Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

Don't have an account? Join for free

For advertising on

Interest to become a seller? Get info

New here? Sign up

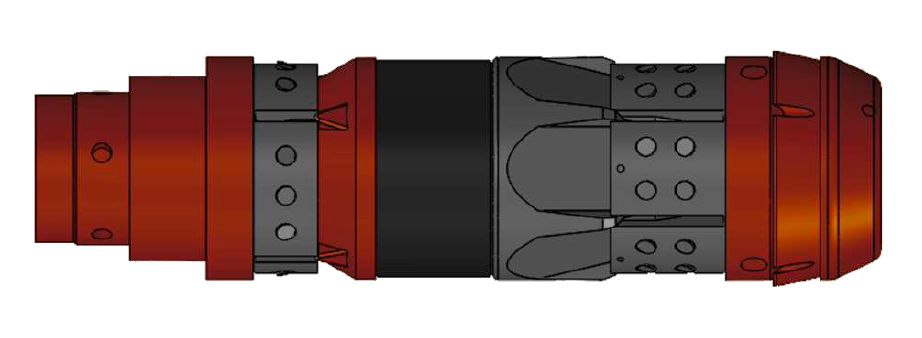

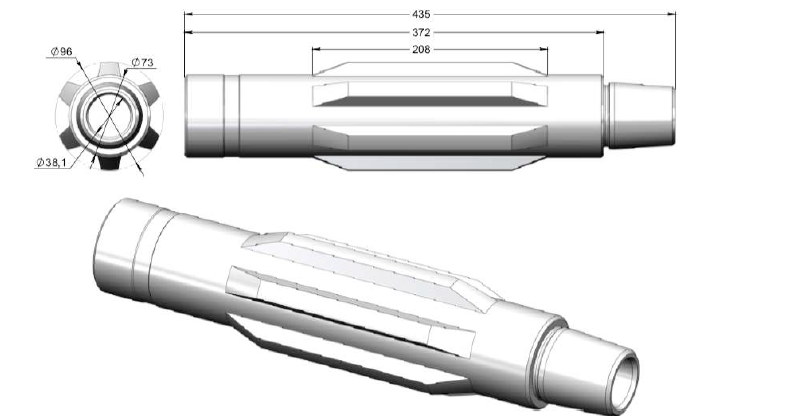

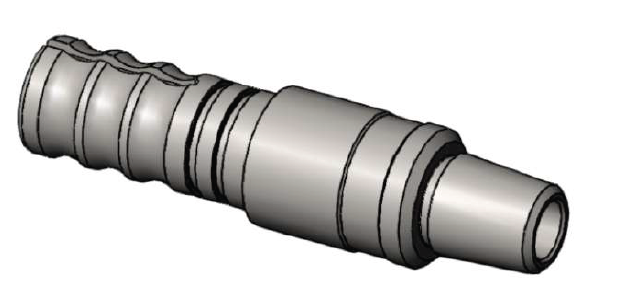

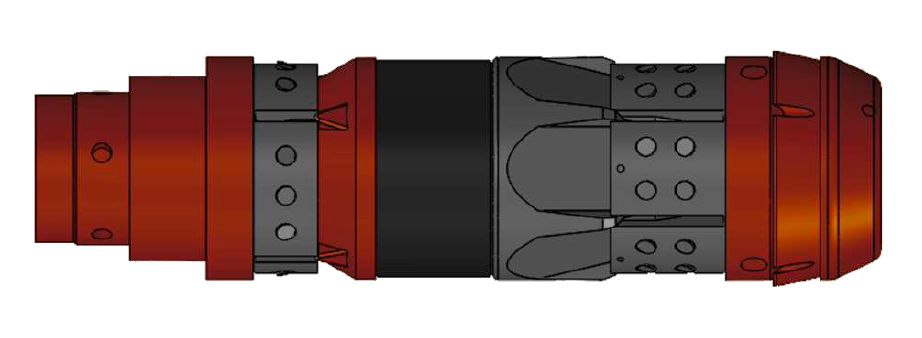

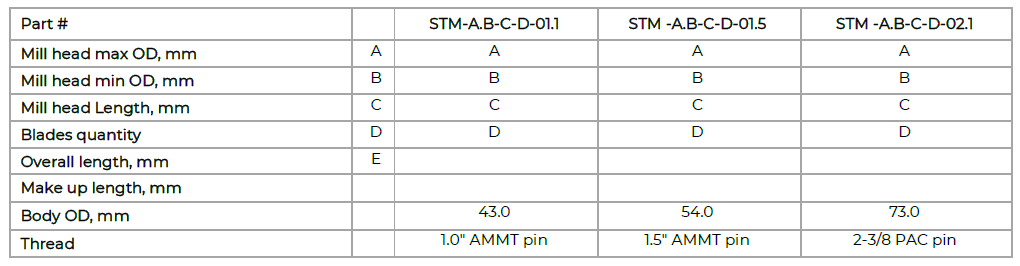

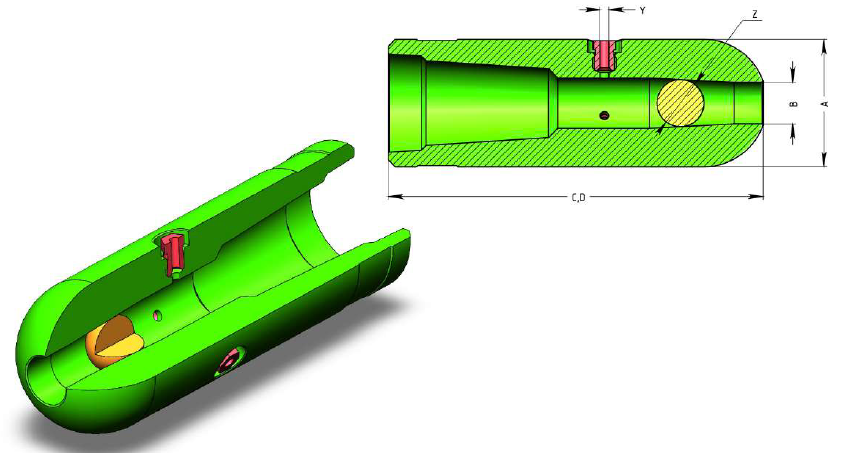

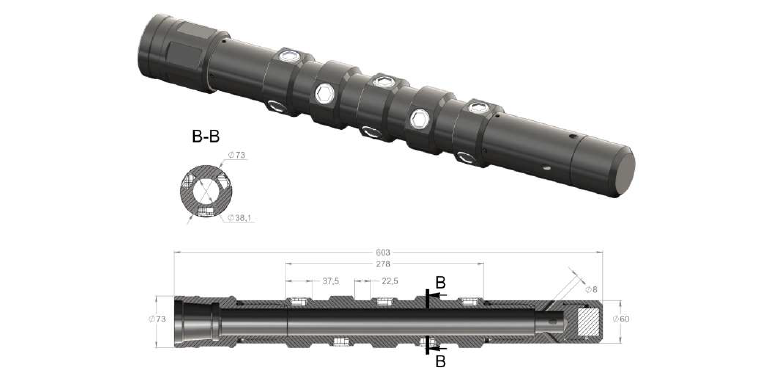

STM Step Mill

Also known as:

Coiled Tubing Downhole Tool, BHABuy

Made to Order

Manufacturer

New

API

Land Freight

Title:

Step MillModel Number:

STM-A.B-C-D-01.1Availability:

Made to OrderDelivery Time (weeks):

2 - 4 WeeksIn Stock

Transaction Type

BuyCondition

NewWeight

Based on Specs lbsLocation

CanadaCompany Type

ManufacturerQuality Assurance

APIPrice

Request for QuoteMaterial

SteelBrand Name

Marlin Oil ToolsShipping

Land FreightNotes

Step mill used for increasing ID of the restrictions in the well but compare to Tapered mill, it has less friction surface which allows to mill out more harder materials and apply higher weight on bit without stalling the downhole motor.

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools: The Premier Solution for Well Cleaning and Debris Removal in the Oil and Gas Industry Marlin Oil Tools is proud to unveil the MGN Flat Bottom Downhole Magnet, a specialized downhole tool engineered to address the critical need for thorough well cleaning in oil and gas operations. Designed to efficiently remove small metal debris, such as chips and scale, the MGN Flat Bottom Downhole Magnet is essential for maintaining the integrity and operational efficiency of wells. With its unique flat bottom design and internal passage for simultaneous flushing, this tool is a game-changer for well work preparation. Key Features of the MGN Flat Bottom Downhole Magnet: Optimized Debris Removal: The flat bottom design enhances the magnet's ability to capture and remove metal debris from the well, ensuring a cleaner wellbore environment. Simultaneous Well Flushing: Features an internal passage hole, allowing for well flushing during magnet operation, thereby maximizing cleaning efficiency and reducing downtime. Versatile Design: Capable of accommodating various well conditions with a magnetic surface that can be located along the tool body or from the end, offering flexibility in application. Customizable Connections: Marlin Oil Tools provides customizable connecting threads to ensure seamless integration with your existing downhole tool configurations. Prevention of Complications: By removing foreign metal objects and debris, the MGN Flat Bottom Downhole Magnet minimizes the potential for operational complications and accidents. Essential for Well Maintenance: Acts as a crucial step in well work preparation, helping to clear the way for further well intervention and maintenance activities. Elevate your well intervention and maintenance strategies with the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools, a leading-edge solution for effective well cleaning in the oil and gas sector. This downhole magnet is specifically designed to remove metal debris, ensuring well integrity and operational efficiency. With its unique flat bottom design and internal flushing capability, the MGN Flat Bottom Downhole Magnet stands out as an essential tool for any well work preparation, offering customizable connections for a perfect fit with your operations. Choose Marlin Oil Tools for reliable, efficient, and versatile well cleaning solutions. Why Choose the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools? Superior Cleaning Efficiency: Designed to effectively capture and remove a wide range of metal debris from wells. Operational Versatility: Adapts to various well conditions and integrates seamlessly with your BHA for comprehensive cleaning. Enhanced Safety Measures: By clearing metal debris, it significantly reduces the risk of downhole complications and accidents. Customization Options: Offers tailor-made connecting threads to fit your specific operational requirements and tool setups. The MGN Flat Bottom Downhole Magnet by Marlin Oil Tools represents the forefront of downhole cleaning technology, providing operators with a robust tool for enhancing well performance and safety. Incorporate the MGN Flat Bottom Downhole Magnet into your well maintenance protocols to achieve cleaner, safer, and more efficient well operations.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Grub Screw Connector Preparation Tool

