the ultimate choice for welders in the oil and gas industry. Precision in a Blink - Capacitor Discharge Stud Welding The Canaweld CAD 81 utilizes a direct-current arc from a capacitor, allowing for weld times as quick as 1 to 6 milliseconds. The result? Seamlessly welded studs with no burn-through on the opposite side, even with very thin metals. Perfect for smaller diameter studs, pins, non-standard materials, and when precision is paramount. Compact Yet Powerful - Unmatched Welding Capacity Don't be fooled by its compact design; the Canaweld CAD 81 boasts a full 5/16-inch (M8) welding capacity, making it the most compact and versatile system on the market. Its microprocessor control ensures precise and consistent welding performance, while the enhanced charging circuit with a high output transformer maximizes its duty cycle, offering you unmatched welding power in a lightweight package. Safety and Ease of Use - User-Friendly and Efficient The Canaweld CAD 81 is designed with your safety and convenience in mind. With enhanced user feedback, including safety and fault codes, you can weld with confidence and peace of mind. The system comes complete with everything you need, including the gun, two ground cables, collets, changing tools, and a convenient carrying case for easy transportation. Features That Make a Difference Let's take a look at some of the remarkable features of the Canaweld CAD 81: • Weld Range: Accommodates US Stud Size #4 – 5/16”, Metric Stud Size (M3-M8), Stud diameter 0.112″ – 0.312″ • Input Power 1~115/230, 50/60Hz (internally switchable) • 81,000uf Capacitance for rapid and powerful welds • Portable and Lightweight: Weighing only 25 lbs., take it anywhere the job demands • Ergonomic Design: Designed for comfort and ease of use during extended welding sessions • Heavy-Duty Cable Set: Ensures robust and reliable connections • Dual Ground Cable: For added safety and efficiency • Fully Adjustable Leg Set: Achieve the perfect welding angle for every job • Diagnostic LEDs: Easy troubleshooting and maintenance The Canaweld CAD 81 - Empowering Welders in the Oil and Gas Industry At Canaweld, we take pride in providing cutting-edge welding machines and accessories that meet the unique demands of the oil and gas industry. The CAD 81 exemplifies our commitment to excellence, innovation, and your welding success. Unleash the Power of Precision and Performance with the Canaweld CAD 81 Capacitor Discharge Stud Welding System. Empower your welding journey with Canaweld - Your Partner in Welding Excellence!

Buy

In Stock

Manufacturer

New

ASME

Land Freight

![]() KEY360 Inc in New York, NY

KEY360 Inc in New York, NY

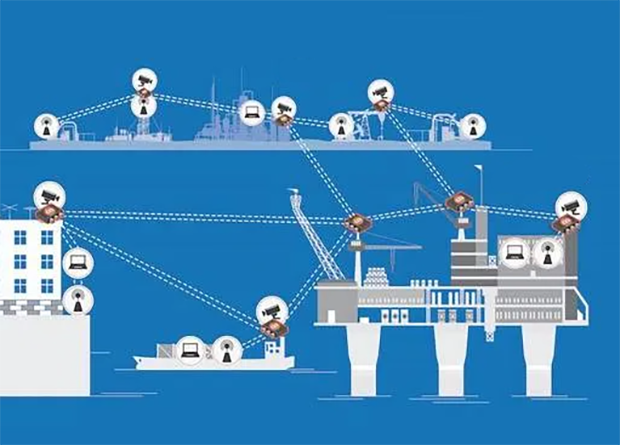

KEY360 Inc offers a single integrated Business Management Platform comprising Business Intelligence, Project Management, Big Data & Analytics, ERP, Behaviour and Strategy Modification. - Over 140 Business and Project Management Systems on one platform available - Unique and extremely effective workflow engine - Remarkable “BIG DATA” and bulk transaction capability - Integrated Real Time reporting and dashboarding - Multi-company platform allows all project users to integrate seamlessly KEY Differentiators: - KEY360 Provides an exceptional opportunity for your organisation to attract new clients and build long terms relationships. - KEY360 is a Microsoft Gold Partner and Approved Microsoft Co-Sell Partner and can be purchased directly from the below online marketplaces: - Microsoft AppSource: KEY360 Capital Management Projects - Azure Marketplace: KEY360 Capital Management Projects - KEY360 is reputedly the most comprehensive and versatile Capital Project Management, Business Digitalization & Business Optimization solution available.

Service

In Stock

Service

New

ISO

Safe-T-Whip RD or “Regular Duty”