GPT, Grub screw connector Preparation Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the GPT Grub Screw Connector Preparation Tool from Marlin Oil Tools: Your Essential Partner for Coil Tubing Operations Marlin Oil Tools is proud to present the GPT Grub Screw Connector Preparation Tool, a meticulously designed hand tool engineered to streamline the process of making up and removing grub screw connectors at the coil tubing end. This tool is an indispensable asset for oil and gas field operations, offering unmatched reliability and convenience for technicians and engineers alike. Key Features of the GPT Grub Screw Connector Preparation Tool: Reliable Design: The GPT features a robust construction that includes a dimple block, back hammer, and thread box, ensuring durable and dependable operation under field conditions. Efficient Operation: Designed for quick and convenient mounting or disassembly of grub screw connectors on coil tubing, the GPT enhances operational efficiency and reduces downtime. Ease of Use: As a hand tool, the GPT is engineered for ease of use in the field, enabling technicians to perform connector changes swiftly and with minimal effort. Versatile Compatibility: Suitable for a wide range of grub screw connector types and sizes, the GPT is a versatile tool that meets the diverse needs of coil tubing operations. Durable Construction: Built to withstand the rigors of oil and gas field use, the GPT promises long service life and consistent performance across countless operations. Optimized for Field Conditions: With its compact and user-friendly design, the GPT is optimized for use in various field conditions, ensuring reliability when it matters most. Elevate your coil tubing operations with the GPT Grub Screw Connector Preparation Tool from Marlin Oil Tools, a leading-edge solution designed for the efficient management of grub screw connectors in the oil and gas industry. The GPT combines a reliable design with user-friendly features, including a dimple block, back hammer, and thread box, to facilitate quick and convenient connector changes. Ideal for field technicians seeking to enhance operational efficiency, the GPT offers ease of use, durable construction, and versatile compatibility with various connector types and sizes. Opt for Marlin Oil Tools’ GPT Grub Screw Connector Preparation Tool for streamlined connector preparation and removal, ensuring smooth and efficient coil tubing operations. Why Choose the GPT Grub Screw Connector Preparation Tool from Marlin Oil Tools? Streamlined Connector Changes: Simplifies the process of making up and removing connectors, enhancing workflow efficiency. Field-Ready Design: Offers a compact and robust design tailored for the demands of oil and gas field operations. User-Centric Operation: Designed as a hand tool for maximum ease of use and operational convenience. Long-Term Reliability: Engineered with durable materials to ensure longevity and consistent performance in challenging environments. The GPT Grub Screw Connector Preparation Tool by Marlin Oil Tools represents the pinnacle of innovation in coil tubing equipment, providing a practical, efficient, and reliable solution for connector management in the field. Incorporate the GPT into your toolkit for enhanced operational efficiency and convenience in all your coil tubing endeavors.

Buy

Made to Order

Manufacturer

New

API

Land Freight

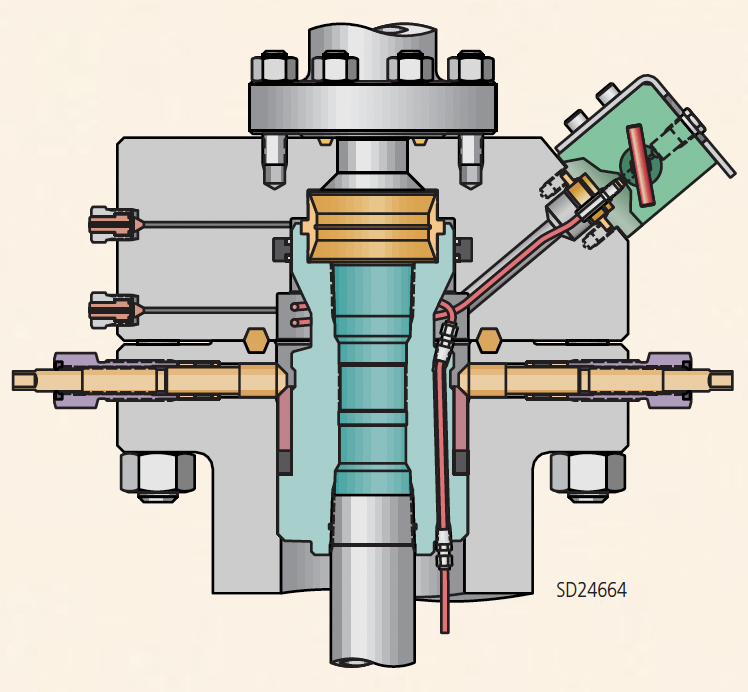

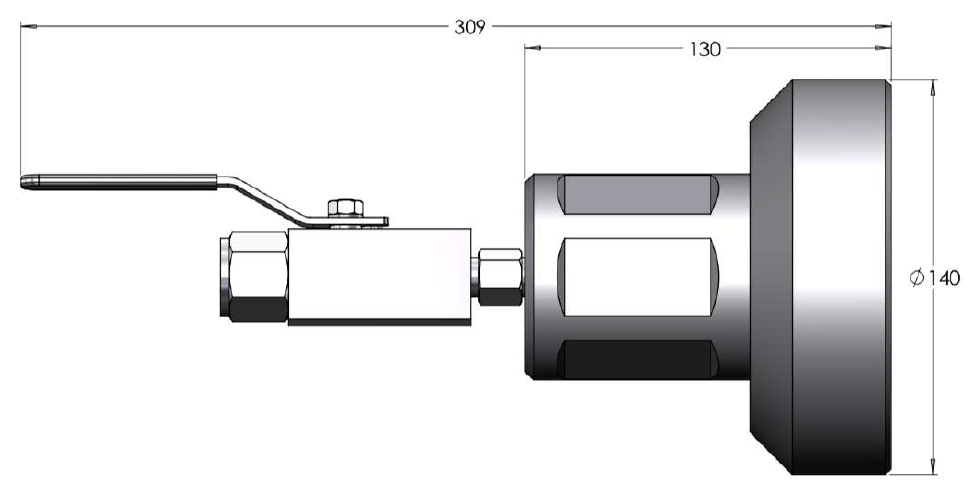

Coiled Tubing Hydraulic Setting Tool

SST Hydraulic Setting Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the SST Hydraulic Setting Tool from Marlin Oil Tools: The Ultimate Mechanical Solution for Downhole Equipment Setting Marlin Oil Tools is proud to present the SST Hydraulic Setting Tool, a fully mechanical downhole tool engineered to revolutionize the setting of bridge plugs and cement retainers within the well casing. Designed for versatility, the SST can be deployed via coil tubing or traditional tubing, making it a crucial component for enhancing well integrity and operational efficiency in oil and gas interventions. Key Features of the SST Hydraulic Setting Tool: Versatile Application: Compatible with both coil tubing and traditional tubing, offering flexible deployment options for various well intervention scenarios. Mechanical Activation: Utilizes a simple yet effective mechanical activation process, where a ball landing in the piston initiates the setting mechanism. Precise Setting Capability: Provides accurate and reliable setting of bridge plugs and cement retainers, crucial for wellbore stability and integrity. High-Pressure Performance: Engineered to withstand the shear pressure required to move the piston and secure the downhole equipment in place. Optimized for Well Interventions: Enhances the efficiency and safety of well interventions by ensuring the precise placement of downhole tools. Ease of Operation: The straightforward mechanical design ensures ease of use, minimizing potential operational complications. Elevate your well intervention and completion processes with the SST Hydraulic Setting Tool from Marlin Oil Tools, a premier mechanical solution designed for the oil and gas industry. This innovative tool simplifies the setting of bridge plugs and cement retainers, ensuring optimal well casing integrity. Compatible with both coil tubing and traditional tubing, the SST offers unparalleled versatility and reliability. With its mechanical activation mechanism and high-pressure performance, the SST Hydraulic Setting Tool is essential for achieving precise downhole equipment placement, enhancing operational efficiency and well integrity. Choose the SST for a streamlined, effective approach to well interventions. Why Choose the SST Hydraulic Setting Tool from Marlin Oil Tools? Flexible Deployment Options: Ensures compatibility with various intervention methods, increasing tool utility. Reliable Mechanical Activation: Simplifies the setting process, reducing the risk of operational errors. Precision in Downhole Settings: Guarantees the accurate placement of bridge plugs and cement retainers for improved well performance. Durability Under Pressure: Built to endure the rigorous conditions of downhole operations, offering lasting performance. The SST Hydraulic Setting Tool by Marlin Oil Tools represents the cutting edge in downhole mechanical solutions, providing operators with a powerful tool for enhancing well completion and intervention outcomes. Incorporate the SST into your operations to ensure efficient, accurate, and reliable downhole equipment setting.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

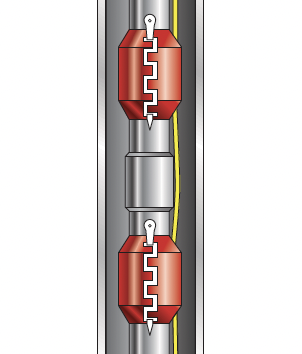

Introducing the CBP Composite Bridge Plug from Marlin Oil Tools: The Cutting-Edge Solution for Temporary Well Barrier Operations Marlin Oil Tools is proud to present the CBP Composite Bridge Plug, a state-of-the-art downhole tool designed for optimal performance in oil and gas well operations. Engineered for easy installation using a hydraulic Setting Tool (STT), the CBP Composite Bridge Plug provides an effective temporary barrier within the well, isolating underlying intervals for enhanced operational control and safety. Key Features of the CBP Composite Bridge Plug: Efficient Installation: Utilizes a hydraulic Setting Tool (STT) for quick and secure deployment in oil and gas wells. Reliable Well Isolation: Designed to create a temporary barrier, effectively cutting off underlying intervals to manage wellbore integrity. Easy Removal Process: The composite bridge plug can be easily milled away using standard milling BHA, facilitating straightforward removal. Durable and Reliable Construction: Features collets with an easily drilled design, made from high-quality composite materials and reinforced with ceramic cylinders for increased durability. Proven Field Performance: The reliability and effectiveness of the CBP Composite Bridge Plug have been validated through extensive field work, ensuring dependable well isolation. Maximize your well intervention and maintenance operations with the CBP Composite Bridge Plug from Marlin Oil Tools, a premier solution for establishing temporary barriers in oil and gas wells. Engineered with advanced composite materials and ceramic cylinders, the CBP offers unmatched reliability and ease of installation using a hydraulic Setting Tool (STT). Whether you need to isolate wellbore intervals or ensure operational safety, the CBP Composite Bridge Plug's field-proven technology and easy milling process make it an indispensable tool for modern well operations. Choose the CBP for efficient, reliable, and easy-to-remove wellbore isolation. Why Choose the CBP Composite Bridge Plug from Marlin Oil Tools? Superior Wellbore Isolation: Offers effective temporary isolation, improving operational safety and control. Streamlined Installation and Removal: Designed for ease of installation and removal, reducing downtime and operational costs. Advanced Material Construction: Utilizes composite materials and ceramic cylinders for enhanced durability and reliability. Field-Tested Technology: Backed by extensive field testing, ensuring proven performance in various well conditions. The CBP Composite Bridge Plug by Marlin Oil Tools represents the forefront of downhole tool innovation, providing oil and gas operators with a reliable, efficient solution for temporary wellbore isolation. Incorporate the CBP into your operations to benefit from its superior performance and ease of use.

Buy

Made to Order

Manufacturer

New

API

Land Freight

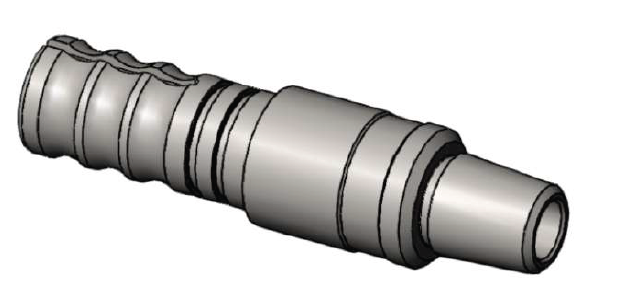

Internal Dimple Connector for Coiled Tubing

IDC Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the IDC (Internal Dimple Connector) by Marlin Oil Tools: The Premier Solution for Secure Coiled Tubing Connections in Oil and Gas Well Interventions Marlin Oil Tools proudly unveils the IDC (Internal Dimple Connector), a breakthrough in coiled tubing connector technology, engineered to provide a seamless and secure connection between the smooth lower end of coiled tubing (CT) and various downhole tools essential for effective well intervention operations. Optimized for the oil and gas industry, the IDC ensures a robust link, enhancing operational efficiency and safety. Discover the unparalleled benefits of incorporating the IDC into your well intervention toolkit. Key Features of the IDC (Internal Dimple Connector): Optimized Connection Design: The IDC features innovative spherical recesses in its upper part, designed specifically for the precise and secure fixing of coiled tubing through mechanical or hydraulic pressing. This design ensures a tight and reliable connection, crucial for the demanding environments of well intervention jobs. Threaded Lower Part for Tool Attachment: The connector’s lower section is equipped with a thread to facilitate the easy attachment of downhole tools. This feature allows for a versatile use of the IDC across a wide range of well intervention activities, making it a staple in any operation. Enhanced Sealing with FKM 90 O-rings: Equipped with two O-rings made from the durable FKM 90 material, the IDC offers superior sealing capabilities. This design effectively isolates the internal space of the connector and the annulus, preventing fluid leakage and ensuring the integrity of well operations. Easy and Efficient Installation: The installation of the IDC is streamlined and efficient, compatible with dimple tools for both mechanical and hydraulic pressing. This ease of installation reduces operational downtime, enabling quicker transitions between tasks and enhancing overall productivity. Elevate your well intervention operations with the IDC (Internal Dimple Connector) from Marlin Oil Tools, a leading solution for coiled tubing applications in the oil and gas industry. Designed to securely link the smooth lower end of coiled tubing to downhole tools, the IDC features advanced spherical recesses for a reliable connection and a threaded lower part for easy tool attachment. With dual O-rings made from high-quality FKM 90 material, it offers exceptional sealing, protecting your operations from fluid leakage. Ideal for a variety of well intervention jobs, the IDC is engineered for easy installation with mechanical or hydraulic pressing, ensuring operational efficiency and safety. Choose the IDC for a trusted connection in your coiled tubing operations. Why Choose the IDC from Marlin Oil Tools? Reliability: Engineered for the harsh conditions of downhole operations, the IDC provides a secure and reliable connection, minimizing the risk of disconnections or failures during critical well intervention tasks. Versatility: The threaded lower part of the IDC makes it compatible with a broad array of downhole tools, offering unparalleled flexibility in well intervention operations. Operational Efficiency: Designed for quick and easy installation, the IDC reduces downtime and increases the efficiency of well intervention activities. Safety and Integrity: With its superior sealing capabilities, the IDC enhances the safety and integrity of well operations, ensuring a leak-free connection. Marlin Oil Tools is committed to advancing the efficiency and safety of oil and gas operations with innovative solutions like the IDC (Internal Dimple Connector). Contact us today to learn how our cutting-edge coiled tubing tools can optimize your well intervention strategies.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the STM Step Mill from Marlin Oil Tools: Your Go-To Solution for Advanced Well Intervention and Milling Operations Marlin Oil Tools is excited to offer the STM Step Mill, a cutting-edge downhole tool specifically designed to enhance the efficiency of well intervention jobs. Whether you're dealing with bridge plugs, emergency lost equipment, or any obstruction softer than the mill's cutter, the STM Step Mill is engineered to grind and wash out these objects with unmatched efficiency. Key Features of the STM Step Mill: Superior Milling Performance: Designed to navigate and mill through downhole obstructions effectively, ensuring a clear wellbore for optimal production. Reduced Friction Surface: The STM Step Mill features a unique design with less friction surface, enabling it to mill out harder materials more efficiently than traditional tapered mills. Enhanced Weight-on-Bit Application: Its innovative design allows for higher weight on bit without the risk of stalling the downhole motor, maximizing milling effectiveness. Optimal Debris Removal: Equipped with multiple flushing holes, the STM ensures the efficient circulation of drilling fluid to remove milled particles from the well and cool the cutting edge. Durable Carbide Construction: Built with carbide welded onto the body, including options for crushed carbide and various insert designs, the STM Step Mill is designed for longevity and performance in challenging milling conditions. Comprehensive Redress Services: Marlin Oil Tools offers redress services for worn carbide, ensuring your STM Step Mill maintains peak performance throughout its service life. Elevate your well intervention strategies with the STM Step Mill from Marlin Oil Tools, a premier downhole tool designed for the oil and gas industry. Tailored for efficient grinding and removal of downhole obstructions, the STM Step Mill stands out with its reduced friction surface and ability to tackle harder materials without stalling the downhole motor. With its advanced carbide construction, optimal debris removal capabilities, and customizable insert options, the STM Step Mill is the ideal choice for increasing the ID of well restrictions and ensuring smooth wellbore conditions. Opt for Marlin Oil Tools’ STM Step Mill for enhanced well intervention and milling operations, backed by comprehensive redress services to extend tool life and performance. Why Choose the STM Step Mill from Marlin Oil Tools? Advanced Milling Efficiency: Offers unmatched efficiency in grinding down wellbore obstructions. Capability to Mill Harder Materials: Designed to tackle harder materials with greater ease compared to conventional mills. Higher Weight-on-Bit Flexibility: Enhances milling operations by allowing higher weight on bit without compromising tool performance. Customization and Longevity: Provides various carbide insert designs and redress services, ensuring a long service life tailored to your specific operational needs. The STM Step Mill by Marlin Oil Tools represents the forefront of downhole milling technology, offering a powerful solution for oil and gas operators focused on optimizing well intervention outcomes. Incorporate the STM Step Mill into your operations for smoother, more efficient wellbore preparation and obstacle management.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools: The Premier Solution for Well Cleaning and Debris Removal in the Oil and Gas Industry Marlin Oil Tools is proud to unveil the MGN Flat Bottom Downhole Magnet, a specialized downhole tool engineered to address the critical need for thorough well cleaning in oil and gas operations. Designed to efficiently remove small metal debris, such as chips and scale, the MGN Flat Bottom Downhole Magnet is essential for maintaining the integrity and operational efficiency of wells. With its unique flat bottom design and internal passage for simultaneous flushing, this tool is a game-changer for well work preparation. Key Features of the MGN Flat Bottom Downhole Magnet: Optimized Debris Removal: The flat bottom design enhances the magnet's ability to capture and remove metal debris from the well, ensuring a cleaner wellbore environment. Simultaneous Well Flushing: Features an internal passage hole, allowing for well flushing during magnet operation, thereby maximizing cleaning efficiency and reducing downtime. Versatile Design: Capable of accommodating various well conditions with a magnetic surface that can be located along the tool body or from the end, offering flexibility in application. Customizable Connections: Marlin Oil Tools provides customizable connecting threads to ensure seamless integration with your existing downhole tool configurations. Prevention of Complications: By removing foreign metal objects and debris, the MGN Flat Bottom Downhole Magnet minimizes the potential for operational complications and accidents. Essential for Well Maintenance: Acts as a crucial step in well work preparation, helping to clear the way for further well intervention and maintenance activities. Elevate your well intervention and maintenance strategies with the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools, a leading-edge solution for effective well cleaning in the oil and gas sector. This downhole magnet is specifically designed to remove metal debris, ensuring well integrity and operational efficiency. With its unique flat bottom design and internal flushing capability, the MGN Flat Bottom Downhole Magnet stands out as an essential tool for any well work preparation, offering customizable connections for a perfect fit with your operations. Choose Marlin Oil Tools for reliable, efficient, and versatile well cleaning solutions. Why Choose the MGN Flat Bottom Downhole Magnet from Marlin Oil Tools? Superior Cleaning Efficiency: Designed to effectively capture and remove a wide range of metal debris from wells. Operational Versatility: Adapts to various well conditions and integrates seamlessly with your BHA for comprehensive cleaning. Enhanced Safety Measures: By clearing metal debris, it significantly reduces the risk of downhole complications and accidents. Customization Options: Offers tailor-made connecting threads to fit your specific operational requirements and tool setups. The MGN Flat Bottom Downhole Magnet by Marlin Oil Tools represents the forefront of downhole cleaning technology, providing operators with a robust tool for enhancing well performance and safety. Incorporate the MGN Flat Bottom Downhole Magnet into your well maintenance protocols to achieve cleaner, safer, and more efficient well operations.

Buy

Made to Order

Manufacturer

New

API

Land Freight

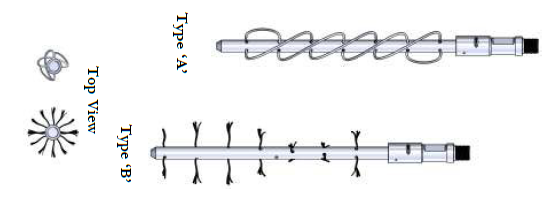

Fixed Blade Stabilizer for Coiled Tubing

FBS Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the FBS (Fixed Blade Stabilizer) from Marlin Oil Tools: The Optimal Solution for Coiled Tubing Stability in Oil and Gas Well Interventions Marlin Oil Tools proudly presents the FBS (Fixed Blade Stabilizer), a cutting-edge downhole tool meticulously designed to enhance the stability and efficiency of well intervention operations. As part of the borehole assembly (BHA), the FBS plays a crucial role in centering the BHA relative to the well's axis, ensuring optimal performance during critical interventions, especially in wells with significant inclination or when coiled tubing (CT) exhibits residual bending. Here’s why the FBS is an indispensable tool for your operations. Key Features of the FBS (Fixed Blade Stabilizer): Precision Centering: Engineered to center the BHA within the well, the FBS ensures that tools like mills or perforators operate effectively at the heart of the wellbore, crucial for tasks requiring precise positioning such as milling or perforation. Versatile Application: Ideal for use in wells with various inclinations, up to 90 degrees, where the BHA tends to lie against the well wall, the FBS provides the necessary support to maintain the BHA in the optimal position. Enhanced Stability: By preventing the eccentric location of the CT BHA within the well, the FBS significantly reduces the risk of operational issues, ensuring smoother, more efficient well interventions. Robust Design: The fixed blades of the FBS are designed to withstand the harsh downhole conditions, offering durability and reliability throughout the operation. Elevate your well intervention strategies with the FBS (Fixed Blade Stabilizer) from Marlin Oil Tools, a premier downhole tool designed for maximum BHA stability and efficiency in oil and gas operations. The FBS excels in centering the BHA relative to the well's axis, ensuring accurate positioning for milling, perforation, and other precision-dependent tasks. With its ability to accommodate wells of up to 90 degrees inclination and correct CT BHA eccentricity, the FBS is your solution for enhancing operational effectiveness and reducing risks in challenging well conditions. Choose the FBS for unparalleled support and stability in your coiled tubing operations. Why Choose the FBS from Marlin Oil Tools? Optimized Well Intervention: Improves the accuracy and efficiency of milling and perforation tasks by centering the BHA. Adaptable to Various Well Inclinations: Provides consistent performance in wells with up to 90 degrees of inclination. Reliable Stability: Reduces operational complications by preventing the CT BHA from lying eccentrically in the well. Durable Construction: Built to endure the rigors of downhole environments, ensuring longevity and reliability. The FBS (Fixed Blade Stabilizer) by Marlin Oil Tools represents the forefront of downhole stabilization technology, ensuring that your well intervention operations are performed with the highest level of precision and efficiency. Incorporate the FBS into your coiled tubing operations to achieve optimal outcomes in well stability and intervention success.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the LIB Lead Impression Block from Marlin Oil Tools: The Precision Tool for Effective Downhole Fishing Operations Marlin Oil Tools proudly presents the LIB Lead Impression Block, a specialized downhole tool designed to enhance the efficiency and accuracy of fishing operations within oil and gas wells. Engineered with a lead lower part, the LIB is adept at making precise impressions of downhole obstructions, commonly referred to as "fish," enabling operators to identify the type of obstruction and select the most suitable fishing tool for retrieval. Key Features of the LIB Lead Impression Block: Precision Impression Capability: The lead lower part of the LIB captures detailed prints of downhole obstructions, facilitating accurate identification of the fish. Customizable Design: Tailored to specific operational needs, the LIB offers customizable options for the body shape, size, and lead coating, as well as the presence and direction of flushing holes. Efficient Sediment Clearance: Equipped with a central flushing hole directed downwards, the LIB can clear sediments from the top of the fish before making an impression, ensuring a clean and clear print. Optimized for Single Use: Designed for optimal performance in a single run, with Marlin Oil Tools providing redress services for the lead layer to ensure the tool's readiness for future operations. Adaptable to Various Well Conditions: The versatility in design allows the LIB to be adapted for different well geometries and conditions, enhancing its utility across a wide range of fishing scenarios. Streamlined Fishing Operations: By providing a clear impression of the obstruction, the LIB aids in the selection of the most effective fishing tool, streamlining the retrieval process and reducing operational downtime. Elevate your well intervention and fishing strategies with the LIB Lead Impression Block from Marlin Oil Tools, a premier solution designed for the oil and gas industry. This innovative tool accurately captures impressions of downhole obstructions, enabling precise identification and efficient retrieval of fish. With its customizable design, efficient sediment clearance, and single-use optimization, the LIB Lead Impression Block is essential for any operation requiring detailed analysis of downhole conditions. Choose the LIB for its precision, adaptability, and effectiveness, backed by Marlin Oil Tools' comprehensive redress services to ensure your operations remain uninterrupted and successful. Why Choose the LIB Lead Impression Block from Marlin Oil Tools? Accurate Downhole Analysis: Delivers precise impressions for effective fish identification and tool selection. Customization for Specific Needs: Offers tailored solutions to match your unique well intervention requirements. Enhanced Operational Efficiency: Aids in quick and accurate decision-making for fishing operations, reducing time and costs. Reliable and Adaptable Tool: Designed with the flexibility to meet diverse operational challenges in various well environments. The LIB Lead Impression Block by Marlin Oil Tools represents the cutting edge in downhole fishing technology, providing a reliable, efficient, and accurate tool for enhancing well intervention outcomes. Incorporate the LIB into your toolkit for streamlined, successful fishing operations.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Anti-rotational internal Roll-on Connector for Coiled Tubing

Coiled Tubing Tools![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

ARC Coiled Tubing Connector | Anti-Rotational Roll-On Tool | Marlin Oil Tools The ARC (Anti-rotational internal Roll-on Connector) from Marlin Oil Tools serves as the essential link between the smooth lower end of coiled tubing (CT) and any downstream downhole tool required for well intervention projects in the oil and gas industry. Featuring a unique design, the ARC seamlessly connects the smooth-walled CT with the threaded interface of downhole tools, ensuring efficient and reliable operations in challenging wellbore environments. Key Features: Three grooves in the upper part of the connector facilitate the secure attachment and rolling of the coiled tubing, enhancing stability and operational performance. The lower part of the ARC is equipped with a threaded interface, enabling seamless connection with various downhole tools featuring connecting threads. O-rings positioned below the grooves provide a robust barrier, effectively sealing against in-line working pressures and preventing leaks during operations. A strategically placed slot along the grooves offers a significant advantage, allowing for the internal welding seam of the coiled tubing to be securely locked during connector installation. This anti-rotational feature ensures the stability of the connector and minimizes the risk of rotation during operation. The ARC Coiled Tubing Connector from Marlin Oil Tools is engineered to deliver exceptional performance, reliability, and sealing capabilities in oil and gas coiled tubing applications. Experience enhanced efficiency and confidence in your well intervention projects with the ARC connector from Marlin Oil Tools.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Coiled Tubing Hydraulic Vibration Tool

HVT Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the HVT (Hydraulic Vibration Tool) from Marlin Oil Tools: Revolutionizing Well Intervention and Completion Operations Marlin Oil Tools is proud to present the HVT (Hydraulic Vibration Tool), an advanced downhole tool designed to significantly enhance the efficiency and reach of well intervention and completion operations. The HVT stands out for its ability to create controlled vibrations when liquid is pumped through it, reducing the friction coefficient across the Bottom Hole Assembly (BHA) and ensuring extended reach in long horizontal wells. Here’s a closer look at the HVT’s features, benefits, and why it’s an essential tool for your oil and gas operations. Key Features of the HVT (Hydraulic Vibration Tool): Friction Reduction: The HVT generates vibrations that significantly reduce the friction coefficient, facilitating smoother and longer reach of the BHA in horizontal wells. Versatile Application: With options for larger diameters, the HVT can also be utilized as part of the casing shoe, ensuring that the casing reaches the planned depth during well completions. Exceptional Durability: Engineered to withstand harsh downhole conditions, the HVT is resistant to nitrogen, acid, and hydrogen sulfide, offering unlimited working time in challenging environments. Compact and Efficient: The tool’s short length makes it an ideal choice for operations requiring high maneuverability and efficiency. Elevate your well intervention and completion processes with the HVT (Hydraulic Vibration Tool) from Marlin Oil Tools, a cutting-edge solution designed to overcome the challenges of extended reach in horizontal wells. By creating controlled vibrations, the HVT reduces friction, enhancing BHA maneuverability and ensuring casing is accurately placed during well completions. Its resistance to nitrogen, acid, and hydrogen sulfide guarantees reliability in even the most demanding environments, while its compact design promotes operational efficiency. Choose the HVT for unparalleled performance and durability in your oil and gas operations. Why Choose the HVT from Marlin Oil Tools? Enhanced Operational Reach: Maximizes the effectiveness of well interventions in horizontal sections. Increased Completion Success: Assists in achieving accurate casing placement for optimal well completions. Reliable in Harsh Conditions: Offers unmatched durability against nitrogen, acid, and hydrogen sulfide. Streamlined Design: Facilitates ease of use and integration into existing operations without extensive modifications. The HVT (Hydraulic Vibration Tool) by Marlin Oil Tools represents the forefront of innovation in downhole tool technology, providing operators with a powerful solution to enhance the reach and success of well interventions and completions. Incorporate the HVT into your toolkit to achieve operational excellence and maximize the potential of your oil and gas wells.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Internal Roll-on Connector for Coiled Tubing

IRC Coiled Tubing Tool![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the Revolutionary IRC (Internal Roll-on Connector) by Marlin Oil Tools: Your Key to Efficient and Reliable Coiled Tubing Connections in the Oil and Gas Industry Marlin Oil Tools proudly presents the IRC (Internal Roll-on Connector), a cutting-edge solution engineered to enhance the efficiency and reliability of well intervention operations. Designed to seamlessly connect the smooth lower end of coiled tubing (CT) to any downhole tool, the IRC stands out for its innovative design and superior performance in the demanding environments of the oil and gas industry. Here's why the IRC is an essential tool for your well intervention operations. Key Features of the IRC (Internal Roll-on Connector): Innovative Groove Design: The IRC features unique grooves in its upper part, which are specifically designed for the secure fixing of coiled tubing through a rolling process. This design ensures a tight and reliable connection, crucial for the successful execution of well intervention tasks. Threaded Lower Part for Versatile Tool Attachment: Equipped with a threaded lower section, the IRC allows for easy and secure attachment of various downhole tools. This feature provides the versatility needed to adapt to different operational requirements, making the IRC a versatile tool in your well intervention toolkit. Enhanced Sealing with FKM 90 O-rings: To ensure the integrity of well operations, the IRC is fitted with two O-rings made from the high-quality FKM 90 material. This offers superior sealing capabilities, effectively isolating the connector's internal space from the annulus and preventing fluid leakage. Efficient Installation Process: The installation of the IRC is simplified and efficient, utilizing a mechanical tubing cutter with rolling wheels. This process not only ensures a secure connection but also minimizes downtime, allowing for quicker setup and transition between operations. Elevate your well intervention operations with the IRC (Internal Roll-on Connector) from Marlin Oil Tools, a leading innovator in coiled tubing technology for the oil and gas sector. Designed for the secure connection of coiled tubing to downhole tools, the IRC features a unique groove design for rolling fixation and a threaded lower part for versatile tool attachment. Equipped with dual O-rings made from durable FKM 90 material, it provides exceptional sealing, enhancing operational integrity. The IRC is engineered for easy installation, offering efficiency and reliability in well intervention tasks. Choose the IRC for a seamless, leak-proof connection in your coiled tubing operations. Why Choose the IRC from Marlin Oil Tools? Secure and Reliable Connection: The unique groove design ensures a robust connection between coiled tubing and downhole tools, critical for the success of well intervention operations. Operational Versatility: The threaded lower part enhances the IRC's compatibility with a wide range of downhole tools, offering operational flexibility. Superior Sealing Performance: Dual O-rings made from FKM 90 material provide outstanding sealing, protecting against fluid leakage and ensuring the safety of well operations. Streamlined Installation: Designed for efficiency, the IRC's installation process reduces operational downtime, enhancing productivity and operational flow. Marlin Oil Tools is dedicated to providing the oil and gas industry with innovative solutions like the IRC (Internal Roll-on Connector), designed to meet the rigorous demands of well intervention operations. Contact us today to discover how our advanced coiled tubing tools can optimize your operational efficiency and success.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Anti-rotational internal Roll-on Connector for Coiled Tubing

Coiled Tubing Tools![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

ARC Coiled Tubing Connector | Anti-Rotational Roll-On Tool | Marlin Oil Tools The ARC (Anti-rotational internal Roll-on Connector) from Marlin Oil Tools serves as the essential link between the smooth lower end of coiled tubing (CT) and any downstream downhole tool required for well intervention projects in the oil and gas industry. Featuring a unique design, the ARC seamlessly connects the smooth-walled CT with the threaded interface of downhole tools, ensuring efficient and reliable operations in challenging wellbore environments. Key Features: Three grooves in the upper part of the connector facilitate the secure attachment and rolling of the coiled tubing, enhancing stability and operational performance. The lower part of the ARC is equipped with a threaded interface, enabling seamless connection with various downhole tools featuring connecting threads. O-rings positioned below the grooves provide a robust barrier, effectively sealing against in-line working pressures and preventing leaks during operations. A strategically placed slot along the grooves offers a significant advantage, allowing for the internal welding seam of the coiled tubing to be securely locked during connector installation. This anti-rotational feature ensures the stability of the connector and minimizes the risk of rotation during operation. The ARC Coiled Tubing Connector from Marlin Oil Tools is engineered to deliver exceptional performance, reliability, and sealing capabilities in oil and gas coiled tubing applications. Experience enhanced efficiency and confidence in your well intervention projects with the ARC connector from Marlin Oil Tools.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the CBP Composite Bridge Plug from Marlin Oil Tools: The Cutting-Edge Solution for Temporary Well Barrier Operations Marlin Oil Tools is proud to present the CBP Composite Bridge Plug, a state-of-the-art downhole tool designed for optimal performance in oil and gas well operations. Engineered for easy installation using a hydraulic Setting Tool (STT), the CBP Composite Bridge Plug provides an effective temporary barrier within the well, isolating underlying intervals for enhanced operational control and safety. Key Features of the CBP Composite Bridge Plug: Efficient Installation: Utilizes a hydraulic Setting Tool (STT) for quick and secure deployment in oil and gas wells. Reliable Well Isolation: Designed to create a temporary barrier, effectively cutting off underlying intervals to manage wellbore integrity. Easy Removal Process: The composite bridge plug can be easily milled away using standard milling BHA, facilitating straightforward removal. Durable and Reliable Construction: Features collets with an easily drilled design, made from high-quality composite materials and reinforced with ceramic cylinders for increased durability. Proven Field Performance: The reliability and effectiveness of the CBP Composite Bridge Plug have been validated through extensive field work, ensuring dependable well isolation. Maximize your well intervention and maintenance operations with the CBP Composite Bridge Plug from Marlin Oil Tools, a premier solution for establishing temporary barriers in oil and gas wells. Engineered with advanced composite materials and ceramic cylinders, the CBP offers unmatched reliability and ease of installation using a hydraulic Setting Tool (STT). Whether you need to isolate wellbore intervals or ensure operational safety, the CBP Composite Bridge Plug's field-proven technology and easy milling process make it an indispensable tool for modern well operations. Choose the CBP for efficient, reliable, and easy-to-remove wellbore isolation. Why Choose the CBP Composite Bridge Plug from Marlin Oil Tools? Superior Wellbore Isolation: Offers effective temporary isolation, improving operational safety and control. Streamlined Installation and Removal: Designed for ease of installation and removal, reducing downtime and operational costs. Advanced Material Construction: Utilizes composite materials and ceramic cylinders for enhanced durability and reliability. Field-Tested Technology: Backed by extensive field testing, ensuring proven performance in various well conditions. The CBP Composite Bridge Plug by Marlin Oil Tools represents the forefront of downhole tool innovation, providing oil and gas operators with a reliable, efficient solution for temporary wellbore isolation. Incorporate the CBP into your operations to benefit from its superior performance and ease of use.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

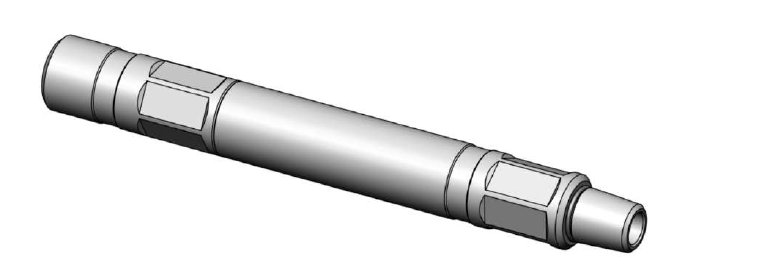

Introducing the SBA Straight Bar from Marlin Oil Tools: The Essential Downhole Tool for Enhanced Well Intervention Precision Marlin Oil Tools proudly presents the SBA Straight Bar, a specially designed downhole tool that revolutionizes well intervention operations. As an integral part of the Bottom Hole Assembly (BHA), the SBA Straight Bar addresses the critical challenge of coil tubing deformation, ensuring a straighter and more effective pathway for well intervention tools. Key Features of the SBA Straight Bar: Enhanced BHA Stability: The SBA Straight Bar provides the necessary rigidity and straightness to the BHA, minimizing the risk of deformation and ensuring smoother operations. Improved Wellbore Navigation: By maintaining a straighter path, the SBA Straight Bar significantly reduces the chances of the BHA resting against the well walls or encountering obstacles during transitions. Optimal Centering: Its rigid and straight design aids in better centering of the BHA within the wellbore, crucial for the precision of well intervention tasks. Seamless Passage: The SBA Straight Bar facilitates seamless passage through wellbore expansions and recessions, including critical points like blowout preventers, enhancing operational safety and efficiency. Versatile Integration: Designed for easy integration into any BHA configuration, the SBA Straight Bar is suitable for a wide range of well intervention activities, offering unparalleled adaptability. Elevate your well intervention strategies with the SBA Straight Bar from Marlin Oil Tools, a leading-edge solution designed to combat coil tubing deformation and ensure precise downhole operations in the oil and gas industry. The SBA Straight Bar enhances BHA stability, improves wellbore navigation, and ensures optimal centering and seamless passage through wellbore transitions. This tool is an indispensable addition to your BHA, providing the rigidity and straightness necessary for effective well intervention. Choose the SBA Straight Bar for a reliable, efficient, and versatile solution to well intervention challenges. Why Choose the SBA Straight Bar from Marlin Oil Tools? Superior Operational Precision: Ensures straighter coil tubing pathways for enhanced precision in well intervention tasks. Increased Operational Safety: Minimizes the risk of BHA hang-ups and obstructions, ensuring safer operations. Adaptability to Well Conditions: Capable of navigating through complex well architectures, including areas of expansion and recession. Streamlined Well Intervention: Promotes smoother, faster, and more efficient well intervention procedures. The SBA Straight Bar by Marlin Oil Tools represents the forefront of downhole tool technology, providing operators with the means to enhance well intervention accuracy and operational success. Incorporate the SBA Straight Bar into your well intervention toolkit to achieve superior performance and outcomes.

Buy

Made to Order

Manufacturer

New

API

Land Freight

Introducing the STM Step Mill from Marlin Oil Tools: Your Go-To Solution for Advanced Well Intervention and Milling Operations Marlin Oil Tools is excited to offer the STM Step Mill, a cutting-edge downhole tool specifically designed to enhance the efficiency of well intervention jobs. Whether you're dealing with bridge plugs, emergency lost equipment, or any obstruction softer than the mill's cutter, the STM Step Mill is engineered to grind and wash out these objects with unmatched efficiency. Key Features of the STM Step Mill: Superior Milling Performance: Designed to navigate and mill through downhole obstructions effectively, ensuring a clear wellbore for optimal production. Reduced Friction Surface: The STM Step Mill features a unique design with less friction surface, enabling it to mill out harder materials more efficiently than traditional tapered mills. Enhanced Weight-on-Bit Application: Its innovative design allows for higher weight on bit without the risk of stalling the downhole motor, maximizing milling effectiveness. Optimal Debris Removal: Equipped with multiple flushing holes, the STM ensures the efficient circulation of drilling fluid to remove milled particles from the well and cool the cutting edge. Durable Carbide Construction: Built with carbide welded onto the body, including options for crushed carbide and various insert designs, the STM Step Mill is designed for longevity and performance in challenging milling conditions. Comprehensive Redress Services: Marlin Oil Tools offers redress services for worn carbide, ensuring your STM Step Mill maintains peak performance throughout its service life. Elevate your well intervention strategies with the STM Step Mill from Marlin Oil Tools, a premier downhole tool designed for the oil and gas industry. Tailored for efficient grinding and removal of downhole obstructions, the STM Step Mill stands out with its reduced friction surface and ability to tackle harder materials without stalling the downhole motor. With its advanced carbide construction, optimal debris removal capabilities, and customizable insert options, the STM Step Mill is the ideal choice for increasing the ID of well restrictions and ensuring smooth wellbore conditions. Opt for Marlin Oil Tools’ STM Step Mill for enhanced well intervention and milling operations, backed by comprehensive redress services to extend tool life and performance. Why Choose the STM Step Mill from Marlin Oil Tools? Advanced Milling Efficiency: Offers unmatched efficiency in grinding down wellbore obstructions. Capability to Mill Harder Materials: Designed to tackle harder materials with greater ease compared to conventional mills. Higher Weight-on-Bit Flexibility: Enhances milling operations by allowing higher weight on bit without compromising tool performance. Customization and Longevity: Provides various carbide insert designs and redress services, ensuring a long service life tailored to your specific operational needs. The STM Step Mill by Marlin Oil Tools represents the forefront of downhole milling technology, offering a powerful solution for oil and gas operators focused on optimizing well intervention outcomes. Incorporate the STM Step Mill into your operations for smoother, more efficient wellbore preparation and obstacle management.

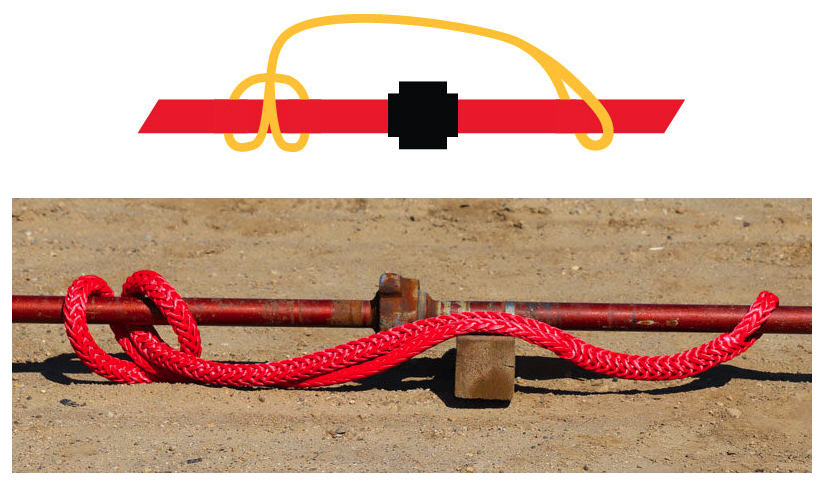

Safe-T-Whip Equipment Recertification

Annual Re-certificationAnnual Recertification Made Easy with Safe-T-Whip & Restraints Inc. At Safe-T-Whip & Restraints Inc., we understand the importance of maintaining the highest safety standards in the oilfield industry. That's why we offer a hassle-free and cost-effective Annual Recertification process for our soft rope restraints, ensuring that your equipment remains in peak condition and compliant with safety regulations. Convenient Shipping and Inspection: Our lightweight Safe-T-Whip Restraint system makes shipping to our recertification centers easy and inexpensive. Once received, each restraint undergoes a thorough inspection process, including visual checks and strength testing. This rigorous evaluation guarantees that your restraints are in top-notch condition to continue their crucial safety role. Serialized Registered Documentation: During the recertification process, each restraint is provided with serialized registered documentation. This ensures that every individual restraint is accounted for and easily identifiable. With our comprehensive database, we keep track of each restraint's purchase date and recertification status, giving you complete peace of mind and a reliable record for compliance purposes. Safety-First Inspection Tags: After successfully completing the recertification process, each restraint is equipped with a heavy-duty vinyl inspection tag. The tag is stamped with the new inspection date and securely zip-tied to the restraint. This safety tag serves as a visual indicator to safety inspectors that the restraint has been recertified, contributing to a safer work environment. Documentation Backup and Quick Access: We understand that maintaining documentation can be a challenge on-site. That's why Safe-T-Whip & Restraints Inc. takes the responsibility off your shoulders. We keep all recertification data securely backed-up, ensuring you have easy access to certificates and records whenever needed. Effortless Compliance: With our recertification process, you can be confident in meeting safety compliance requirements effortlessly. Our team is always available to assist with any queries, and should compliance or safety inspectors require it, we can quickly reissue certificates to help you stay compliant and on track. Choose Safe-T-Whip & Restraints Inc. for seamless and reliable Annual Recertification. Our dedication to safety and efficiency ensures that your safety restraints are always up to the task, providing you with peace of mind and full backup. Contact us today to schedule your Annual Recertification and experience safety without compromise.

Service

Made to Order

Service

New

API

Air Freight

![]() Provix in New Lowell

Provix in New Lowell

Illuminate Your Work with the Wisdom EX Cap Lamp – A Robust Solution from Provix Provix is excited to introduce the Wisdom EX Cap Lamp (model NWI-WLAMP3-EX), a high-performance lighting solution designed to meet the needs of professionals in various industries. This cap lamp combines superior illumination with the highest safety standards. Advanced Lighting for Challenging Environments The Wisdom EX Cap Lamp is equipped with a powerful 7.0Ah battery, providing long-lasting and reliable illumination for extensive work periods. Designed to operate efficiently in extreme conditions, it functions perfectly in temperatures ranging from -20°C to 40°C, making it ideal for a wide range of working environments. Compliance with Safety Standards Safety is paramount in professional settings, and the Wisdom EX Cap Lamp meets stringent safety standards. It is certified for Class I, II, and III, Division I, and complies with CSA C22.2 and UL 913 standards. This compliance ensures that the lamp is safe for use in hazardous locations where explosive gases or dust may be present. Durable and Reliable Built to withstand the rigors of industrial use, the Wisdom EX Cap Lamp is a durable and reliable choice for professionals. Its robust construction ensures it can endure the tough conditions often found in mining, construction, and other industrial settings. Ergonomic and User-Friendly Design Weighing in at a comfortable level, the Wisdom EX Cap Lamp is designed for ease of use and comfort, ensuring that it can be worn for extended periods without causing fatigue. Its ergonomic design makes it a practical choice for daily use in demanding work conditions. Versatile for Various Industrial Applications The Wisdom EX Cap Lamp is not only suitable for mining but also for other applications such as construction, oil and gas, and industrial maintenance. Its versatility and dependability make it an essential tool for a wide range of professionals. Get Your Wisdom EX Cap Lamp Today Upgrade your lighting equipment with the Wisdom EX Cap Lamp from Provix. Available now, this cap lamp is your solution for safe, efficient, and reliable lighting in any work environment.

Buy

In Stock

Manufacturer

New

ANSI

Air Freight

![]() PipeDNA in Houston

PipeDNA in Houston

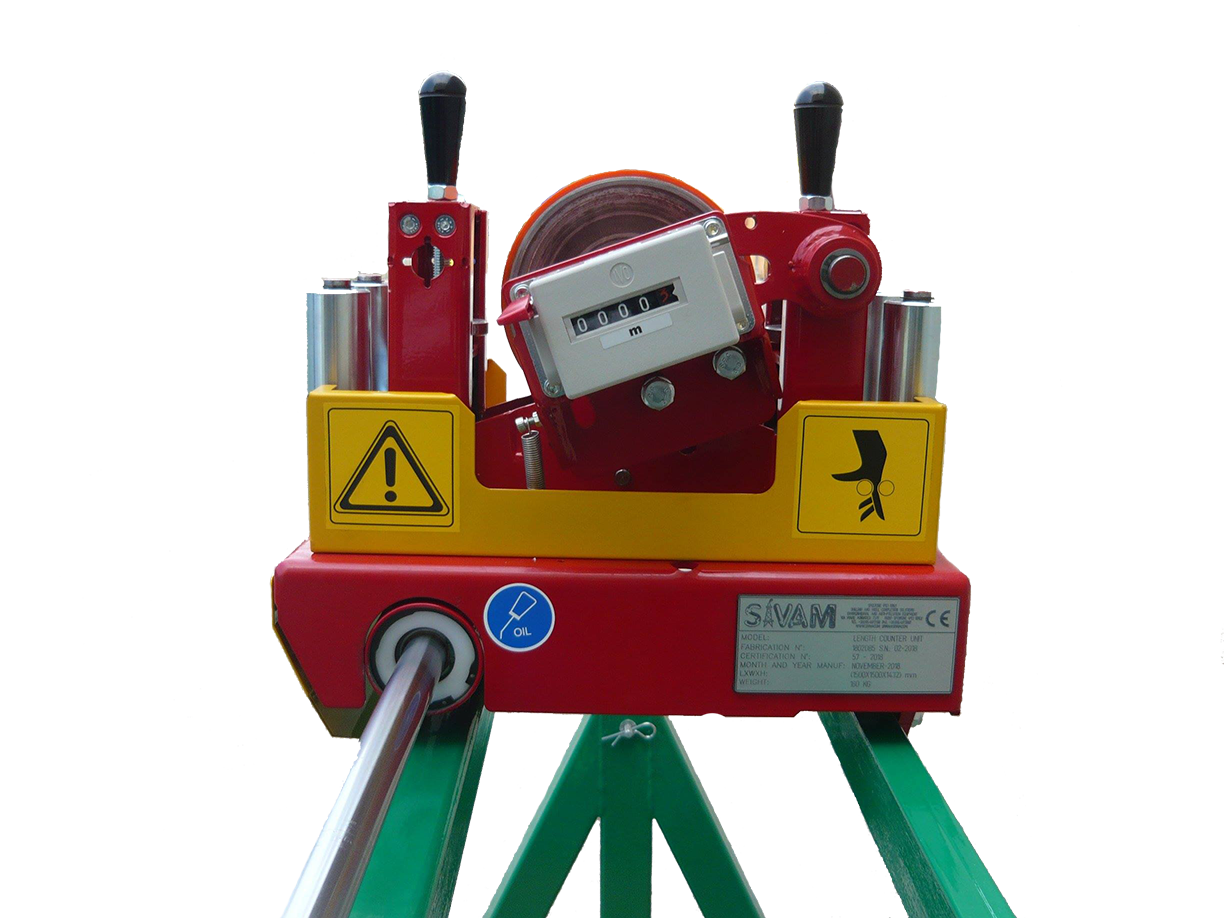

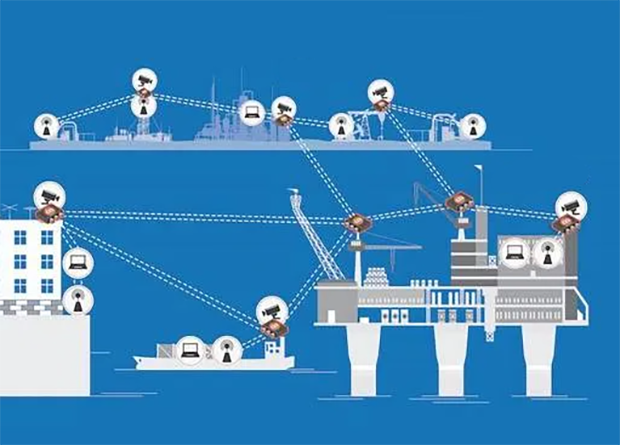

Streamlining OCTG Tubular Goods Management with PipeDNA: Boosting Efficiency and Reliability Efficient management of OCTG (Oil Country Tubular Goods) is critical in the oil and gas industry to ensure the success of drilling and production operations. Introducing PipeDNA, a smart cloud-based platform dedicated to managing pipe and tube throughout the oil and gas supply chain. With its powerful features and innovative technology, PipeDNA empowers stakeholders to proactively manage their OCTG tubular goods, increase visibility, and optimize their operations for enhanced efficiency and reliability. Comprehensive Inventory Management and Tracking: PipeDNA offers a comprehensive inventory management and tracking system specifically tailored for OCTG tubular goods. Gain full visibility into your OCTG inventory, including utilization, activity, and trends. By monitoring the status and location of each OCTG pipe, stakeholders can proactively plan for upcoming drilling projects, streamline logistics, and optimize inventory levels. PipeDNA enables accurate tracking, reducing the risk of stockouts, minimizing downtime, and maximizing operational efficiency. Efficient Logistics Management: With PipeDNA, stakeholders can efficiently manage all aspects of logistics operations related to OCTG tubular goods. From shipments to status tracking and documentation, PipeDNA simplifies the entire process, ensuring seamless coordination across multiple locations and parties involved. Furthermore, the platform facilitates pipe bundling, enabling stakeholders to optimize transportation and storage, minimizing costs and improving overall efficiency. Streamlined Inspection Management: PipeDNA's inspection management feature provides a centralized platform to manage inspection jobs for OCTG tubular goods across multiple sites. With real-time tracking and status updates, stakeholders can monitor the progress of inspection jobs, ensuring timely completion and adherence to quality standards. Additionally, the platform enables the management of inspection profiles, allowing for efficient scheduling, tracking, and reporting of inspection activities. Automated Tally Operations: Pipe tallying is a crucial process in OCTG tubular goods management, and PipeDNA simplifies this operation with automated tally operations. Stakeholders can create and manage tally operations within the platform, streamlining the process and eliminating manual calculations. By automating pipe tally jobs and workflows, PipeDNA saves time, reduces errors, and ensures accurate and up-to-date tally results, enhancing overall operational efficiency. Enhanced Identification and Traceability: PipeDNA offers quick and accurate identification of OCTG tubular goods, providing stakeholders with essential pipe details, activity history, and traceability documentation. With seamless integration of popular barcode standards such as UPC, EAN, and QR codes, PipeDNA enables easy identification and tracking of each pipe, ensuring precise inventory control and reducing the risk of misplaced or misused OCTG tubular goods. This enhanced traceability minimizes downtime and improves resource allocation. Designed for the Oil and Gas Industry: PipeDNA was specifically designed for stakeholders across drilling, manufacturing, and oilfield services, catering to their unique needs in OCTG tubular goods management. Whether you are a drilling contractor, oilfield rental company, oilfield and inspection service provider, steel pipe manufacturer, or pipe distribution and storage provider, PipeDNA offers tailored solutions to streamline your OCTG operations and drive efficiency. Leveraging Emerging Technologies: At its core, PipeDNA harnesses the power of today's emerging technologies to optimize OCTG tubular goods management processes. The platform seamlessly integrates with popular barcode standards, such as UPC, EAN, and QR codes, enabling efficient barcoding and labeling. Moreover, PipeDNA is RFID ready, supporting the integration of RFID technologies for accurate asset tracking. The platform also facilitates IoT data integration using the MQTT standard, enabling fast and reliable sensor data integration for enhanced decision-making. PipeDNA revolutionizes OCTG tubular goods management in the oil and gas industry, providing a smart cloud-based platform that enhances efficiency, reliability, and visibility. With its comprehensive inventory management, streamlined logistics operations, automated tallying, and robust identification and traceability features, PipeDNA empowers stakeholders to optimize their OCTG operations and make informed decisions based on real-time data. Leverage the power of PipeDNA and take your OCTG tubular goods management to new heights of efficiency and reliability.

Service

Currently in Use

Service

New

API

Air Freight

![]() Marlin Oil Tools in Calgary

Marlin Oil Tools in Calgary

Introducing the JWN Jet Wash Nozzle from Marlin Oil Tools: A Revolution in Well Intervention and Perforation Technology Marlin Oil Tools is proud to unveil the JWN Jet Wash Nozzle, an advanced downhole tool specifically engineered for precision well intervention and perforation tasks. As a critical component of the Bottom Hole Assembly (BHA), the JWN Jet Wash Nozzle is designed to enhance the efficiency of perforating casing or tubing by utilizing a high-speed jet of a gel-sand mixture directed at the well's inner casing wall. Here’s why the JWN Jet Wash Nozzle is a game-changer in the oil and gas industry. Key Features of the JWN Jet Wash Nozzle: Precision Perforation: The JWN Jet Wash Nozzle delivers a high-velocity jet stream of a gel-sand mixture, enabling precise and efficient perforation of the casing or tubing. Abrasive-Resistant Materials: Constructed from materials that resist wear from abrasive particles, ensuring longevity and reliability under harsh downhole conditions. Versatile Design Options: Available in a basic design for continuous circulation or a ball-activated design that opens nozzles only after a ball drop, providing flexibility for specific operational needs. Enhanced Well Productivity: By performing abrasive cuts through metal, cement, and part of the surrounding rock, the JWN enhances well connectivity and productivity. Seamless BHA Integration: Designed to run in hole as part of the BHA alongside other downhole tools, the JWN Jet Wash Nozzle is compatible with a wide range of well intervention equipment. Elevate your well intervention and perforation operations with the JWN Jet Wash Nozzle from Marlin Oil Tools, a leading-edge solution designed for optimal efficiency and precision in the oil and gas sector. Featuring abrasive-resistant nozzles and a high-speed gel-sand mixture jet, the JWN Jet Wash Nozzle precisely perforates casing and tubing, improving well productivity. With options for continuous circulation or ball-activated operation, this tool offers unparalleled flexibility and durability for your well intervention needs. Choose the JWN Jet Wash Nozzle for a reliable, efficient, and versatile solution in enhancing well connectivity and output. Why Choose the JWN Jet Wash Nozzle from Marlin Oil Tools? Targeted Perforation: Achieves precise perforation for improved fluid flow and well performance. Durable Construction: Built to withstand the rigors of abrasive materials, ensuring tool integrity and operational longevity. Operational Flexibility: Adapts to various well intervention scenarios with basic and ball-activated designs. Improved Efficiency: Reduces downtime and enhances well productivity through efficient and effective perforation. The JWN Jet Wash Nozzle by Marlin Oil Tools represents the pinnacle of well intervention technology, providing operators with a powerful tool for enhancing well integrity and performance. Incorporate the JWN Jet Wash Nozzle into your operations to achieve superior results in well perforation and intervention tasks.

Buy

Made to Order

Manufacturer

New

API

Land Freight

![]() CWB National Leasing in Winnipeg

CWB National Leasing in Winnipeg

Enhance Your Workspace with Desk Leasing from CWB National Leasing Creating an Efficient and Productive Office Environment with Flexible Furnishing Solutions For businesses looking to create or revamp their office spaces, having the right desks is crucial for ensuring a productive and comfortable work environment. Leasing desks through Canadian Western Bank (CWB) National Leasing offers a flexible, cost-effective, and practical solution for businesses seeking to optimize their workspace. Here’s how leasing desks can benefit your business: 1. Quick Access to Modern Office Furniture CWB National Leasing values the importance of a well-equipped office space in enhancing productivity. They offer a fast leasing process, with decisions typically made within 48 hours of your application. This rapid service ensures that your desks can be delivered and set up quickly, transforming your office space without significant delays. 2. Increased Financial Flexibility Leasing desks with CWB National Leasing enhances your financial power. It allows you to conserve capital by opting for periodic payments over a large upfront purchase. The flexibility to add extra features or accessories to your desks for a small payment increase allows for customization to meet specific office needs and ergonomic considerations. 3. Effective Cash Flow Management Manageable lease payments over the term mean your desks start contributing to your business’s efficiency while they're being paid off. This approach helps maintain a balanced expense-to-revenue ratio, essential for business growth and financial stability. 4. Customizable Payment Plans CWB National Leasing offers a variety of payment options, including seasonal, semi-annual, or annual plans, tailored to your business’s financial cycle. This flexibility is particularly beneficial for businesses with variable or seasonal income, ensuring that payments are practical and fit your financial situation. 5. Potential Tax Benefits Leasing desks can offer tax advantages, such as the ability to expense lease payments instead of capitalizing the cost of the equipment. Consulting with a tax advisor is advisable to understand how leasing can optimize your business’s tax position. Conclusion Choosing to lease desks through CWB National Leasing is a strategic decision that equips your business with essential office furniture while maintaining financial flexibility. It ensures access to high-quality desks, vital for creating a productive and comfortable working environment, without the financial strain of a large upfront investment. This leasing approach enables enhanced office aesthetics, improved employee comfort, and increased overall productivity, helping your business to thrive in a competitive corporate landscape.

Service

In Stock

Service

New

ISO

Safe-T-Whip Installation Training

Restraint TrainingEmpowering Your Team with Installer Training and Certification At Safe-T-Whip & Restraints Inc., safety is at the heart of everything we do. We believe that a well-trained and qualified workforce is the cornerstone of a safe and successful oilfield operation. That's why we offer comprehensive On-Site Qualified Installer Training and Certification programs to ensure that your team is equipped with the knowledge and skills they need to handle our safety restraints with confidence. Comprehensive Training, Complete Confidence: Our training program covers all the essential aspects of Safe-T-Whip usage, maintenance, and safety procedures. We leave no stone unturned, ensuring that your team is well-versed in all the critical elements of working with our safety restraints. Topics Covered: During our training sessions, your team will learn about: • Proper use of Safe-T-Whip restraints to ensure maximum safety and effectiveness. • Tags and identification for easy recognition and compliance with safety protocols. • Inspection techniques to identify any potential issues or concerns. • Proper installation and use of anchor points for secure and reliable restraint. • Maintenance and cleaning procedures to keep the restraints in optimal condition. • Leak repair measures to address any unforeseen incidents promptly. • Annual inspection practices to maintain the highest safety standards over time. Certified for Success: After completing our comprehensive training program, your team members will receive certification, recognizing their proficiency and qualification as Safe-T-Whip installers. This certification is a testament to their commitment to safety excellence and adherence to industry best practices. On-Site Convenience: We understand that your operations may have specific needs and challenges. That's why we bring the training directly to your site, ensuring convenience and relevance for your team. Our expert trainers will work with your personnel, addressing site-specific concerns and scenarios to ensure practical application of the training. Safety First, Always: With Safe-T-Whip Installer Training and Certification, you can be confident that your team is prepared to prioritize safety in every aspect of their work. From installation and inspection to maintenance and repair, our training equips your team with the expertise they need to create a safer work environment for everyone. Choose Safe-T-Whip & Restraints Inc. for top-notch safety solutions and industry-leading training. Contact us today to schedule your On-Site Qualified Installer Training and Certification and take the first step towards a safer, more secure oilfield operation. Together, we build a safer future for the industry.

Service

Made to Order

Service

New

API

Air Freight

HR & Performance Management Platform

KEY360![]() KEY360 Inc in New York, NY

KEY360 Inc in New York, NY

KEY360 Inc offers a single integrated Business Management Platform comprising Business Intelligence, Project Management, Big Data & Analytics, ERP, Behaviour and Strategy Modification. - Over 140 Business and Project Management Systems on one platform available - Unique and extremely effective workflow engine - Remarkable “BIG DATA” and bulk transaction capability - Integrated Real Time reporting and dashboarding - Multi-company platform allows all project users to integrate seamlessly KEY Differentiators: - KEY360 Provides an exceptional opportunity for your organisation to attract new clients and build long terms relationships. - KEY360 is a Microsoft Gold Partner and Approved Microsoft Co-Sell Partner and can be purchased directly from the below online marketplaces: - Microsoft AppSource: KEY360 Capital Management Projects - Azure Marketplace: KEY360 Capital Management Projects - KEY360 is reputedly the most comprehensive and versatile Capital Project Management, Business Digitalization & Business Optimization solution available.

Service

In Stock

Service

New

ISO

Simplify Your International Transactions

Business FX Services![]() Dunbridge Financial in Oakville

Dunbridge Financial in Oakville

Unlock Global Success with Dunbridge Financial's Business Services: Simplify Your International Transactions As a thriving international business, you understand the importance of efficient and cost-effective financial solutions. At Dunbridge Financial, we are your trusted partner in navigating the complexities of global commerce. Our Business Services are tailor-made to help you streamline your international transactions, ensuring you stay ahead of the competition and achieve new heights of success. Pay Invoices with Foreign Exchange Advantage Paying suppliers in local currency gives you a strategic edge, providing access to foreign exchange advantages and better pricing. With Dunbridge Financial, you can take full advantage of these benefits, empowering your business with optimized financial transactions. One Platform for All Your International Business Needs With Dunbridge Financial, managing your international business has never been easier. Experience the convenience of our elegant platform, where you can collect, manage, and pay foreign currencies seamlessly, all from one centralized location. Say goodbye to complexity and uncertainty in your international dealings - we are here to make it simple and secure. Concierge Customer Service - Your Success Is Our Priority At Dunbridge Financial, we believe in embedding ourselves with our customers to understand their unique needs thoroughly. Every customer is assigned a dedicated account manager who will work closely with you to develop a tailored payment strategy that aligns with your business goals. Take the complexity out of your FX payment strategy and let us guide you towards success. Fast and Secure International Payments Time is of the essence in the global marketplace, and Dunbridge Financial is here to ensure your international payments are fast and secure. With our global banking relationships, you can make cost-effective international payments to over 100 currencies and 120 countries. Our market-leading platform, compliant with ISO27001, guarantees your transactions are safe and protected. Multi-Currency Accounts in Your Company's Name Simplify your financial management with multi-currency accounts, all in your company's name. With Dunbridge Financial, you can receive and manage multiple currency balances seamlessly within a single account. Real accounts in your company's name enable you to receive like a local, with IBAN, ACH, and SEPA capabilities. Additionally, you have the flexibility to transfer funds between currencies as needed, empowering you with financial agility. Streamline with Mass Payments Take the burden out of your accounts payable processes with Dunbridge Financial's Mass Payments feature. Easily upload, manage, and pay up to 1000 payees at once, saving time and effort in your financial operations. Why Choose Dunbridge Financial? Dunbridge Financial is more than just a financial service provider - we are your strategic partner in achieving global success. When you choose us, you gain access to: • A free global business account within 24 hours • An elegant platform that simplifies international transactions • Expert concierge customer service that is tailored to your needs • Fast and secure international payment capabilities • Multi-currency accounts for seamless financial management • Streamlined mass payments to optimize your AP processes Join Us Today and Thrive in the Global Arena Embrace the power of Dunbridge Financial's Business Services and take your international business to new heights. Simplify your international transactions, seize foreign exchange advantages, and secure better pricing for your business. With us by your side, you'll experience seamless financial management, leaving you with more time to focus on what truly matters - your business's growth and success. Empower your business with Dunbridge Financial. Sign up now and unlock the keys to global triumph. Your journey to success begins here.

Service

Made to Order

Service

New

ISO

Air Freight

![]() CWB National Leasing in Winnipeg

CWB National Leasing in Winnipeg